Curlycherry1

Addicted to ArboristSite

Well I have hinted that I have been around a while and so I dug out some old photos and can now put together an old-timey picture show of my family's days in the firewood business. So go get some coffee and settle in and here we go.

About 1958-59 my dad would get the big sugar maple logs too big for anyone else to deal with from the town of Liverpool, NY. The town would drop them off at my grandmother's house on Tamarack street and every weekend we would buzz away on those with Homelite XL12s. We would haul the pieces home and I, my brother and my neighbors would all split the wood by hand to earn money. We would pile it for a few bucks more. It was hard work but for kids the pay was good the pile was always there for us to chop if we wanted some money.

In 1970 or 71 dad had our first woodsplitter built. It was compact and it was solid as a rock. I used it through the 1970s and literally put several thousand face cords of wood through it. It had about a 5-6 second cycle and it would not stop for anything. Several times I tore the steel wedge in half like tearing a piece of paper. The welds were that good. Here is a picture of me giving the splitter a coat of paint from a rattle can in I think 1971. Check out how short the return hose is for the cylinder. The hose company that made that up for us said it would never work and that it would break. It was about the only hose that did not break in the 12+ years that I used that splitter. Notice how compact it is. There is no extra resivoir for the oil because the welder boxed in the beam under the ram so that is where the oil could go. There was no wasted space on that splitter. The pump was also a very efficient 2-stage pump that cost me a fortune, but it held up well and only had to be rebuilt once. the ram never developed a leak, ever. We broke some hoses but that was about it.

About 1972 the guy that built the woodsplitter for us owned 40 acres of land located at the end of our road. I was 11 at the time and he had a forester mark the cull trees for removal. He let me go in and chop out the culls which consisted of mostly big old maples that were no good for lumber. So for the next 4-5 years I would go in on snowmobile in the winter and drop and block the wood. In the summer I would take my Ford 9N and drive up to the wood lot and bring the wood home. I bought the tractor for $1100 when I was 11 so I could tend to my garden and to use it to move firewood. Here is that tractor in use with me on it pulling out a trailer load of blocked wood.

In 1977 I got my driver's liscence just as the woods at the end of my road was done. I advertised in the Pennysaver for a new contract and I landed one up in Cleveland, NY on the Vandercamp kid's camp. The 1100 acre camp on a private lake had been managed for over 60 years for lumber. The forester in charge of the camp thought I was nuts to be a 16 year old kid going to cut firewood commercially. Dad signed the contract and paid my money and the forester gave me 4 acres of monster 4-5' sugar maples lining and old dirt road on the property. Little did he know I would thrive on those things because I could drop them across the road and back my Dad's 1956 Ford F500 stake rack right up to the wood. I got all that wood out in about 6-7 months and he gave me a much bigger contract. Here is one of the oaks I cut that property. They gave me old fence rows and old fallow pastures to cut. It was not ideal, but I could make good money using my tractor to get access to all that wood.

In the sping of 1978 the forester at the camp had left to go to Guam and a new guy was in place. I had cut wood all winter on one large tract of land and come spring when I went to go fetch it the whole thing was gone. Well over a couple of hundred cords of wood was gone! The forester seemed to know something but he would not admit it. Again I advertised in the Pennsaver and I found a woods to work in located North of Fulton, NY. This was swampy land, but closer to home and the wood was free as long as I gave the landowner 15-20 face cords to burn for himself. I bought a Farmi skidding winch and I changed how I worked by moving the logs to central locations on the land, blocking it up, and then trailering it out.

