I usually find the answers here by doing a search but couldn't get this one.

So I started porting my 051, the squish measured at 0.031 without gasket, so I milled the cylinder base down by 10mils. I am not doing anything to the transfers and just wanted to widen the exhaust port. This is the case where the sides of the skirt is very far away so I have to go by the 65% of the cylinder bore diameter.

The first question is, when 65% rule is used how is the port width defined? Is it straight line from one side of the port to the other or do I need to measure the arc and have the arc length be 65% of the bore?

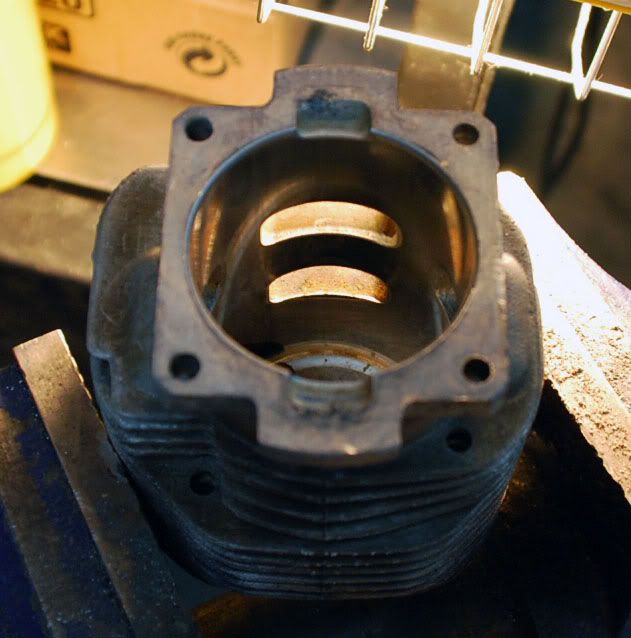

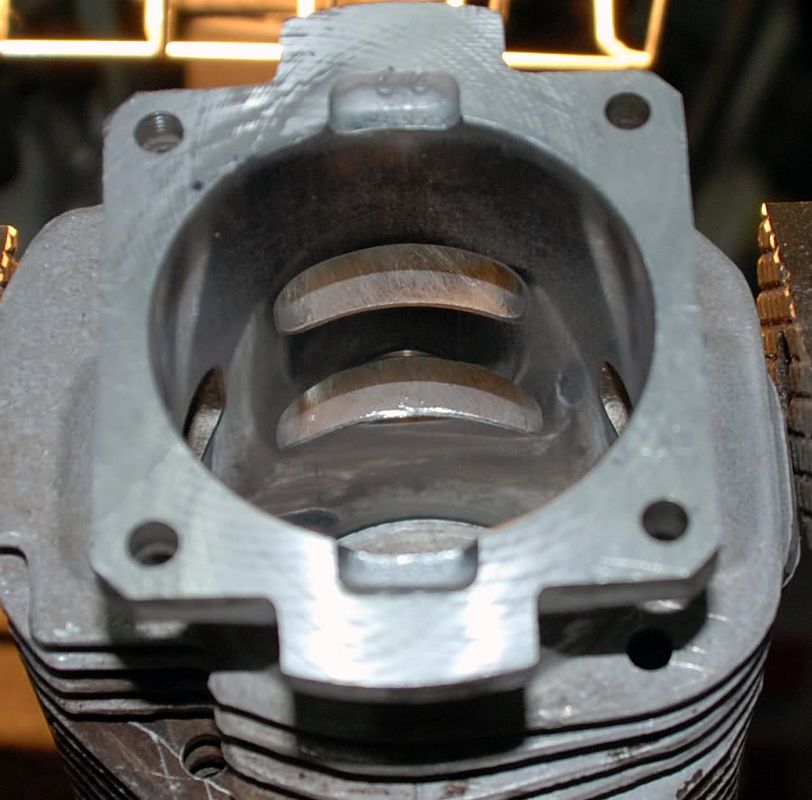

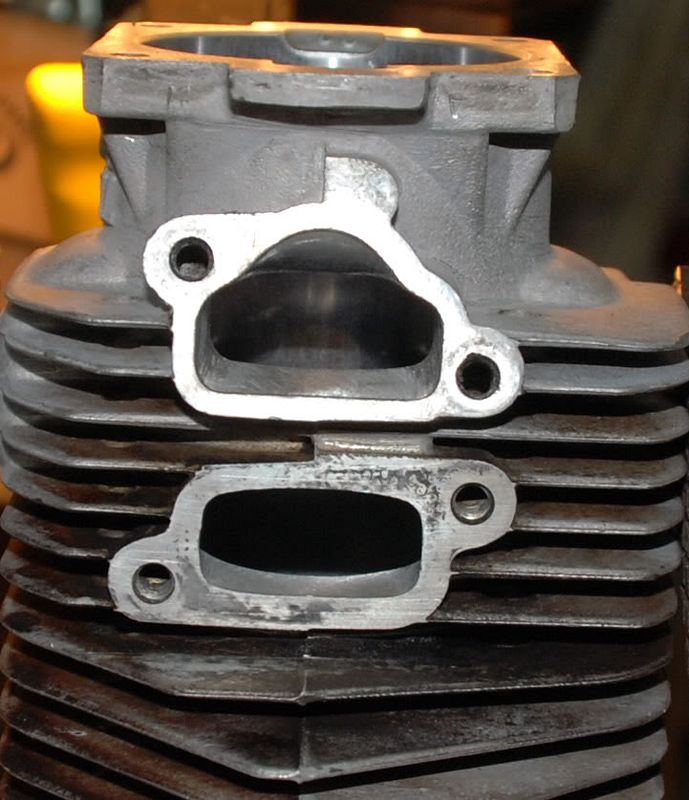

The second question I have has to do with piston at BDC. It does not completely clear the exhaust port (see picture 1). I don't think it is a big disadvantage because most of the flow happens at the top of the port, and it probably doesn't make sense taking off a section of the piston crown since that would significantly increase squish volume. I just wanted to get a confirmation on this.

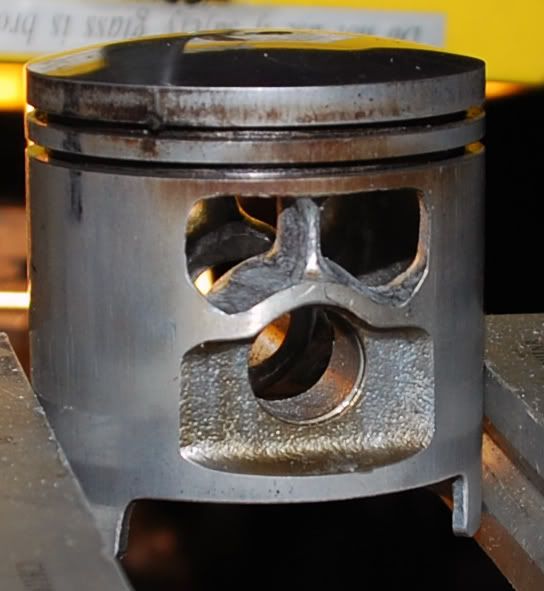

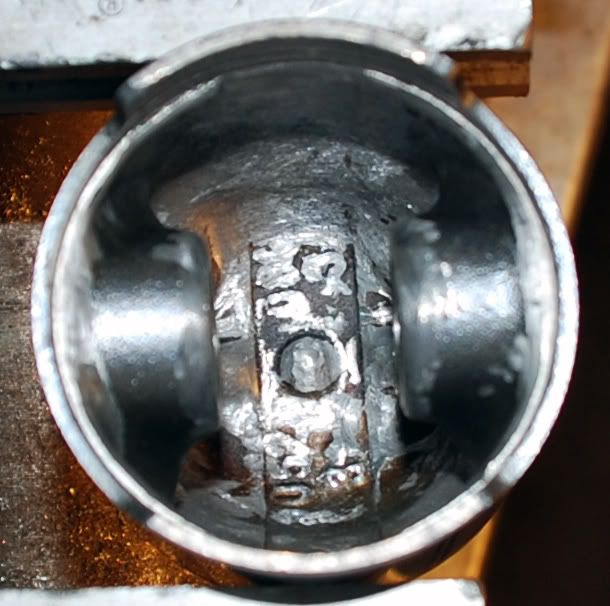

Third question/concern. Someone has messed with this saw and when I took the cylinder off I noticed that the piston was on backwards and the rings were worn out at the ends to the point that I picked that out visually, the cylinder however is flawless. The rings ends were not showing in the intake or exhaust ports but I should check the transfers. Other than that the piston looks symmetrical to me and I don't know if there is any concern with having it on backwards. I will check the transfers thou.

So I started porting my 051, the squish measured at 0.031 without gasket, so I milled the cylinder base down by 10mils. I am not doing anything to the transfers and just wanted to widen the exhaust port. This is the case where the sides of the skirt is very far away so I have to go by the 65% of the cylinder bore diameter.

The first question is, when 65% rule is used how is the port width defined? Is it straight line from one side of the port to the other or do I need to measure the arc and have the arc length be 65% of the bore?

The second question I have has to do with piston at BDC. It does not completely clear the exhaust port (see picture 1). I don't think it is a big disadvantage because most of the flow happens at the top of the port, and it probably doesn't make sense taking off a section of the piston crown since that would significantly increase squish volume. I just wanted to get a confirmation on this.

Third question/concern. Someone has messed with this saw and when I took the cylinder off I noticed that the piston was on backwards and the rings were worn out at the ends to the point that I picked that out visually, the cylinder however is flawless. The rings ends were not showing in the intake or exhaust ports but I should check the transfers. Other than that the piston looks symmetrical to me and I don't know if there is any concern with having it on backwards. I will check the transfers thou.