Mastermind

Work Saw Specialist

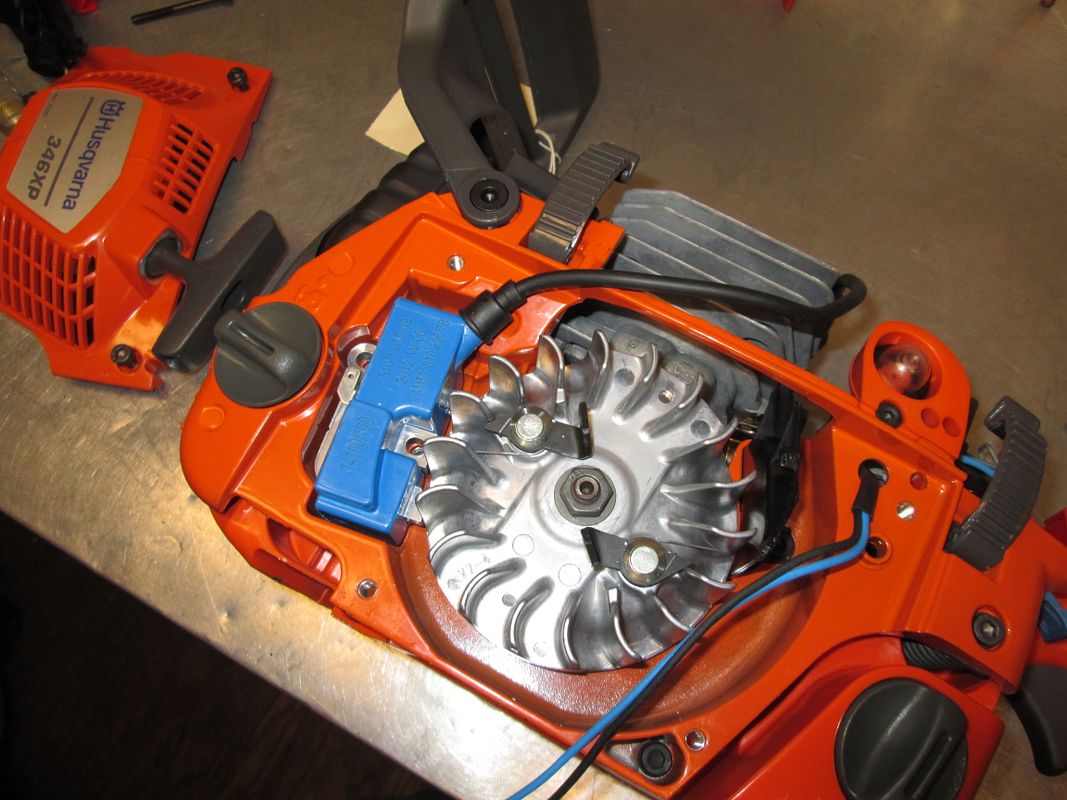

I've done so many 346XPs that I don't think about doing a thread on them when they come through. I thought I might share my version of the 346XP build. Now keep in mind that everyone has their own ideas about what makes a great running 346XP.......just because I might do something a bit different doesn't make my way right or wrong.....just my way.

