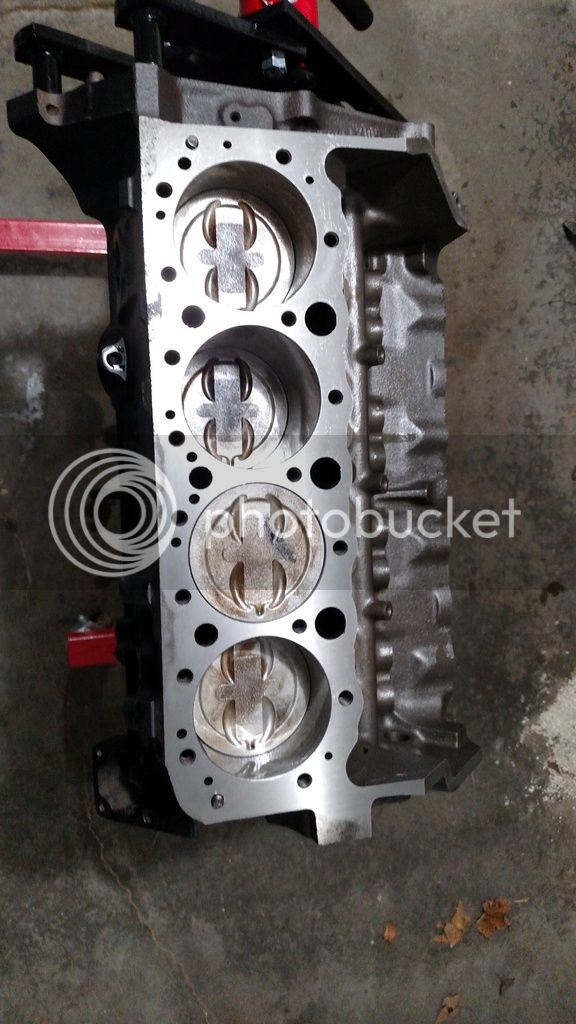

So my weekend truck and firewood hauler is a '84 K10 and it had a small he's gasket leak at the end of last year. Long story short I thought I would take on rebuilding the engine. First I thought I would just freshen up the heads and replace the gaskets. That turned into changing cams which snow balled into pullin the entire engine deglazing the cylinders new bearings yada yada yada. Well I'm currently breaking down the rotating assembly so the block and crank can go to the machinist take a bath and get mic'ed up and the first couple of rod end bearings that came out look like this.

I'd say it was a good choice to tear into this bottom end. However, every action has an equal and opposite reaction and now I think there's a good chance the machinist is going to want to clean up the crank journals and possibly bore the block. So now I'm at a decision point, put the money and work into this old mid 70's flat tappet cam block or go yank a roller block at the junk yard to put the money into. Since I'm going to use vortec heads in my build I think now is a perfect time to make the move and build a roller motor.

I'd say it was a good choice to tear into this bottom end. However, every action has an equal and opposite reaction and now I think there's a good chance the machinist is going to want to clean up the crank journals and possibly bore the block. So now I'm at a decision point, put the money and work into this old mid 70's flat tappet cam block or go yank a roller block at the junk yard to put the money into. Since I'm going to use vortec heads in my build I think now is a perfect time to make the move and build a roller motor.