1hander

ArboristSite Operative

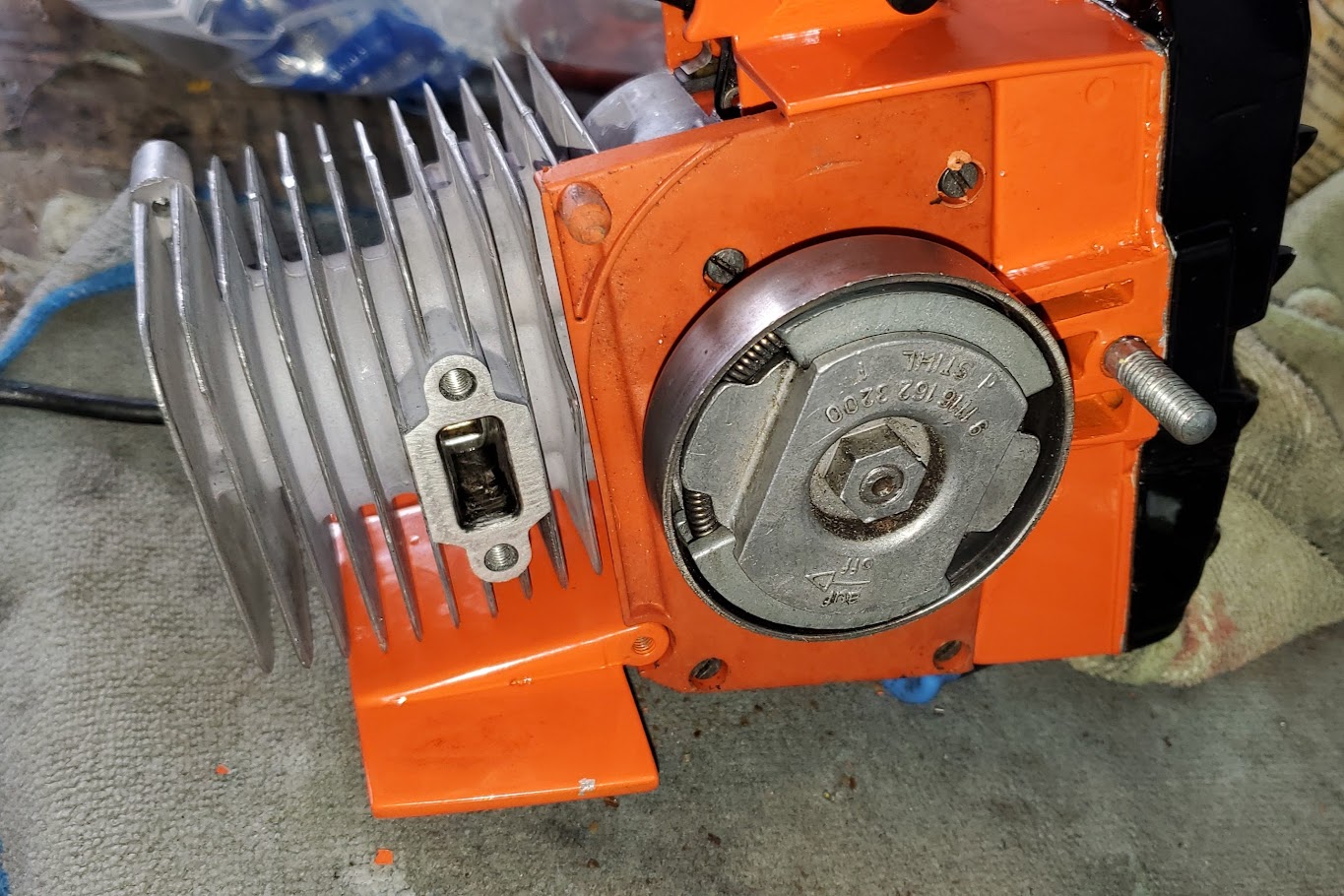

its too damn pretty to use AHHHHHHHHHHHHHHHHHHHHHHHHHH

i got it all buttoned up today..and was rewarded with 187 psi on the compression gauge. tomorrow im gonna put into some smaller trees i need to get rid of along the back fence , this little booger has got a little bark and

lifts the bar on throttle..3 pulls on choke from cold, then choke off and 1 pull has it idling.. i cant believe how much easier its starts with proper compression..