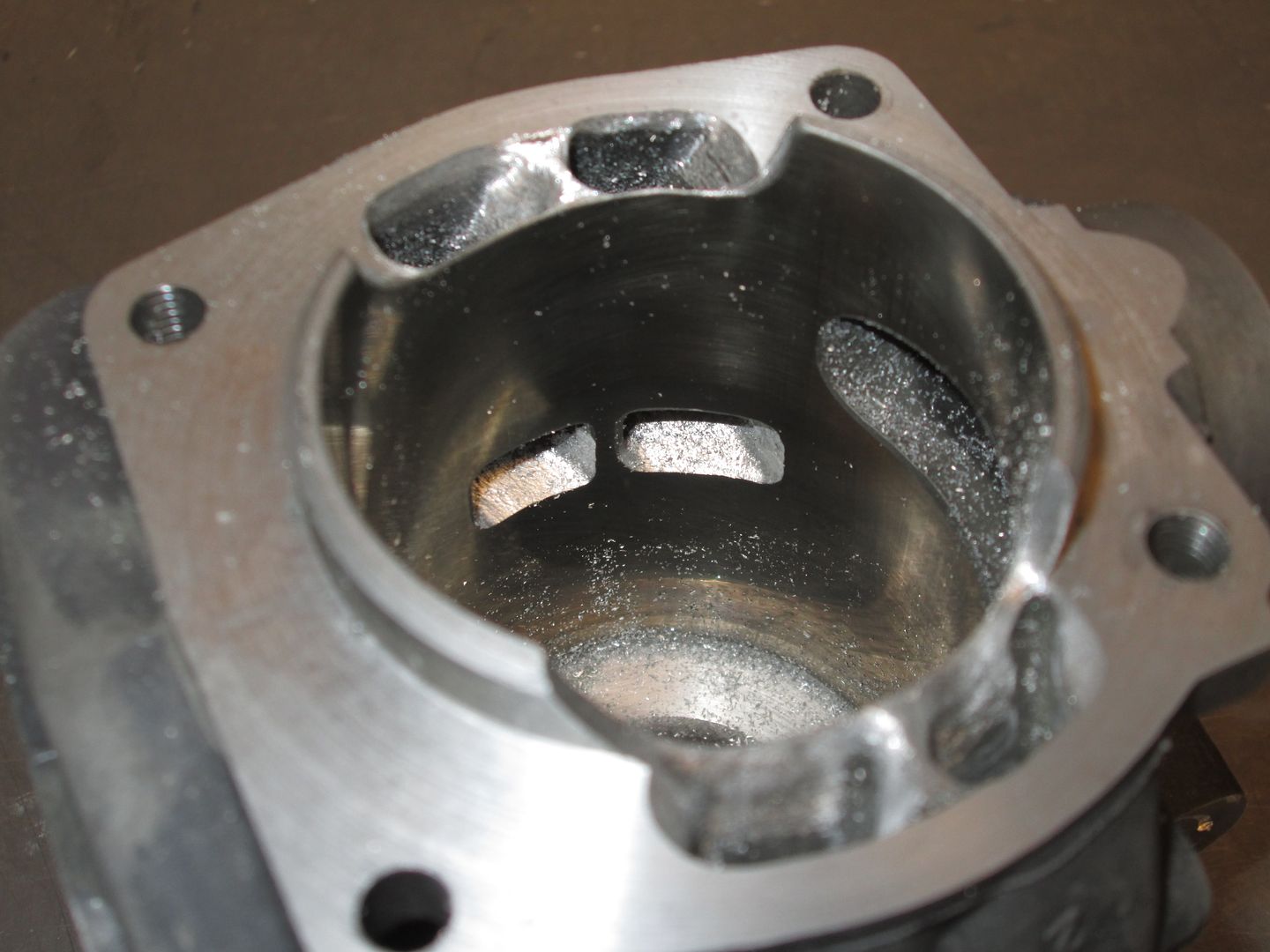

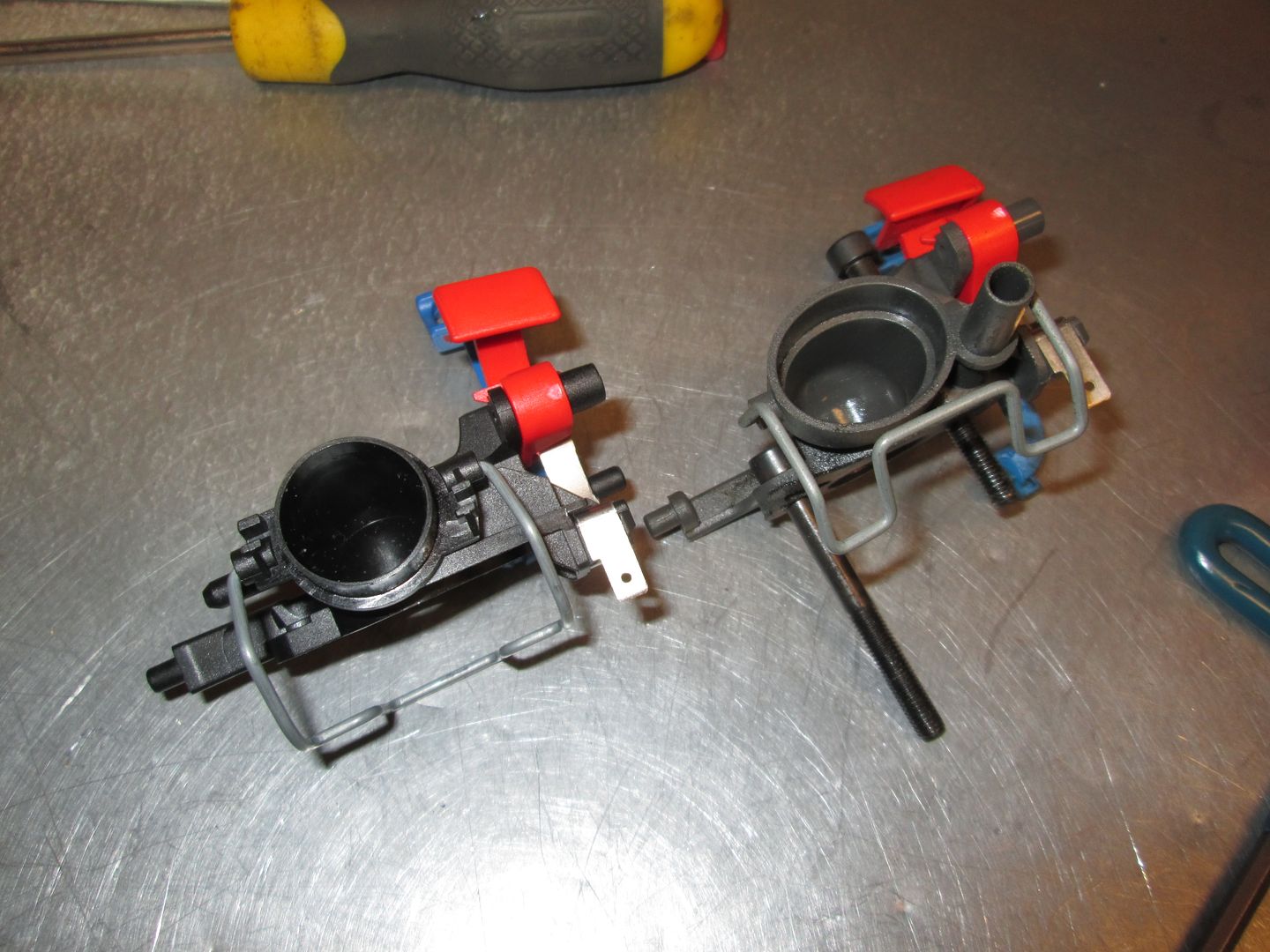