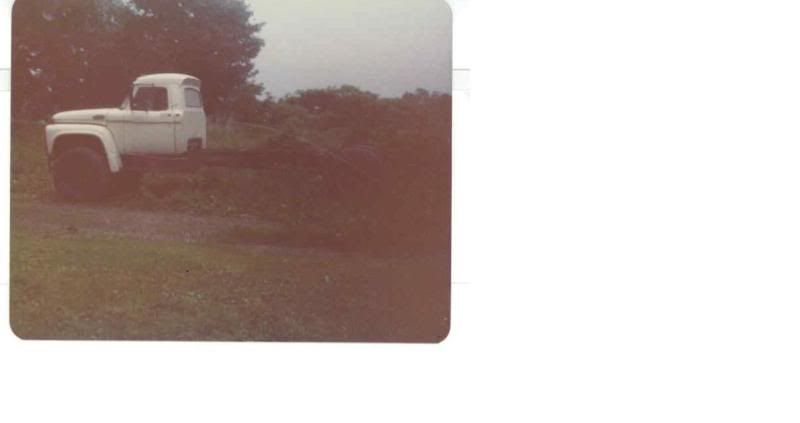

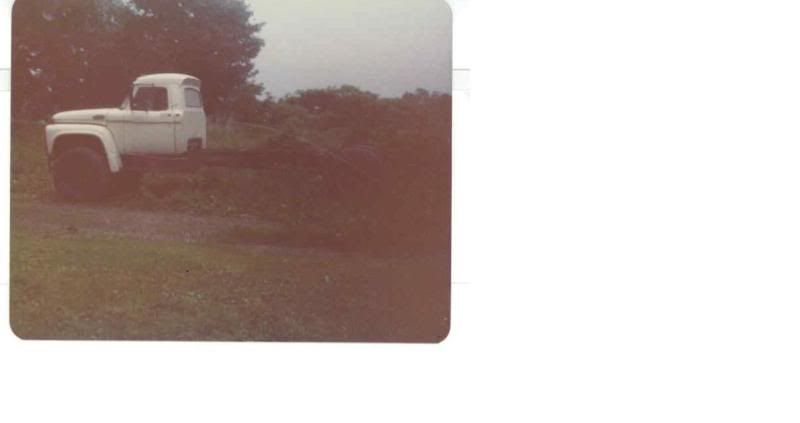

I was getting more efficient and my dad's of '56 Ford was showing signs of wear and tear. I found a nice 1968 F800 with the frame, axel, tranny, engine that I needed and it was only $2500. I bought it and held it for a year before putting a dump rack on it. I wanted a truck that could hold 10 face cords comfortably with space to spare on the back end so the cops would not hassle me forweight restrictions. Here is the truck with no rack.

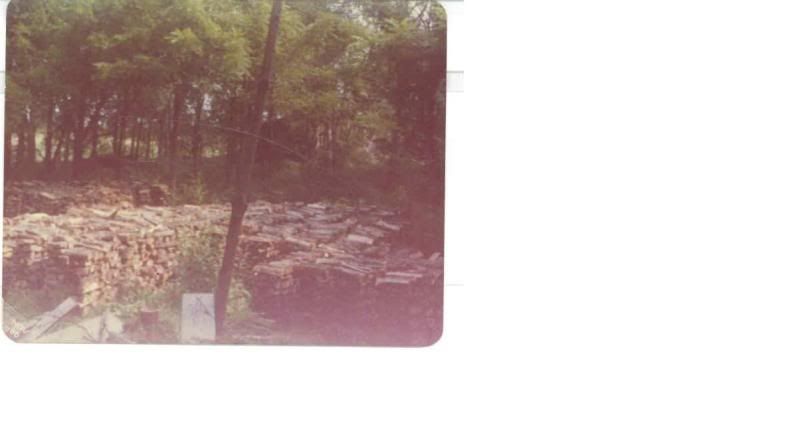

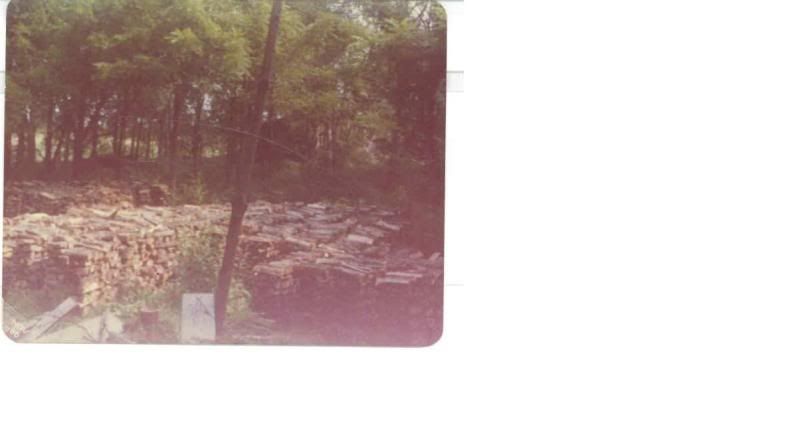

1979 Came along and my parents got divorced. Because my dad was doing the delivering of much of my wood for me my mom booted my firewood operation off her land. Dad bought a 25 acre farm at the other end of the road my mom lived on and I moved my wood splitting and drying to that location. It was a bad location due to lots of walnut trees on the property and little big open space. So I had to tuck wood in all kinds of areas around the property. It was hard to get 500-700 face cords of wood spread out on that land so it could be gotten in the fall when the area was wet and muddy.

Here are picks of some of my firewood piled up on that land.

In 1981 I was in college and ready to get more efficient. I was delivering wood to customers in the summer in 10 face cord loads so I needed the big truck up and going. I had Fruehauf put a 16'stake rack on it with power up and power down dump. 4' high plywood sides with 5-5" stakes for holding the sides. That way I could load without catching my neck on the cross chains. Here is the truck on its maiden dumping voyage.

