Hi I'm new to this site....

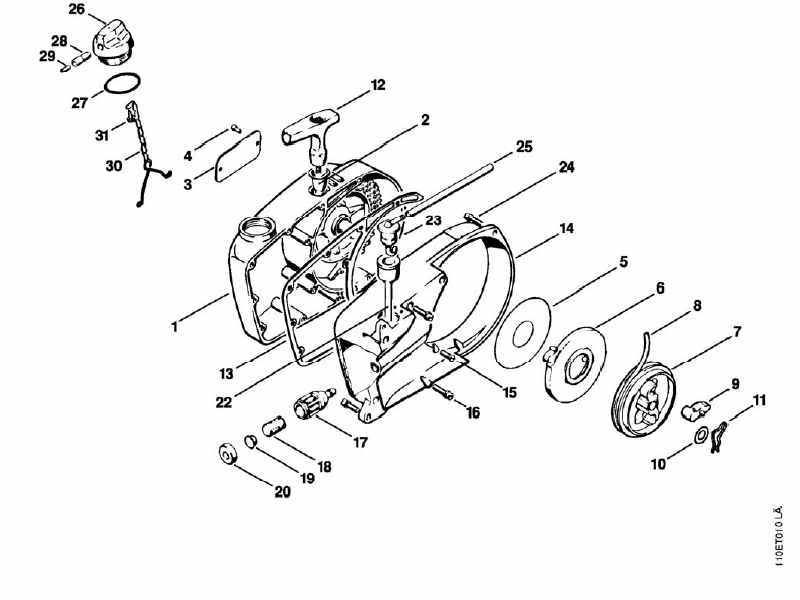

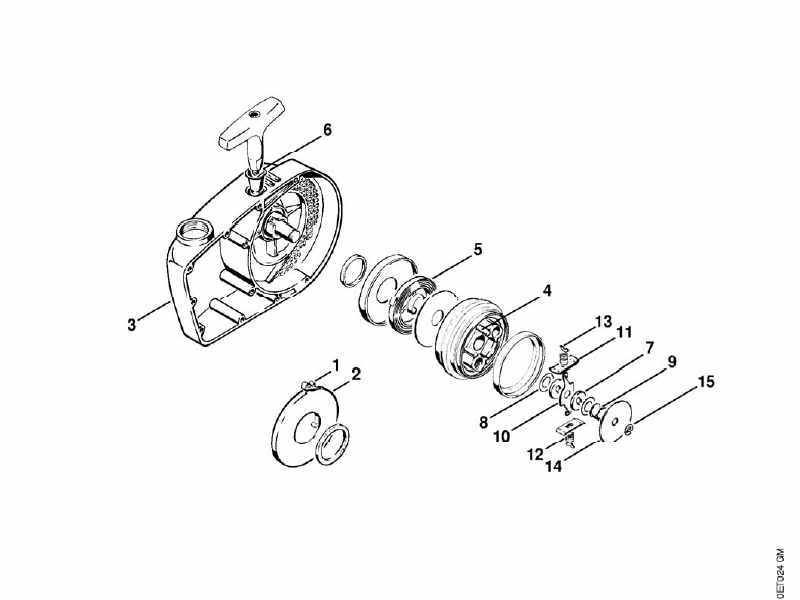

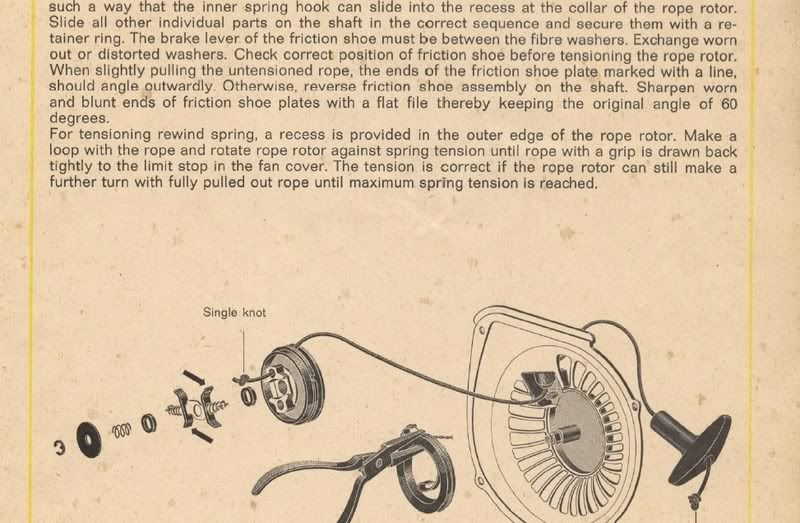

I was cleaning my Stihl hand recoil starter rope assembly and removed the sideplate cleaned it then put back together ...started it O.K. then tried to start it again and pulled the hand pull and nothing caught....did not grab. so took it apart again and checked out the pawles and when I pull noticed they go outward to grab the plastic inner surface of the flywheel...but prehaps its isn't going out far enough to grab. Cause it moves freely when I pull it.

Only loose part was the plastic sleeve that inserts between the flywheel and the pull/recoil...

Any ideas I might look at to get it to grab again?

thank you..

I was cleaning my Stihl hand recoil starter rope assembly and removed the sideplate cleaned it then put back together ...started it O.K. then tried to start it again and pulled the hand pull and nothing caught....did not grab. so took it apart again and checked out the pawles and when I pull noticed they go outward to grab the plastic inner surface of the flywheel...but prehaps its isn't going out far enough to grab. Cause it moves freely when I pull it.

Only loose part was the plastic sleeve that inserts between the flywheel and the pull/recoil...

Any ideas I might look at to get it to grab again?

thank you..