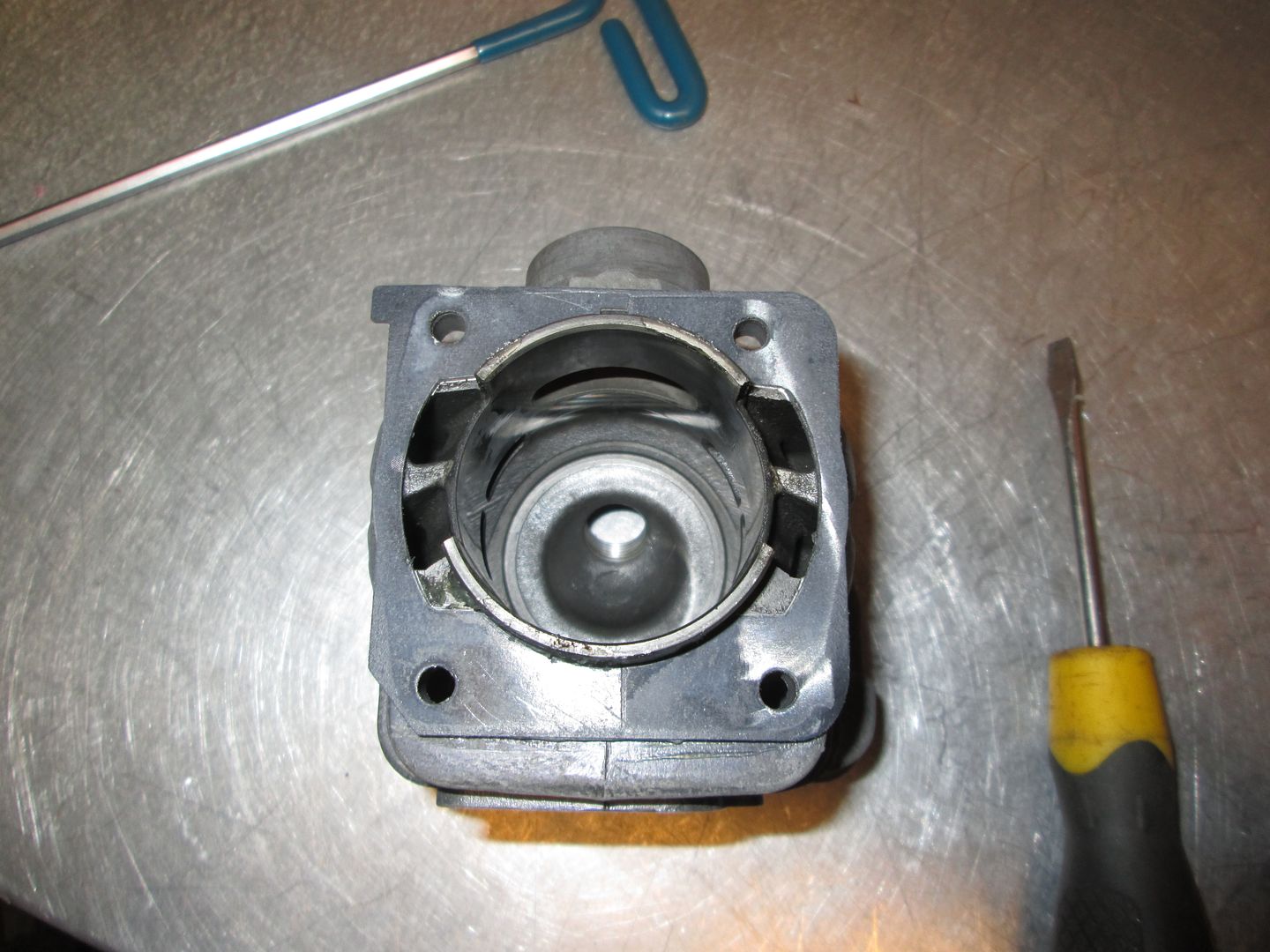

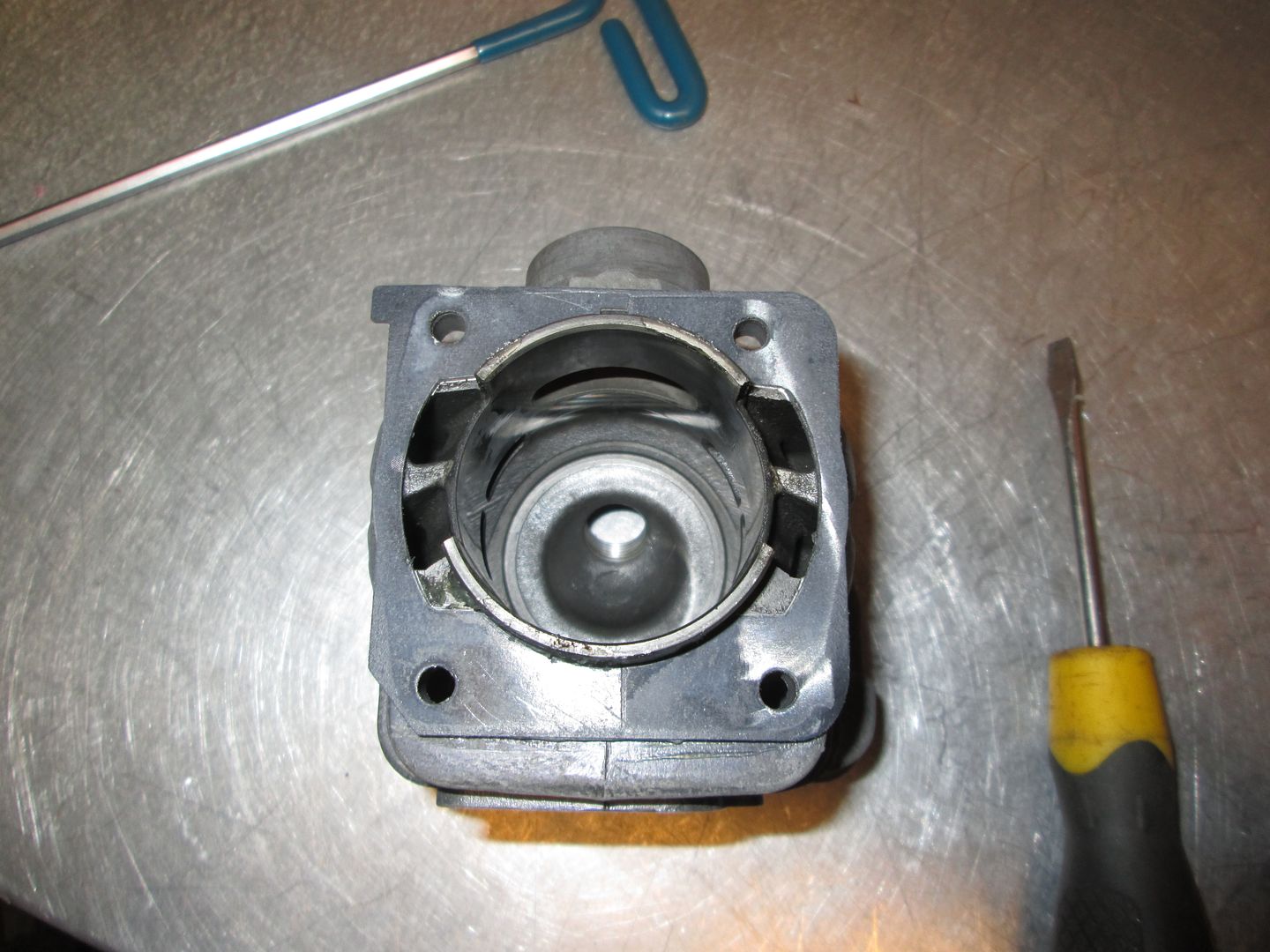

The first thing I wanted to do when I first started doing these saws was match the lower transfers to the case......as you can see they don't match at all.

