Hey guys. Lots of great info on home made tools and how to threads on splitting Stihl crankcases, but I couldn't find anything on splitting Husky cases.

Here's my issue......I just landed this clean old 181se that the guy said was a parts only saw. It needed a recoil and the gas line was rotted off, so I slapped on a spare recoil and it pulled 175 pounds compression!!... Then I replaced the fuel line and the thing fired up and runs awesome!!

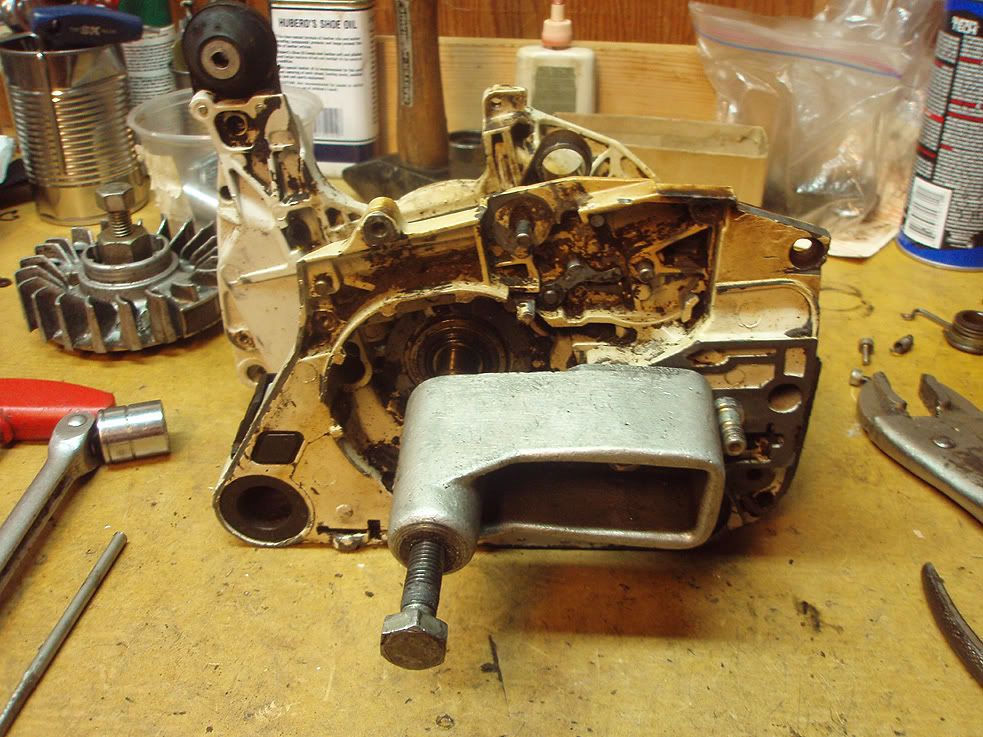

Next was when I found it's problem....I filled it with bar oil to check the oil pump and the crankcase is cracked two directions from the bar studs. I don't want to fool around JB welding the whole thing and I like these series of saws and want a gooder!!....Besides I have more crankcase, but not with good cranks that I can just do a simple top end swap......Has anyone split these cases with a smilar tool as the Stihls???......I'm not scared to tackle it and I can make almost any tool I need. I know the correct tool looks kinda like a valve spring compressor, but is it nessecary??

Here's the cracks.....One goes all the way around the front under the muffler and the other right behind the oil pump.:bang:

Here's my issue......I just landed this clean old 181se that the guy said was a parts only saw. It needed a recoil and the gas line was rotted off, so I slapped on a spare recoil and it pulled 175 pounds compression!!... Then I replaced the fuel line and the thing fired up and runs awesome!!

Next was when I found it's problem....I filled it with bar oil to check the oil pump and the crankcase is cracked two directions from the bar studs. I don't want to fool around JB welding the whole thing and I like these series of saws and want a gooder!!....Besides I have more crankcase, but not with good cranks that I can just do a simple top end swap......Has anyone split these cases with a smilar tool as the Stihls???......I'm not scared to tackle it and I can make almost any tool I need. I know the correct tool looks kinda like a valve spring compressor, but is it nessecary??

Here's the cracks.....One goes all the way around the front under the muffler and the other right behind the oil pump.:bang:

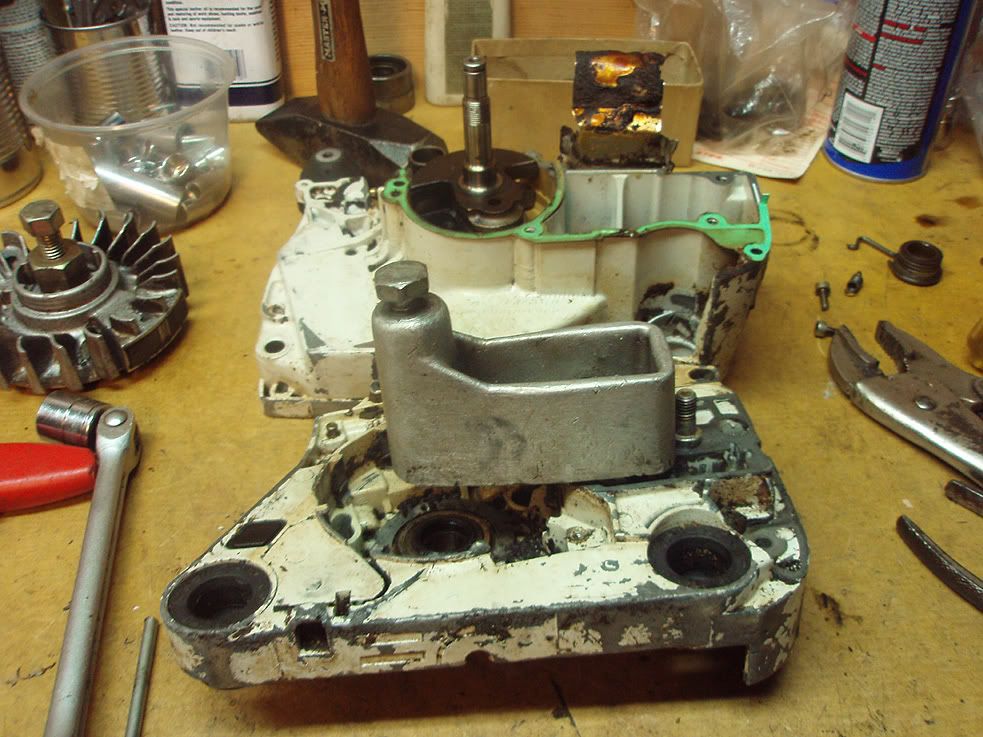

cap between them to protect threads. Came apart really easy, just be sure You keep an eye on where it is going to fall.

cap between them to protect threads. Came apart really easy, just be sure You keep an eye on where it is going to fall.