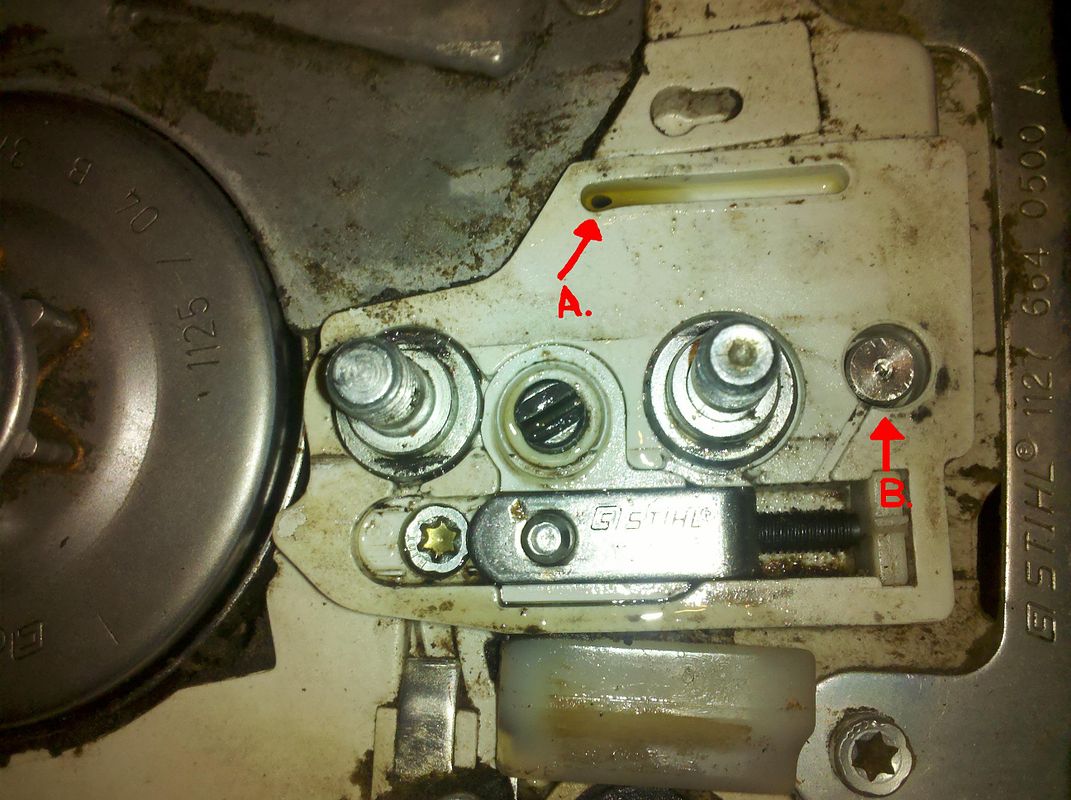

See pic for reference

I ran my Stihl MS310 today, cut an old dead Elm Tree, about 2 cords worth. Half rotted and very dusty. I noticed that I wasn't seeing as much bar oil as I normally do, but the level of bar oil was going down with run time so I didn't think much of it. So tonight I tore it down a little. I took the bar and chain off, cleaned out a bunch of saw dust then ran the power head to see where bar oil was coming from.

I am under the assumption oil is supposed to come from both "A" and "B"

My saw is only sending oil out of port "A".

Is bar oil indeed supposed to be coming out of "B"as well?

I figure a good cleaning is in order, but want to double check before draining the tank and cleaning everything out.

Thanks in advance

I ran my Stihl MS310 today, cut an old dead Elm Tree, about 2 cords worth. Half rotted and very dusty. I noticed that I wasn't seeing as much bar oil as I normally do, but the level of bar oil was going down with run time so I didn't think much of it. So tonight I tore it down a little. I took the bar and chain off, cleaned out a bunch of saw dust then ran the power head to see where bar oil was coming from.

I am under the assumption oil is supposed to come from both "A" and "B"

My saw is only sending oil out of port "A".

Is bar oil indeed supposed to be coming out of "B"as well?

I figure a good cleaning is in order, but want to double check before draining the tank and cleaning everything out.

Thanks in advance