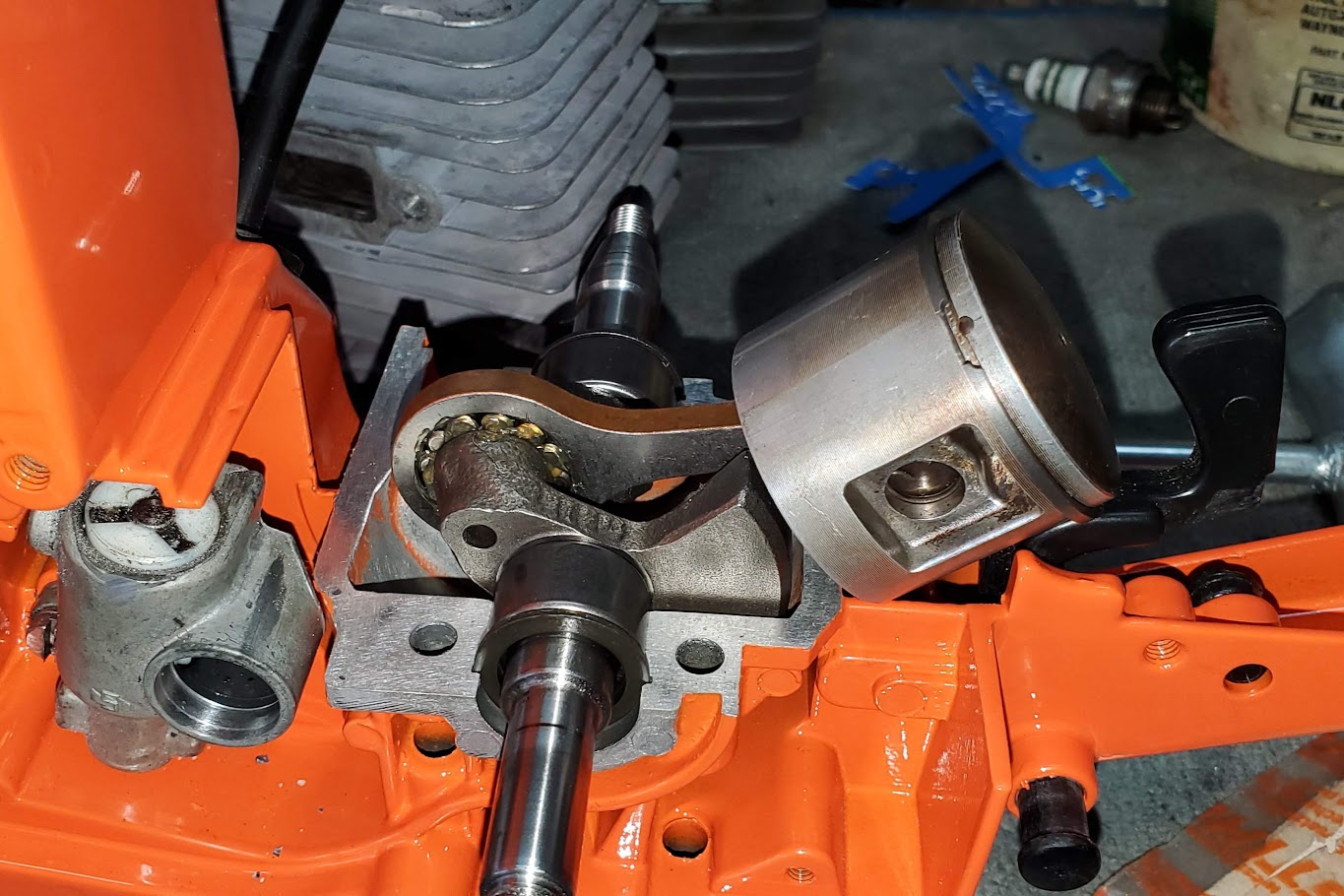

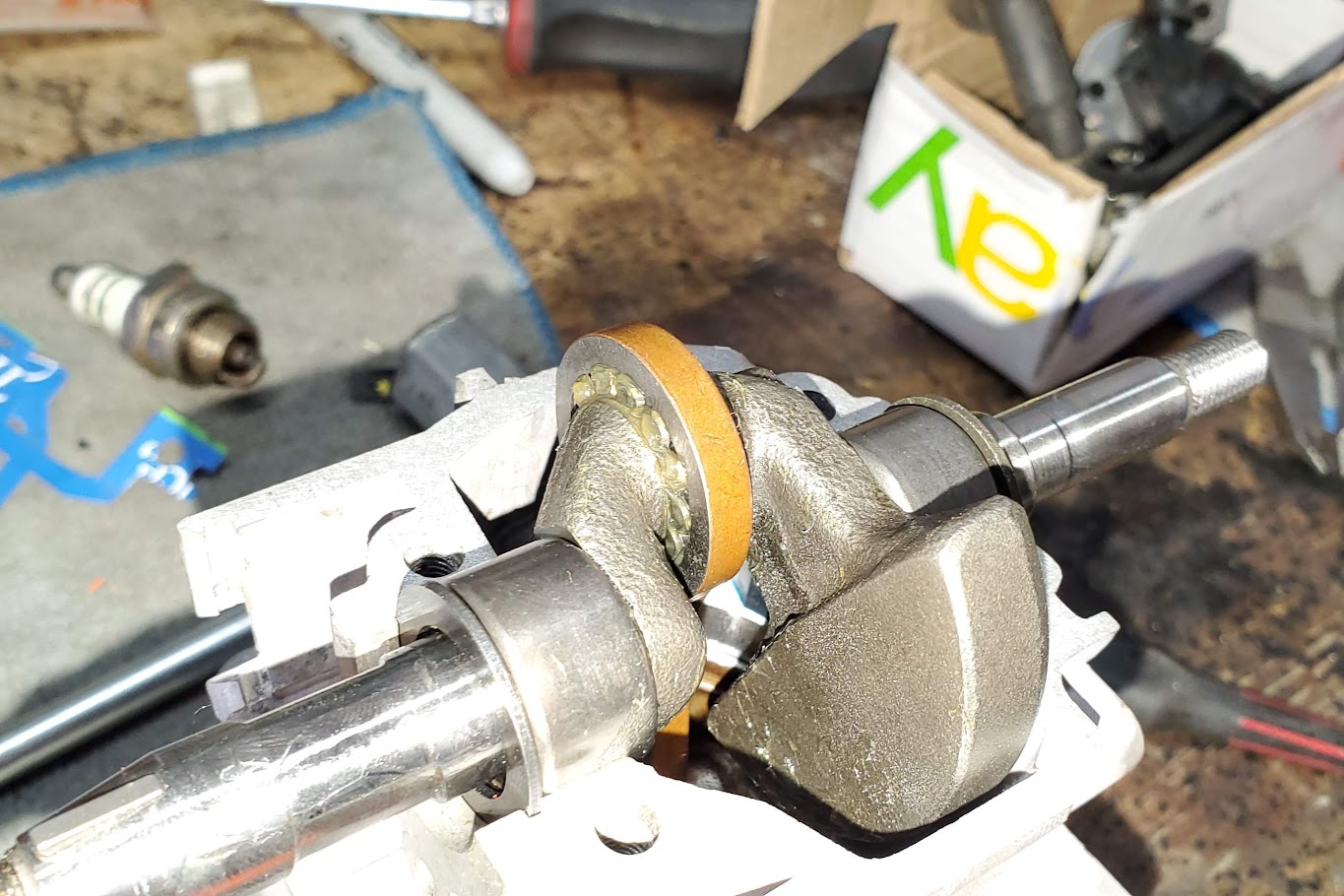

after making gaskets for the crankcase in thicknesses of .003 .007 .015, they did not work... i was trying to get rid of the bearings binding when i tightened the main bolts..i bolted it together one last time without gaskets and the bearings were not binding???????????????????????????????????

only thing i can guess is that bolting the head on 5 or six times kinda made the bearing clamshells relax enough that it worked itself out..

i bolted the halves together and just as the bolts cinched tight, all the slack in the main journal bearings disappeared with no binding at all, perfect..

