mtngun

Addicted to ArboristSite

My CSM has been gathering dust since January due to chores and work, but a neighbor wanted some trees gone, so the mill sprang into action today.

It's a Ponderosa Pine, 111 years old, 31" - 32", not including bark. The top blew off during the big windstorm of December 2006. The owner hoped the tree would survive, but it died this year.

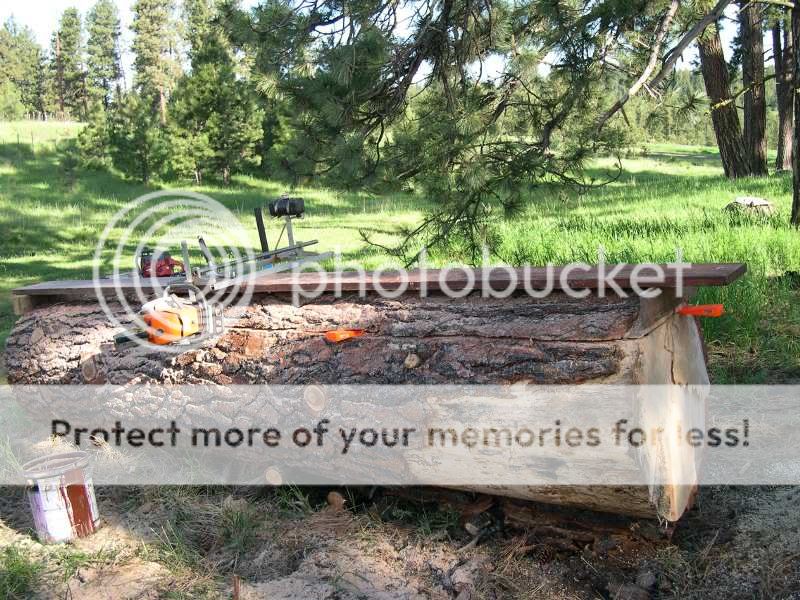

Cutting the first slab. My 36" bar can only cut about 29". and this sucker was about 34" including the bark, so it seemed like a good excuse to try quartersawing. I've never attempted quartersawing before, most of the trees I mill are too small to justify the effort. BTW, the bucket is used to collect the fine milling sawdust. The fine sawdust is handy for soaking up oil spills on the shop floor.

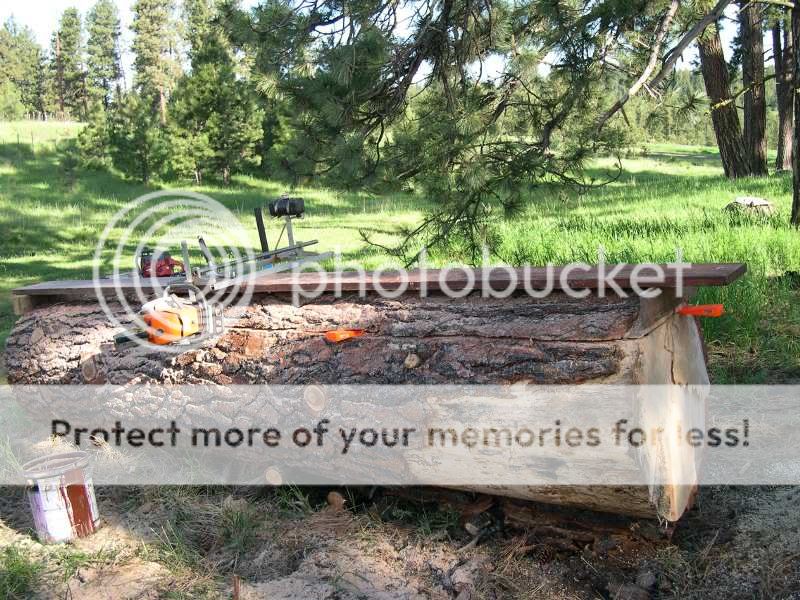

Slabbing the third side. To roll the 12 foot log into this position, I had to hook a come-along to the 60" logrite peavy. The logrite earned its keep today.

It was a blistering hot day by mountain standards (72 degrees F) and gasoline was boiling in the saw's tank. It made for balky starting sometimes. I ended up tuning the saw a little richer to help cool it down.

Then I split the cant down the center.

Split again into quarters. Almost every cut requires setup, so progress was slow, and still not a single board to show for the work.

End of day one. Boards and posts on the ladder rack, firewood slabs in the bed. Two more quarters to mill tomorrow.

Well, quartersawing with a CSM is very slow, especially to set up. However, once you have four square quarters, the setup is over, and the boards are cut quickly.

It's a Ponderosa Pine, 111 years old, 31" - 32", not including bark. The top blew off during the big windstorm of December 2006. The owner hoped the tree would survive, but it died this year.

Cutting the first slab. My 36" bar can only cut about 29". and this sucker was about 34" including the bark, so it seemed like a good excuse to try quartersawing. I've never attempted quartersawing before, most of the trees I mill are too small to justify the effort. BTW, the bucket is used to collect the fine milling sawdust. The fine sawdust is handy for soaking up oil spills on the shop floor.

Slabbing the third side. To roll the 12 foot log into this position, I had to hook a come-along to the 60" logrite peavy. The logrite earned its keep today.

It was a blistering hot day by mountain standards (72 degrees F) and gasoline was boiling in the saw's tank. It made for balky starting sometimes. I ended up tuning the saw a little richer to help cool it down.

Then I split the cant down the center.

Split again into quarters. Almost every cut requires setup, so progress was slow, and still not a single board to show for the work.

End of day one. Boards and posts on the ladder rack, firewood slabs in the bed. Two more quarters to mill tomorrow.

Well, quartersawing with a CSM is very slow, especially to set up. However, once you have four square quarters, the setup is over, and the boards are cut quickly.