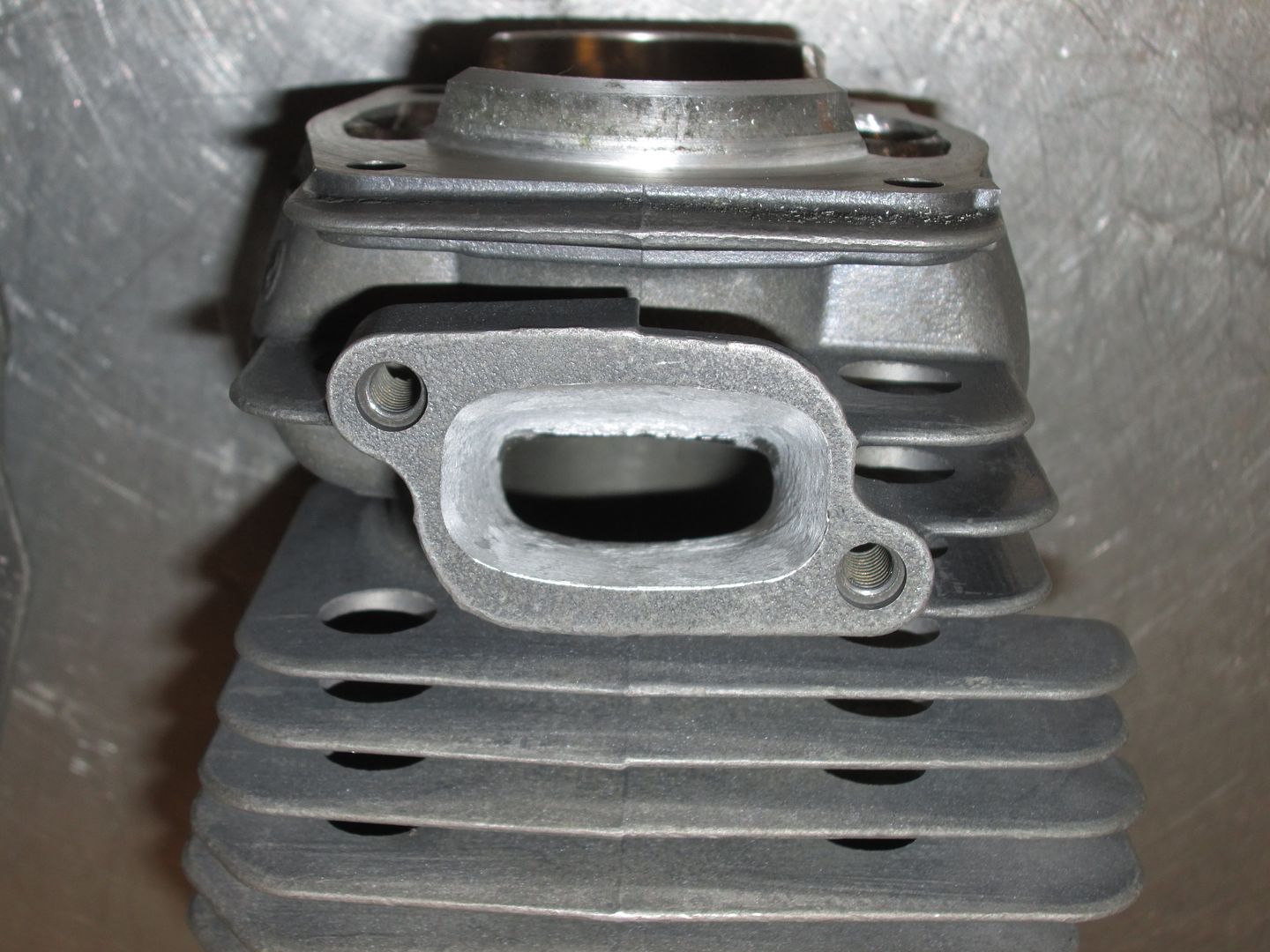

The base gasket does match the case so it can be used to mark the jug if you are so inclined....I do to give me something to go by.