new paint

NOS cylinder

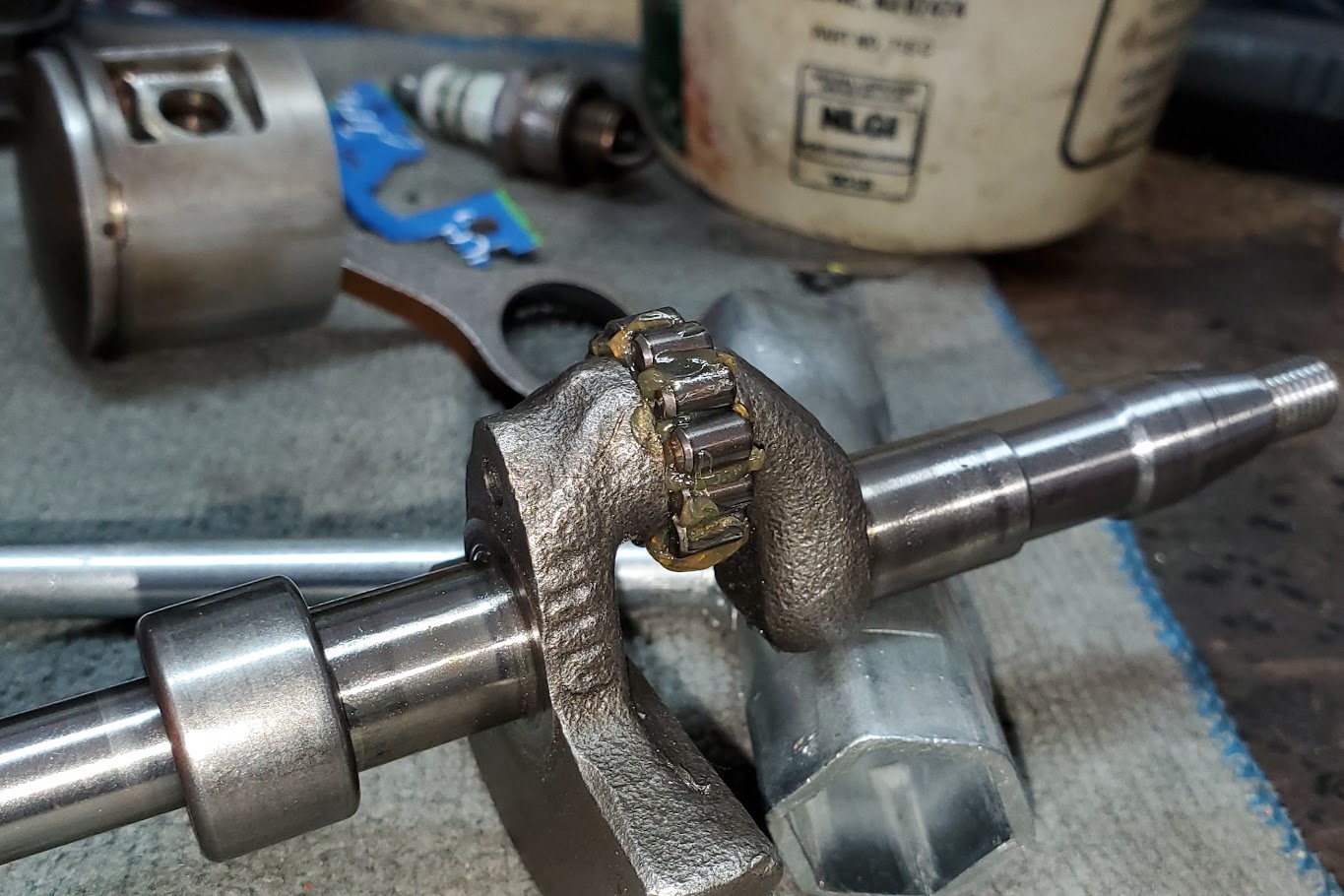

NOS rod

reused oem piston

NOS piston ring

NOS air filter,

used oiler gear cover

converted to 3/8

used clutch drum

NOS needle bearing

rebuilt carb with walbro kit

NOS gaskets and crank seals

new plug

NOS oil pump

NOS coil

NOS plug boot

used stihl 3/8 picco bar and chain

i used only stihl parts

/

i had alot of fun rebuilding this little guy and it will serve me for a long time..i have enough spares that on of my kids can rebuild it one more time if he chooses..

i cost more in paint and NOS parts and phone calls etc etc and time than to just buy an ms270 ...but thats not the point.. these old saws are something special.. when they were made to damn near last forever..

thanks for all your helps fellas..see ya on the next one

no on to the 08s ...then the ts350...then another 015L that i got for free.i think i might try to get my hands on a homelite geared saw to rebuild

i got it all buttoned up today..and was rewarded with 187 psi on the compression gauge. tomorrow im gonna put into some smaller trees i need to get rid of along the back fence , this little booger has got a little bark and

lifts the bar on throttle..3 pulls on choke from cold, then choke off and 1 pull has it idling.. i cant believe how much easier its starts with proper compression..

after making gaskets for the crankcase in thicknesses of .003 .007 .015, they did not work... i was trying to get rid of the bearings binding when i tightened the main bolts..i bolted it together one last time without gaskets and the bearings were not binding???????????????????????????????????

only thing i can guess is that bolting the head on 5 or six times kinda made the bearing clamshells relax enough that it worked itself out..

i bolted the halves together and just as the bolts cinched tight, all the slack in the main journal bearings disappeared with no binding at all, perfect..

new paint

NOS cylinder

NOS rod

reused oem piston

NOS piston ring

NOS air filter,

used oiler gear cover

converted to 3/8

used clutch drum

NOS needle bearing

rebuilt carb with walbro kit

NOS gaskets and crank seals

new plug

NOS oil pump

NOS coil

NOS plug boot

used stihl 3/8 picco bar and chain

i used only stihl parts

/

i had alot of fun rebuilding this little guy and it will serve me for a long time..i have enough spares that on of my kids can rebuild it one more time if he chooses..

i cost more in paint and NOS parts and phone calls etc etc and time than to just buy an ms270 ...but thats not the point.. these old saws are something special.. when they were made to damn near last forever..

thanks for all your helps fellas..see ya on the next one

no on to the 08s ...then the ts350...then another 015L that i got for free.i think i might try to get my hands on a homelite geared saw to rebuild