Bonus points to anyone that can identify the specific red and blue on the dump bed.

I entered grad school in 1984 and my brother took over the business. He did not like going to the woods so he bought logs and bucked them up for a few years,but as he grew he could not keep up with production so he got a Timberwolf processor. He now has a very big operation and he has it on my mom's land again. She let him have it there after my dad died in 1993, and she died in 2005 and my brother inherited the land. It is a big operation now and I won't comment on how much wood he sells, because he got sued by his developer neighbor who had big plans to develop the land next to him and put up houses. They wanted his business gone because they considered it an eye sore. So he cannot get any bigger but he was limited by delivery time when the suit came along anyway. The town grandfathered my brother's business and told the neighbor to take a hike. The land sits undeveloped.

I am limited to 8 photos in a post so I will skip posting a shot of my borther's operation taken from Google Earth.

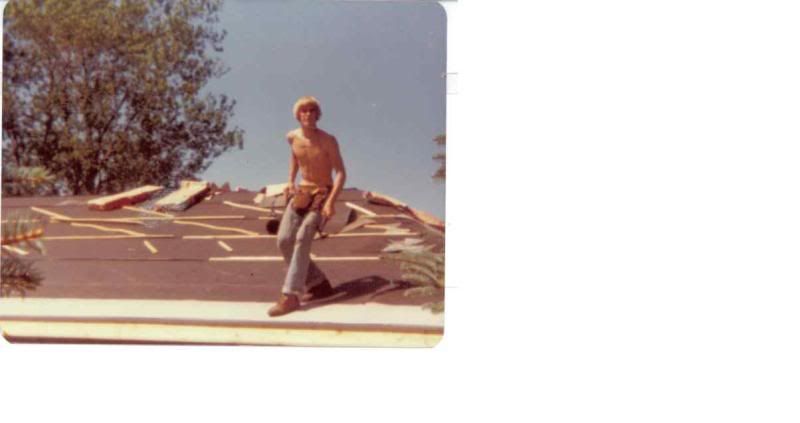

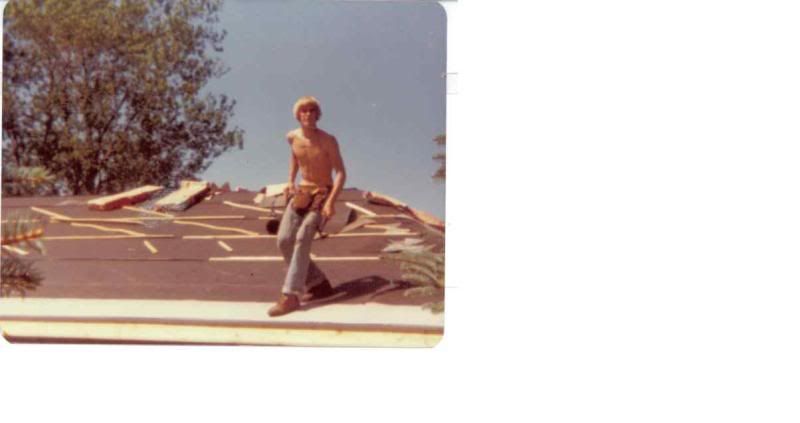

So that is it, my history in the firewood business. I am out of it now and in many ways I do not miss it. It is fun on a small scale,but it is rough on the body. Here is a shot of me from the late 1970s and you can see I had zero body fat on me. I could drink 24 bottles of Pepsi per day, eat a dozen doughnuts and eat two whopper hamburgers and still feel hungry. Doing roofing/construction and then hustling firewood every spare moment can make a person tough as nails.

Dabadabadaba that's all folks! Hope you enjoy.

About 1958-59 my dad would get the big sugar maple logs too big for anyone else to deal with from the town of Liverpool, NY. The town would drop them off at my grandmother's house on Tamarack street and every weekend we would buzz away on those with Homelite XL12s. We would haul the pieces home and I, my brother and my neighbors would all split the wood by hand to earn money. We would pile it for a few bucks more. It was hard work but for kids the pay was good the pile was always there for us to chop if we wanted some money.

In 1970 or 71 dad had our first woodsplitter built. It was compact and it was solid as a rock. I used it through the 1970s and literally put several thousand face cords of wood through it. It had about a 5-6 second cycle and it would not stop for anything. Several times I tore the steel wedge in half like tearing a piece of paper. The welds were that good. Here is a picture of me giving the splitter a coat of paint from a rattle can in I think 1971. Check out how short the return hose is for the cylinder. The hose company that made that up for us said it would never work and that it would break. It was about the only hose that did not break in the 12+ years that I used that splitter. Notice how compact it is. There is no extra resivoir for the oil because the welder boxed in the beam under the ram so that is where the oil could go. There was no wasted space on that splitter. The pump was also a very efficient 2-stage pump that cost me a fortune, but it held up well and only had to be rebuilt once. the ram never developed a leak, ever. We broke some hoses but that was about it.

About 1972 the guy that built the woodsplitter for us owned 40 acres of land located at the end of our road. I was 11 at the time and he had a forester mark the cull trees for removal. He let me go in and chop out the culls which consisted of mostly big old maples that were no good for lumber. So for the next 4-5 years I would go in on snowmobile in the winter and drop and block the wood. In the summer I would take my Ford 9N and drive up to the wood lot and bring the wood home. I bought the tractor for $1100 when I was 11 so I could tend to my garden and to use it to move firewood. Here is that tractor in use with me on it pulling out a trailer load of blocked wood.

In 1977 I got my driver's liscence just as the woods at the end of my road was done. I advertised in the Pennysaver for a new contract and I landed one up in Cleveland, NY on the Vandercamp kid's camp. The 1100 acre camp on a private lake had been managed for over 60 years for lumber. The forester in charge of the camp thought I was nuts to be a 16 year old kid going to cut firewood commercially. Dad signed the contract and paid my money and the forester gave me 4 acres of monster 4-5' sugar maples lining and old dirt road on the property. Little did he know I would thrive on those things because I could drop them across the road and back my Dad's 1956 Ford F500 stake rack right up to the wood. I got all that wood out in about 6-7 months and he gave me a much bigger contract. Here is one of the oaks I cut that property. They gave me old fence rows and old fallow pastures to cut. It was not ideal, but I could make good money using my tractor to get access to all that wood.

In the sping of 1978 the forester at the camp had left to go to Guam and a new guy was in place. I had cut wood all winter on one large tract of land and come spring when I went to go fetch it the whole thing was gone. Well over a couple of hundred cords of wood was gone! The forester seemed to know something but he would not admit it. Again I advertised in the Pennsaver and I found a woods to work in located North of Fulton, NY. This was swampy land, but closer to home and the wood was free as long as I gave the landowner 15-20 face cords to burn for himself. I bought a Farmi skidding winch and I changed how I worked by moving the logs to central locations on the land, blocking it up, and then trailering it out.

I was getting more efficient and my dad's of '56 Ford was showing signs of wear and tear. I found a nice 1968 F800 with the frame, axel, tranny, engine that I needed and it was only $2500. I bought it and held it for a year before putting a dump rack on it. I wanted a truck that could hold 10 face cords comfortably with space to spare on the back end so the cops would not hassle me forweight restrictions. Here is the truck with no rack.

1979 Came along and my parents got divorced. Because my dad was doing the delivering of much of my wood for me my mom booted my firewood operation off her land. Dad bought a 25 acre farm at the other end of the road my mom lived on and I moved my wood splitting and drying to that location. It was a bad location due to lots of walnut trees on the property and little big open space. So I had to tuck wood in all kinds of areas around the property. It was hard to get 500-700 face cords of wood spread out on that land so it could be gotten in the fall when the area was wet and muddy.

Here are picks of some of my firewood piled up on that land.

In 1981 I was in college and ready to get more efficient. I was delivering wood to customers in the summer in 10 face cord loads so I needed the big truck up and going. I had Fruehauf put a 16'stake rack on it with power up and power down dump. 4' high plywood sides with 5-5" stakes for holding the sides. That way I could load without catching my neck on the cross chains. Here is the truck on its maiden dumping voyage.

Bonus points to anyone that can identify the specific red and blue on the dump bed.

I entered grad school in 1984 and my brother took over the business. He did not like going to the woods so he bought logs and bucked them up for a few years,but as he grew he could not keep up with production so he got a Timberwolf processor. He now has a very big operation and he has it on my mom's land again. She let him have it there after my dad died in 1993, and she died in 2005 and my brother inherited the land. It is a big operation now and I won't comment on how much wood he sells, because he got sued by his developer neighbor who had big plans to develop the land next to him and put up houses. They wanted his business gone because they considered it an eye sore. So he cannot get any bigger but he was limited by delivery time when the suit came along anyway. The town grandfathered my brother's business and told the neighbor to take a hike. The land sits undeveloped.

I am limited to 8 photos in a post so I will skip posting a shot of my borther's operation taken from Google Earth.

So that is it, my history in the firewood business. I am out of it now and in many ways I do not miss it. It is fun on a small scale,but it is rough on the body. Here is a shot of me from the late 1970s and you can see I had zero body fat on me. I could drink 24 bottles of Pepsi per day, eat a dozen doughnuts and eat two whopper hamburgers and still feel hungry. Doing roofing/construction and then hustling firewood every spare moment can make a person tough as nails.

Dabadabadaba that's all folks! Hope you enjoy.