Local # 17 T.T.

ArboristSite Member

Can anyone tell me a link or the correct size files for the correct chain pitchs. Thanks....

Mike

Mike

Ok, I guess this brings me to my second question. Just by looking at the chain, how can you tell what brand/model it is? When you visually are picking the file, what are you looking for in relation to the cutter? What about depth gauge guides, do they all apply to the same chains? Thanks,Fish said:It depends on different brands/models of chain, as with Oregon, or other brands,

the model 33 .325 chain requires a different file than does the 20 LP .325 chain.

Also, as the chain gets filed back, the height of the cutter gets lower.

I personally visually pick the correct file for the chain in question, as the correct

file is critical.

With chain grinders, the top of the cutting angle is made by the side of the

cutting wheel, so there is only a couple of diameter wheels to worry about, the

correct diameter file is crucial for best performance in hand sharpening.

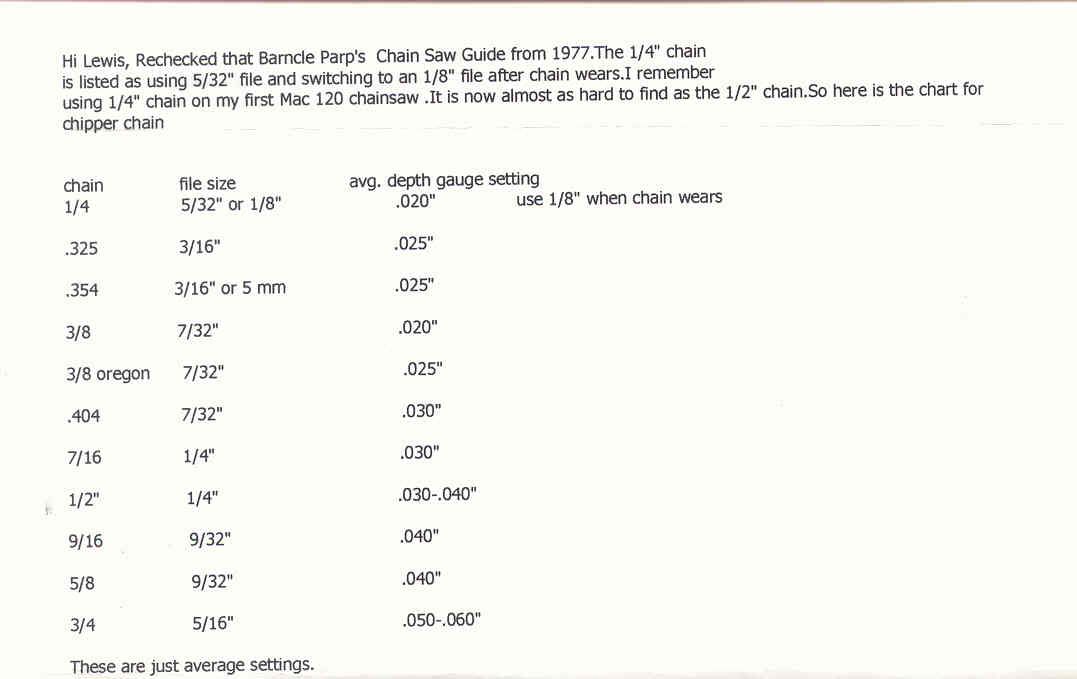

That is probably the closest you can get to a general rule, but as posted by others there are a lot of exceptions, among them the very usual 3/8" RM and RS chains from Stihl !Mike Maas said:5/32 for 3/8s LP

3/16 for .325

7/32 for 3/8

Mike Maas said:5/32 for 3/8s LP

3/16 for .325

7/32 for 3/8

If the file is too small, you'll get some left over gullet to file away. If it's too big, you start to cut into the top of the drive link and tie strap. Either way it's no biggy.

jokers said:Hi Mike,

I agree that filing a chain isn`t a "black art", but it`s not quite as simple as the quote implies.

First, if the file is too small you will have more excess material to file out of the gullet as Mike Maas states, but more importantly, you are more likely to impart too much sideplate angle or "hook" into your cutter making it grabby. Too much hook also produces a sharper topplate inside angle that is not as durable as a more blunt angle.

On the other hand, a file that is larger in diameter than optimal will produce a sideplate with not enough hook, no hook, or worse yet a back lean. This not only results in severely diminished cutting performance but also encourages the operator to push harder on the saw. This is a set up for equipment and personnel injury.

Russ

spacemule said:So, spark plugs never go bad, and size is irrelevant. Is this what you're arguing, Mike?

Enter your email address to join: