Daninvan

ArboristSite Operative

Another so-so day weather wise, at least not raining when we started, although as I stepped out of the house my wife did admonish me to take my hat. There was a bit of blue sky to the west first thing but it did not last long.

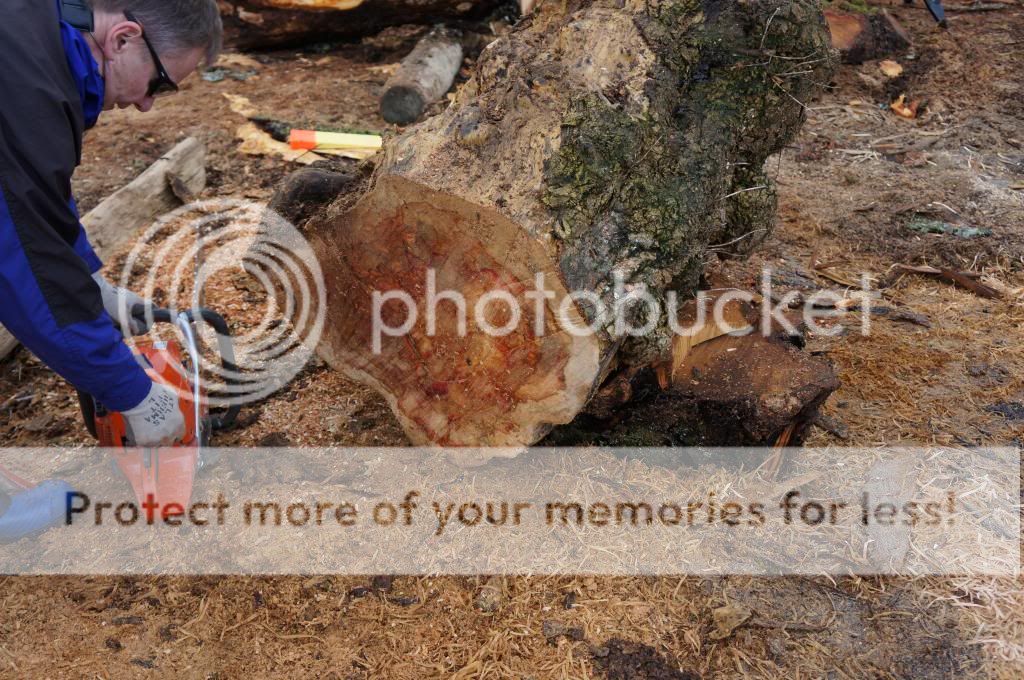

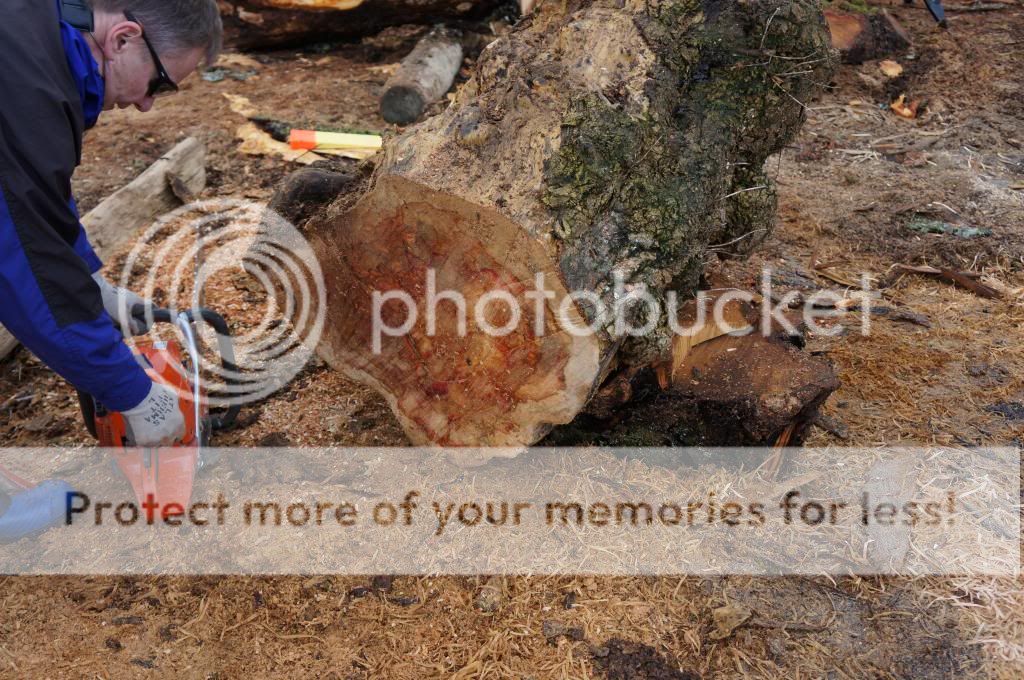

Got down to the beach and had a couple logs set up, a cherry and a decent sized piece of box elder. The box elder had been lying around since the summer, so I was worried that it might have quite a bit of staining in it.

The bark peeled off both very quickly, and I cut the end off the BE to get past any cracks or embedded sand that might have been there. Colour looked very promising, the excitement level started to go up.

Since the BE had a lot of rot at the other end, we cut it half to try and get past the rot. Despite the one end looking good, the log was full of rot. So we decided to not slab it, but just to freehand out some bowl blanks.

Next we turned our attention to the cherry.

First pass looked promising.

In fact it went very quickly and before we knew it, we had four nice cherry slabs. The 3120 ran beautifully, the chain was sharp, the mill was tight, everything came together as it should for a change! However, the 385 we used for cutting out the bowl blanks decided to get stuck on full throttle. Rather than fiddle with it there, we switched to another saw.

We were done in record time with the cherry, so I arranged for another cherry log to be set up. This one had a lot of mud on it and the bark was a ton of work to get off. Finally got that done, set the guideboard on, and did the first cut. Started on the second cut, the saw was in need of sharpening, so we stopped the cut and I sharpened. We got nearly through the log and the chain broke. It just died in the cut, didn't whip around or anything. I think that's only the second time that has happened while I was pushing the saw. Not really sure why it happened.

Got down to the beach and had a couple logs set up, a cherry and a decent sized piece of box elder. The box elder had been lying around since the summer, so I was worried that it might have quite a bit of staining in it.

The bark peeled off both very quickly, and I cut the end off the BE to get past any cracks or embedded sand that might have been there. Colour looked very promising, the excitement level started to go up.

Since the BE had a lot of rot at the other end, we cut it half to try and get past the rot. Despite the one end looking good, the log was full of rot. So we decided to not slab it, but just to freehand out some bowl blanks.

Next we turned our attention to the cherry.

First pass looked promising.

In fact it went very quickly and before we knew it, we had four nice cherry slabs. The 3120 ran beautifully, the chain was sharp, the mill was tight, everything came together as it should for a change! However, the 385 we used for cutting out the bowl blanks decided to get stuck on full throttle. Rather than fiddle with it there, we switched to another saw.

We were done in record time with the cherry, so I arranged for another cherry log to be set up. This one had a lot of mud on it and the bark was a ton of work to get off. Finally got that done, set the guideboard on, and did the first cut. Started on the second cut, the saw was in need of sharpening, so we stopped the cut and I sharpened. We got nearly through the log and the chain broke. It just died in the cut, didn't whip around or anything. I think that's only the second time that has happened while I was pushing the saw. Not really sure why it happened.