flashhole

Addicted to ArboristSite

Haddon Lumbermakers retail for 79.95. I picked up one new-in-the-box delivered to my door for $28. I paid too much. Without going into a rant I will just list the specific flaws that warrant attention for anyone considering buying one. This is simply one man's opinion.

It's too small. I've been using it with a Homelite X2 saw and that is as big a saw as I feel comfortable using on this device. I fitted it to my Stihl 041 and quickly decided that was a very bad idea. I've been milling 2" thick slabs but need to go to 4" soon and need a bit more saw to handle the bigger slabs.

It's frail. A milling tool will be subject to a fair amount of stress. This device flexes during use. Not a good thing.

The claim of it fitting a standard 2"x6" is false. You need to cut a custom guide from a 2"x8" if you want a tight rail guide to avoid sloppy cuts.

The guide rail mechanism is too short. The tool does not aid stability in the cut. It should be at least 12" long and provide a balance point over the bar mount.

The 3-screw bar clamp mechanism is a bad joke. The first time you use this tool you quickly learn the benefit of drilling a bar and bolting the tool to the bar to avoid it vibrating loose causing a lot of down time from milling.

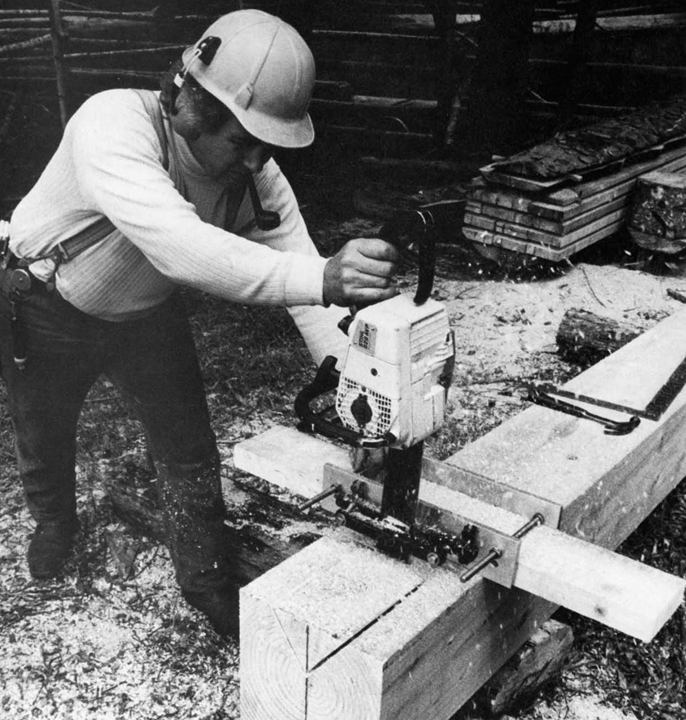

If you are considering this type of tool I strongly recommend you go a different route. Something like the device pictured below (page 158 Chainsaw Milling ) will give you much better control and stability in the cut.

I will keep my tool until I make a replacement.

Things I like about the design. When cutting lumber. I size the slabs to a specific guide. For example: a 2"x4" guide board can be used on both sides to cut consistent lumber without having to move the guide. Cut down one side, flip it around and cut down the other side. Works well with a 2"x4" guide board and a 2"x6" guide board. If you want bigger you have to realign the guide for individual cuts. That's a pain in the arse.

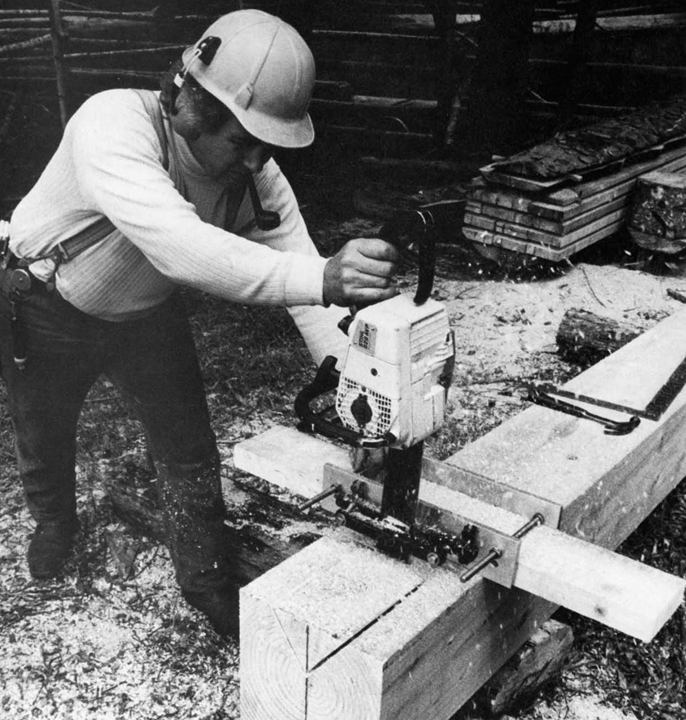

An adjustable width device like the one shown below is infinitely more flexible to use with standard lumber as guide boards where you can flip and cut both sides of the slab. I'm going to make one like this for my own use.

It's too small. I've been using it with a Homelite X2 saw and that is as big a saw as I feel comfortable using on this device. I fitted it to my Stihl 041 and quickly decided that was a very bad idea. I've been milling 2" thick slabs but need to go to 4" soon and need a bit more saw to handle the bigger slabs.

It's frail. A milling tool will be subject to a fair amount of stress. This device flexes during use. Not a good thing.

The claim of it fitting a standard 2"x6" is false. You need to cut a custom guide from a 2"x8" if you want a tight rail guide to avoid sloppy cuts.

The guide rail mechanism is too short. The tool does not aid stability in the cut. It should be at least 12" long and provide a balance point over the bar mount.

The 3-screw bar clamp mechanism is a bad joke. The first time you use this tool you quickly learn the benefit of drilling a bar and bolting the tool to the bar to avoid it vibrating loose causing a lot of down time from milling.

If you are considering this type of tool I strongly recommend you go a different route. Something like the device pictured below (page 158 Chainsaw Milling ) will give you much better control and stability in the cut.

I will keep my tool until I make a replacement.

Things I like about the design. When cutting lumber. I size the slabs to a specific guide. For example: a 2"x4" guide board can be used on both sides to cut consistent lumber without having to move the guide. Cut down one side, flip it around and cut down the other side. Works well with a 2"x4" guide board and a 2"x6" guide board. If you want bigger you have to realign the guide for individual cuts. That's a pain in the arse.

An adjustable width device like the one shown below is infinitely more flexible to use with standard lumber as guide boards where you can flip and cut both sides of the slab. I'm going to make one like this for my own use.