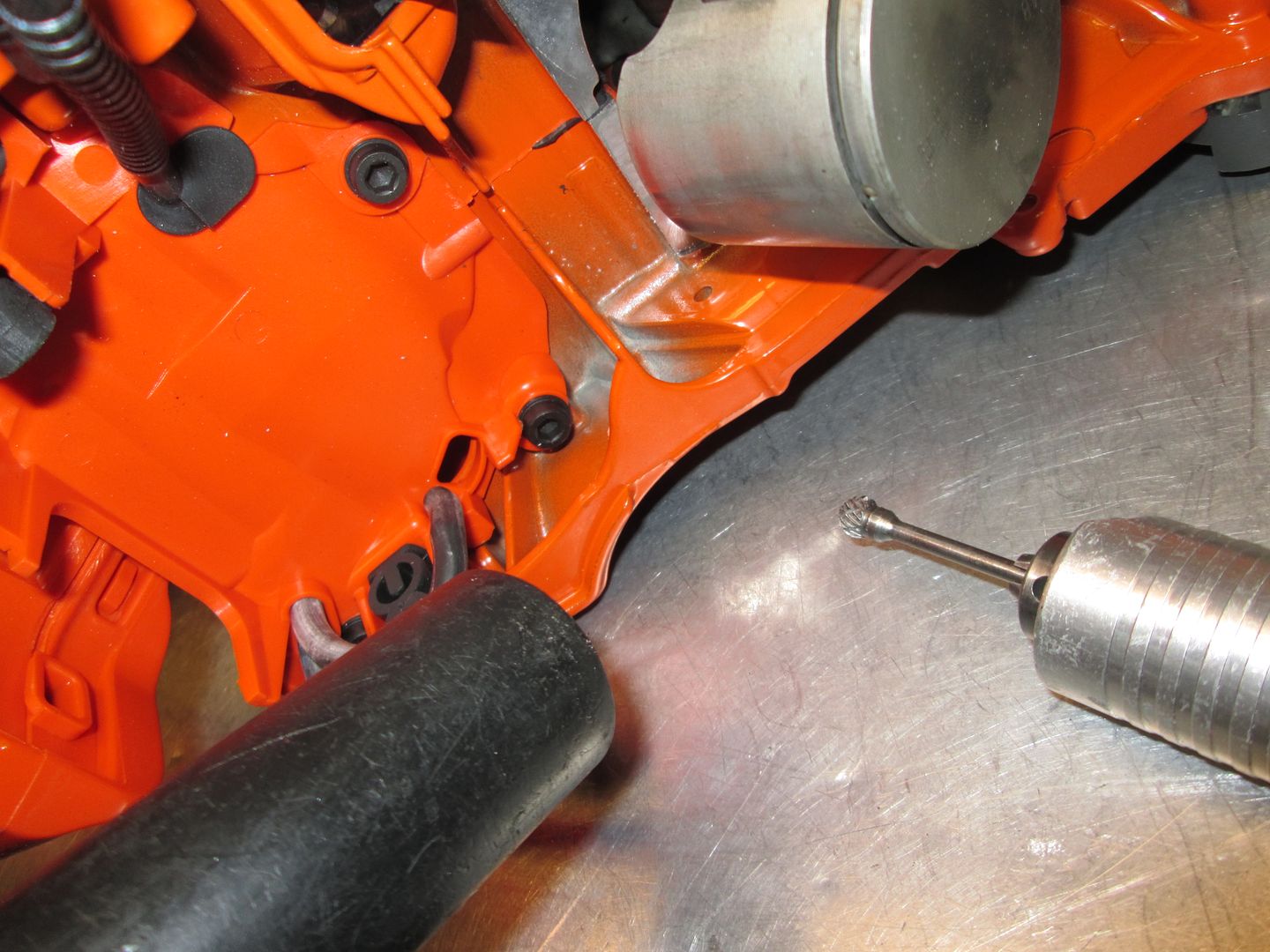

These days my mind isn't set on matching these two completely up......believe me when I say I've tried about every different way to do a 346XP. What I've found is that just a mild unshrouding and putting a radius on the entrances keeps the case volume tighter than opening them too much.....

The first thing I wanted to do when I first started doing these saws was match the lower transfers to the case......as you can see they don't match at all.

The base gasket does match the case so it can be used to mark the jug if you are so inclined....I do to give me something to go by.

These days my mind isn't set on matching these two completely up......believe me when I say I've tried about every different way to do a 346XP. What I've found is that just a mild unshrouding and putting a radius on the entrances keeps the case volume tighter than opening them too much.....

Last edited: