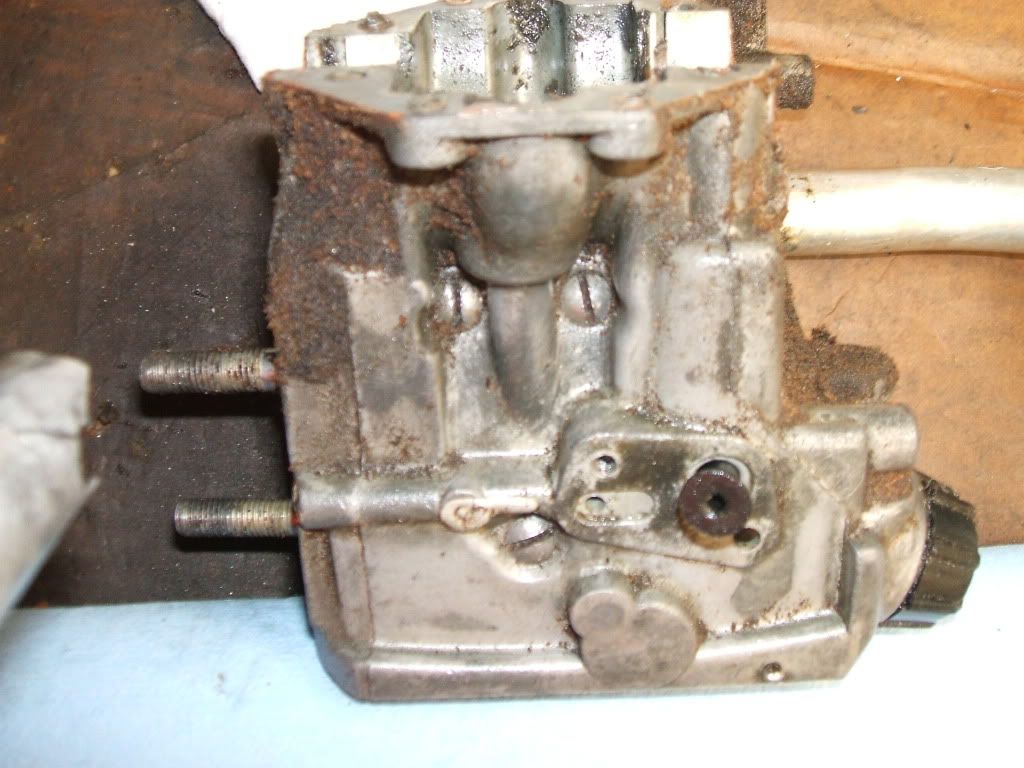

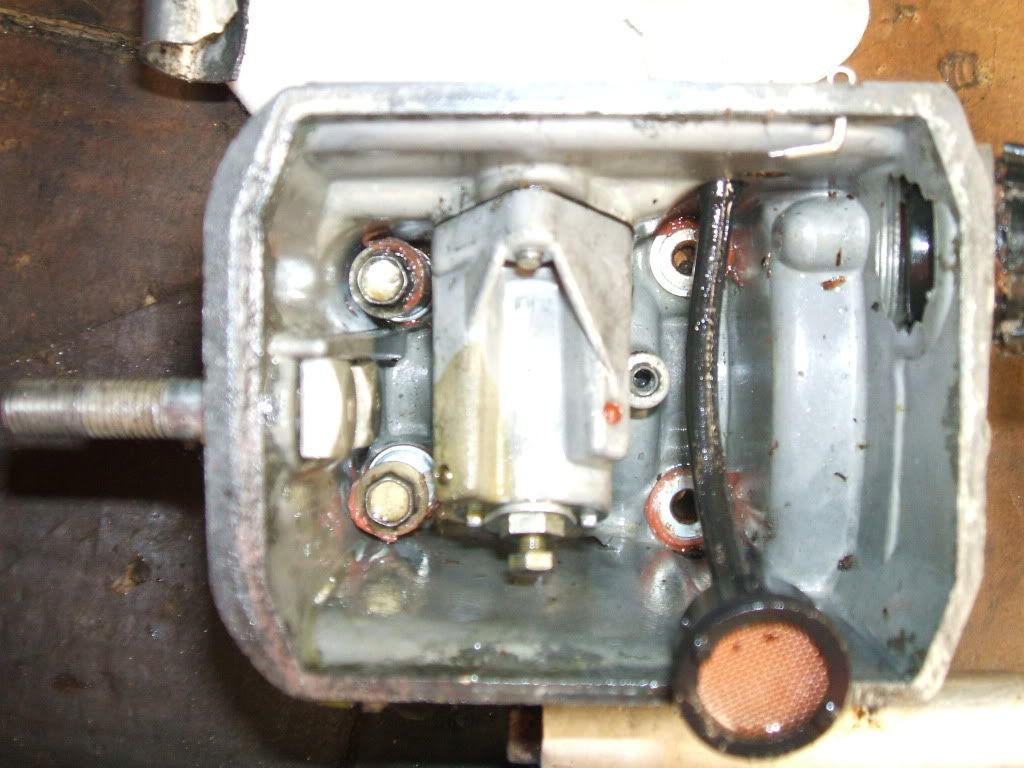

There have been a couple of threads lately discussing McCulloch 10 Series saws and oiler issues. I had a little time to take a few photos and thought I try to show how the parts are supposed to work.

The first attachments are the pages from the manual describing the oiler function. The only instruction missing is the the last note that says tighten the screw on the oil pump cover to 55-60 In/Lb.

Sorry, I don't know any way to load these .pdf files to make them automatically appear.

Mark

The first attachments are the pages from the manual describing the oiler function. The only instruction missing is the the last note that says tighten the screw on the oil pump cover to 55-60 In/Lb.

Sorry, I don't know any way to load these .pdf files to make them automatically appear.

Mark