40YearHomelite

ArboristSite Member

I bought a DCS 6421 with the 84cc BB kit from Bailey's a little less than a year ago. I probably put about 10 hours on the 64cc and another 10 on the 84cc. I was recently bucking an old hickory when the saw suddenly lost compression and died. I gave a few pulls on the starter rope and the piston seized. F.

Now, when I say it seized, I mean it SEIZED. I had to strap the saw to a barn pole, strap a wench to another pole, and wench the cylinder off. This is what it looked like:

Apparently, the groove in the piston that holds the wrist pin circlip broke off, flinging bits of piston and circlip.

Thanks to Bailey's excellent customer service, I received a new BB kit free of charge. When I installed this one today, I made SURE to not gouge the piston, not strain the clip, and align the clip's gap at 12 o' clock.

While I was at it, I measured the squish at 0.051" with the metal base gasket for 150psi; 0.030" without the gasket for 165psi. I left the gasket off and sprayed on several layers of Permatex copper gasket compound. I re-tuned the carb and now the saw runs considerably stronger than it did last time with the gasket and lower compression.

Lesson learned: be careful with those dang circlips, align the gap at 6 or 12 o'clock, and go to Bailey's every chance I get

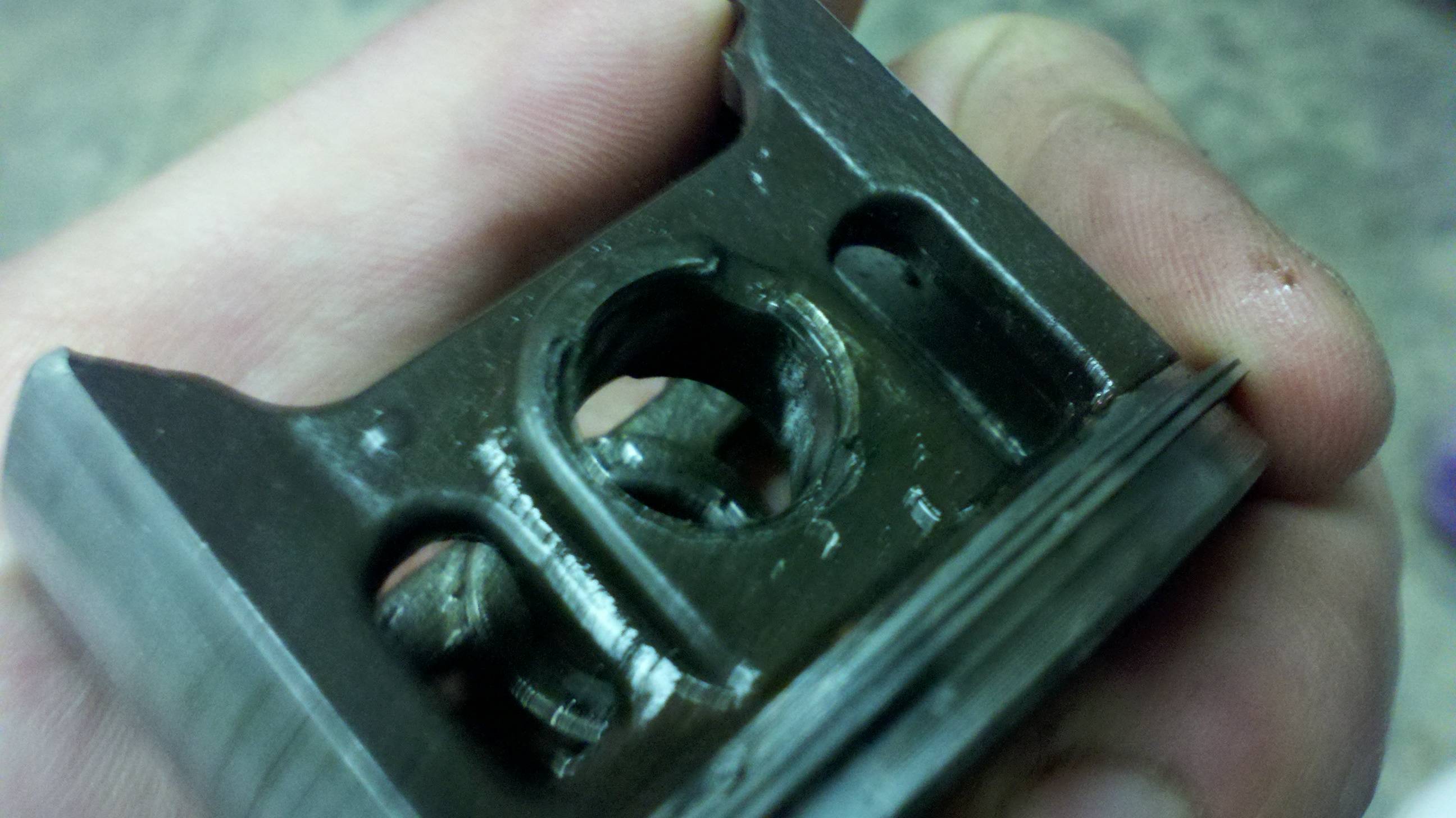

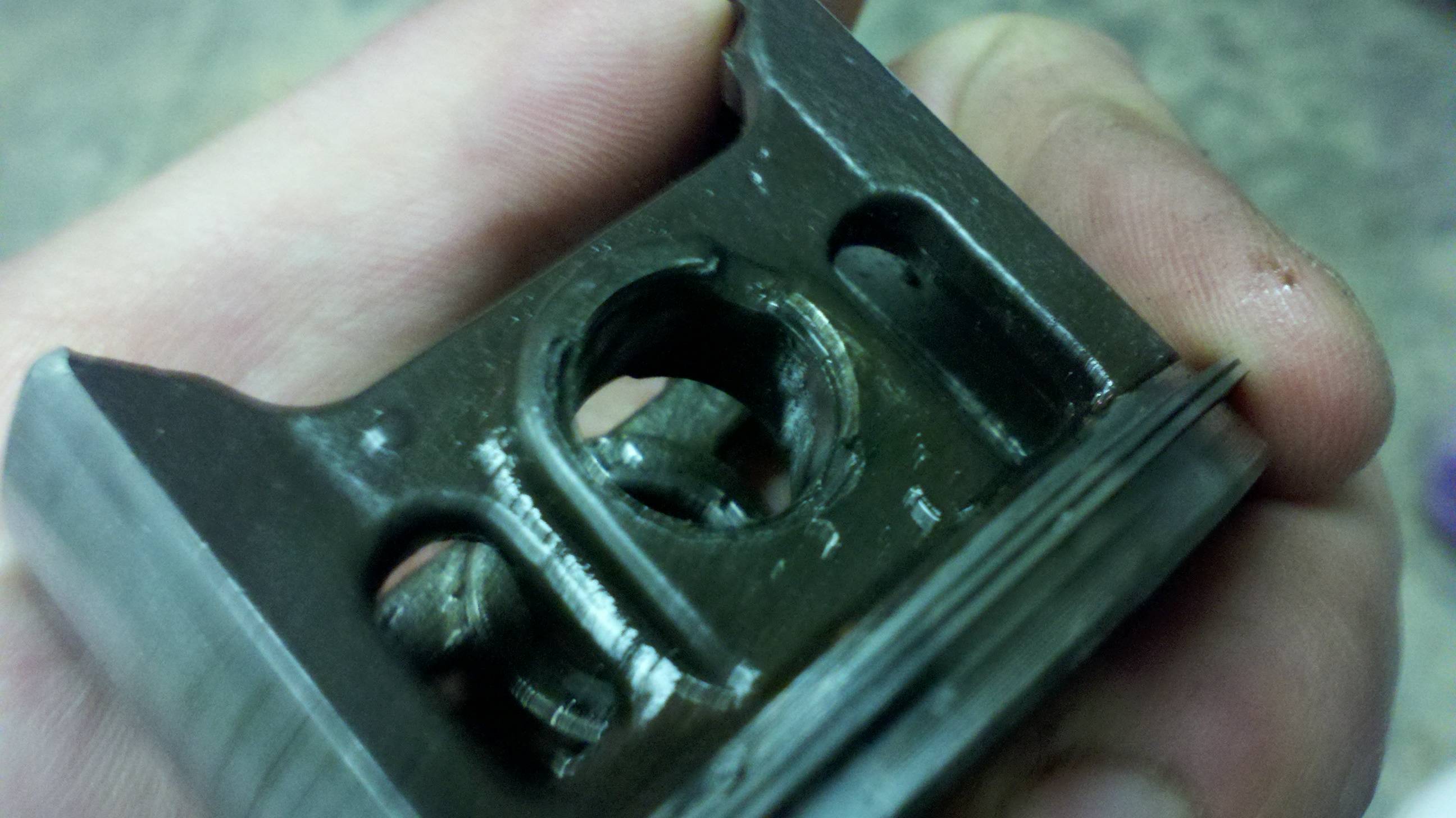

EDIT: pics of the broken circlip groove

Now, when I say it seized, I mean it SEIZED. I had to strap the saw to a barn pole, strap a wench to another pole, and wench the cylinder off. This is what it looked like:

Apparently, the groove in the piston that holds the wrist pin circlip broke off, flinging bits of piston and circlip.

Thanks to Bailey's excellent customer service, I received a new BB kit free of charge. When I installed this one today, I made SURE to not gouge the piston, not strain the clip, and align the clip's gap at 12 o' clock.

While I was at it, I measured the squish at 0.051" with the metal base gasket for 150psi; 0.030" without the gasket for 165psi. I left the gasket off and sprayed on several layers of Permatex copper gasket compound. I re-tuned the carb and now the saw runs considerably stronger than it did last time with the gasket and lower compression.

Lesson learned: be careful with those dang circlips, align the gap at 6 or 12 o'clock, and go to Bailey's every chance I get

EDIT: pics of the broken circlip groove

Last edited: