outofstepper

ArboristSite Lurker

So now that I've got a small CSM built, its time to start doing damage.

My intention so far is to just start slabbing. Pick a log that'll fit in my

mill and just start slabbing my way through to the bottom.

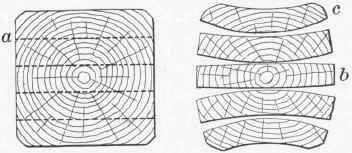

Thing is, I'm not sure this is the best way to do it. Meaning, will I get

the "best boards" this way?

Plan is to square them up once they're dry.. on a table saw.. so I'm not

worried about final dimensions just yet.

But I don't know enough about wood to know what the "choice cuts" are.

If I cut a 1.5" x 15" board out of the center, including the pith, will it be

any good?

Does just cutting slabs waste wood? should I be turning and flipping the

log? Should I split it two?

Maybe the answers to all these questions are "it depends" -- but if anyone

can shed some light on things to avoid, I'd appreciate it.

The end goal is nice clean strong boards for wood working.

Thanks!

My intention so far is to just start slabbing. Pick a log that'll fit in my

mill and just start slabbing my way through to the bottom.

Thing is, I'm not sure this is the best way to do it. Meaning, will I get

the "best boards" this way?

Plan is to square them up once they're dry.. on a table saw.. so I'm not

worried about final dimensions just yet.

But I don't know enough about wood to know what the "choice cuts" are.

If I cut a 1.5" x 15" board out of the center, including the pith, will it be

any good?

Does just cutting slabs waste wood? should I be turning and flipping the

log? Should I split it two?

Maybe the answers to all these questions are "it depends" -- but if anyone

can shed some light on things to avoid, I'd appreciate it.

The end goal is nice clean strong boards for wood working.

Thanks!