Decided it was time to a medium size chipper to smaller jobs around the farms. We need something that will chip up the smaller limbs as we cut and use most everything over 2 inches in diameter. When we clean fencerows and such we'll burn those. When a single tree or large branch falls in a field it will be a lot nicer to chip it and blow it in the fencerow where a bush hog will spread it out. A plus will also be with other cleanups I can simply blow in the back of a truck to save hours of limb dragging or multible brush loads with the truck.

I wanted a PTO powered version with a power infeed system. Did some comparing of different ones and decided on a WoodMaxx WM- 8H. It will handle up to 8 inch material, which is more than I need but it's nice to have the option! Should be a strong unit that will last. Here is a review and how it is working for us.

I had planned on doing a step by step on the set up but the pics got messed up and I lost those. The manufacturer has a set up video you can view on YouTube if you want to get an idea. One thing I will stress is to COMPLETELY go over the unit and TIGHTEN ALL BOLTS. some were not tight , even on the pumps so do yourself a favor and take the time. An old trick is to get a dry erase marker and mark them as you go so you can be sure you didn't miss any.

It has a self contained hydraulic system so you have no hookups. Just hook the unit up and PTO and that is it. Dual hydraulic motors on the feed rollers and they are variable speed if you have a smaller tractor and run bigger diameter stuff.

Greasable bearings and access panels to get to the knives make it nice. Overall the quality of the machine is better than I expected.

Chip chute is completely adjustable and lockable. Has a flap on the top to direct chips too which is nice. You do have to get pretty close if your using a trailer but I've completely filled a 10 ' x 12' x 3' trailer with it and it wasn't a big deal. You could put an extension on the chute without too much work but the extra weight may work on the welds here.

This is the forward and reverse lever. I took off the bar that is supposed to be on the top of the feed chute. When the unit would bounce a little it would shut the feed roller off. I'm sure it is a safety feature but I'll take responsibility for my actions. It's easily reachable for panic stops this way for me still. It could use a little better design as it's too much weight for the valve body to hold.

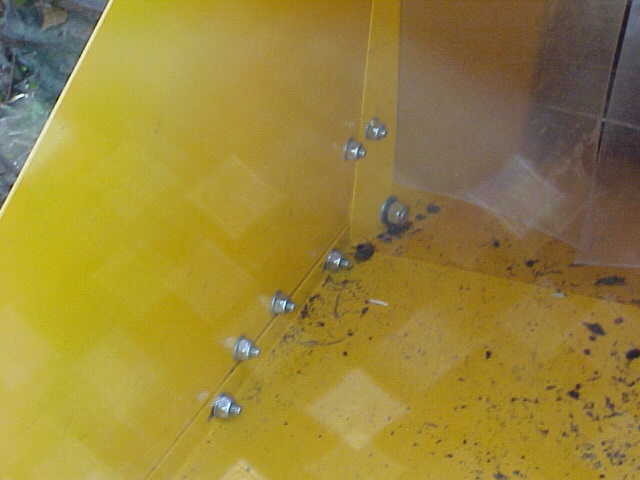

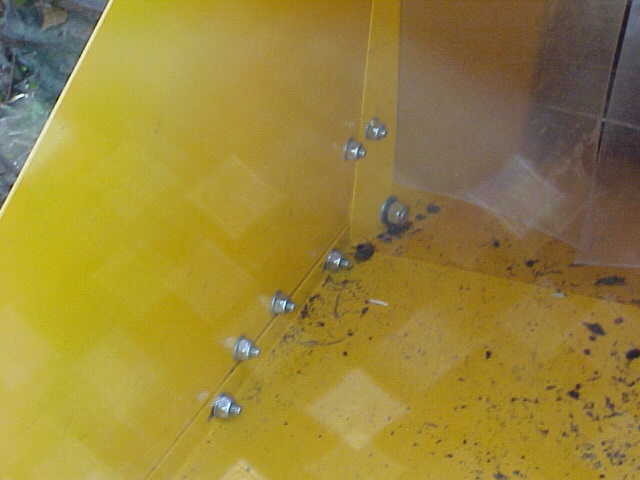

This is something I'm going to change. I assembled according to manufacture and they showed nuts in with standard bolts. Stuff does snag up some as they have a lot of extra thread sticking out. I'm sure it's another safety thing as to not snag yourself on the outside of the macione. I'm going to pick up some short carriage bolts and have the heads in.

This is where the feed roller pivots. After running it for a few hours I noticed the roller casting was rubbing on the radiused slot. It wore into the casting some and found that the adjustment was WAY off. Don't know why they missed that but is fine now. Don't take things for granted and COMPLETELY check it over before running.

Trying to show the wear on the casting here.

3 point hook up is adjustable and I didn't even have to cut the drive shaft for my application. They have all the specs in the manual with easy to follow instructions.

Air intake to keep the chips flying a plug free. Haven't had a plug yet.

I wanted a PTO powered version with a power infeed system. Did some comparing of different ones and decided on a WoodMaxx WM- 8H. It will handle up to 8 inch material, which is more than I need but it's nice to have the option! Should be a strong unit that will last. Here is a review and how it is working for us.

I had planned on doing a step by step on the set up but the pics got messed up and I lost those. The manufacturer has a set up video you can view on YouTube if you want to get an idea. One thing I will stress is to COMPLETELY go over the unit and TIGHTEN ALL BOLTS. some were not tight , even on the pumps so do yourself a favor and take the time. An old trick is to get a dry erase marker and mark them as you go so you can be sure you didn't miss any.

It has a self contained hydraulic system so you have no hookups. Just hook the unit up and PTO and that is it. Dual hydraulic motors on the feed rollers and they are variable speed if you have a smaller tractor and run bigger diameter stuff.

Greasable bearings and access panels to get to the knives make it nice. Overall the quality of the machine is better than I expected.

Chip chute is completely adjustable and lockable. Has a flap on the top to direct chips too which is nice. You do have to get pretty close if your using a trailer but I've completely filled a 10 ' x 12' x 3' trailer with it and it wasn't a big deal. You could put an extension on the chute without too much work but the extra weight may work on the welds here.

This is the forward and reverse lever. I took off the bar that is supposed to be on the top of the feed chute. When the unit would bounce a little it would shut the feed roller off. I'm sure it is a safety feature but I'll take responsibility for my actions. It's easily reachable for panic stops this way for me still. It could use a little better design as it's too much weight for the valve body to hold.

This is something I'm going to change. I assembled according to manufacture and they showed nuts in with standard bolts. Stuff does snag up some as they have a lot of extra thread sticking out. I'm sure it's another safety thing as to not snag yourself on the outside of the macione. I'm going to pick up some short carriage bolts and have the heads in.

This is where the feed roller pivots. After running it for a few hours I noticed the roller casting was rubbing on the radiused slot. It wore into the casting some and found that the adjustment was WAY off. Don't know why they missed that but is fine now. Don't take things for granted and COMPLETELY check it over before running.

Trying to show the wear on the casting here.

3 point hook up is adjustable and I didn't even have to cut the drive shaft for my application. They have all the specs in the manual with easy to follow instructions.

Air intake to keep the chips flying a plug free. Haven't had a plug yet.