SCoupe

ArboristSite Lurker

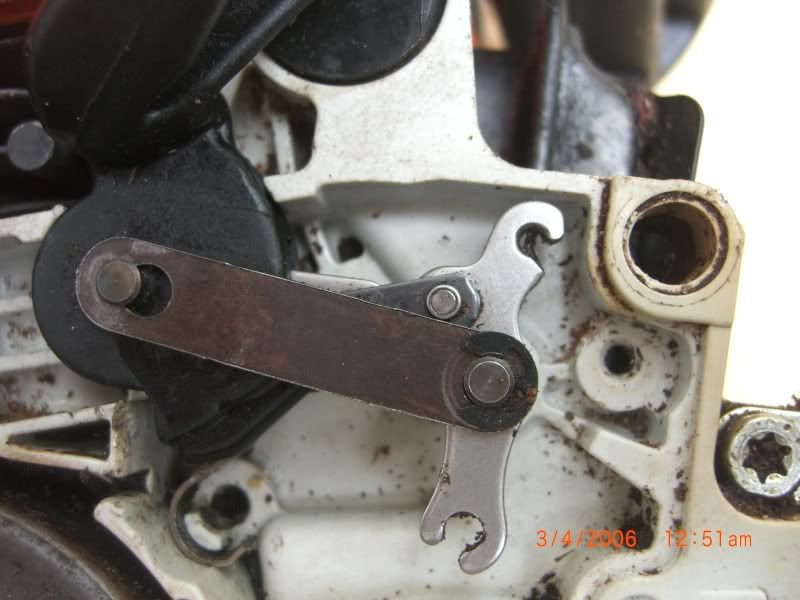

I've hit an impasse while reinstalling my brake handle on my Stihl MS250 and would appreciate any advice. The lever with the flexible links will not clear the strap when I have re-assembled it. The links hit the lever, there is insufficient clearance to allow the lever to pass under the strap. Picture(s) will hopefully show the problem.

Last edited: