mtngun

Addicted to ArboristSite

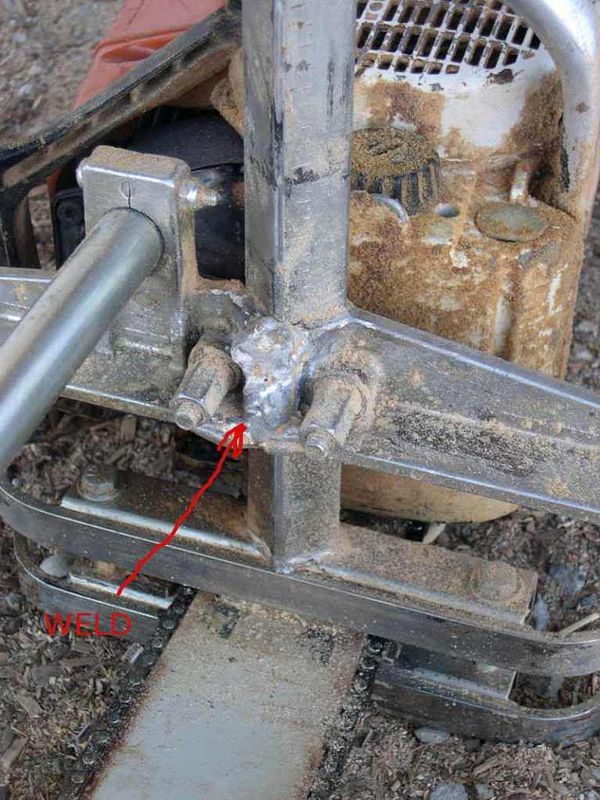

Last time I posted, my Alaskan mill had cracked and the auxilary oiler had plugged up.

I filed out the crack and welded it up with stick. Stick welding small aluminum parts sux, so the repair may eventually fail, but for now it's doing the job. I can't find the pic so I'll have to post it later.

As for the plugged up oiler, I replaced the Granberg supplied fitting with a simple homemade drip tube. Now the oiler drips directly onto the sprocket. Again, I can't find the pics, so I'll have to give you an IOU.

So I was happily milling away with the repaired Alaskan..... and before the ergonomics nazis say anything, I usually mill sitting comfortably on the guide board, but it is necessary to stand up and bend over for the slab cut since the guide board has minimal support on this cut. I don't carry a forklift or sawhorses or jacks around in the woods to lift the log up to a more comfortable position.

These were mostly the tops from the blowdowns I had milled the previous week. I use the tops and other small logs to make 8" x 8" posts, which will come in handy if I ever get around to building a woodshed.

Anyway, after a few hours, the 066 had slowed down noticeably. Thinking the chain was dull, I swapped in a fresh chain, but still the saw was cutting slow.

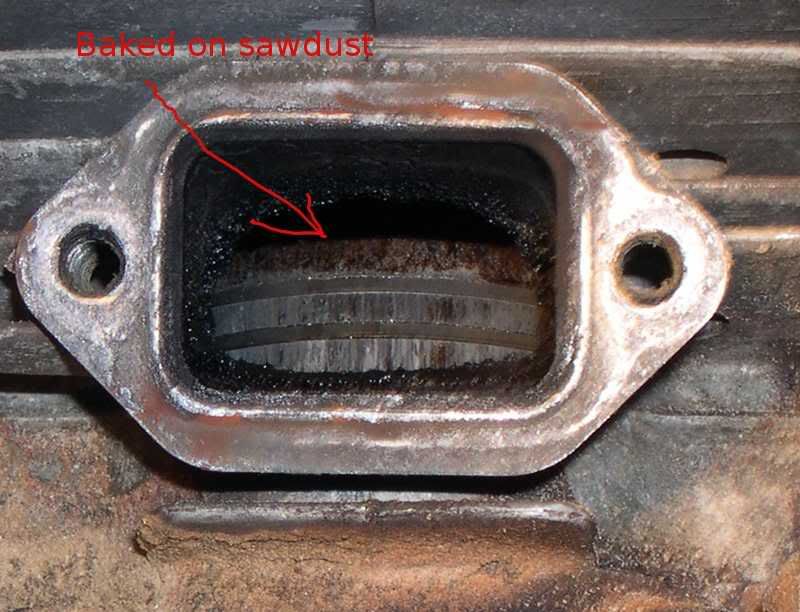

It gradually got worse until it would bog if pushed even a little bit. "Hmmm, maybe the air filter is plugged up", though usually the Stihl air filters continue working well even when they are coated with dust. So I pulled the filter and shook the dust off.

Uh - oh, there was lots of dust inside the filter and on the inner baffle. The filter had not sealed properly. That explains why the saw had gradually gotten weaker. I think I know why it didn't seal, but you'll have to take an IOU on that story.

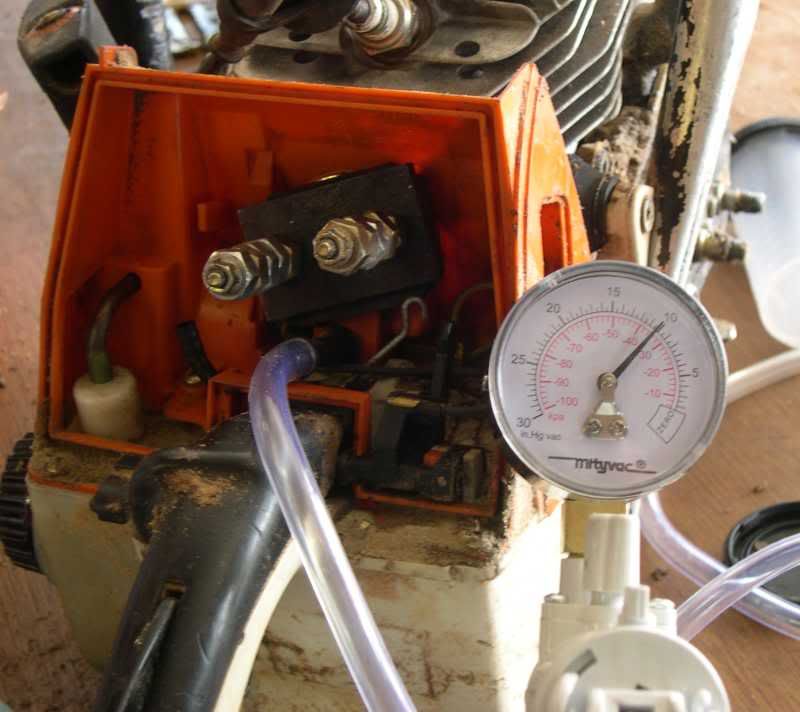

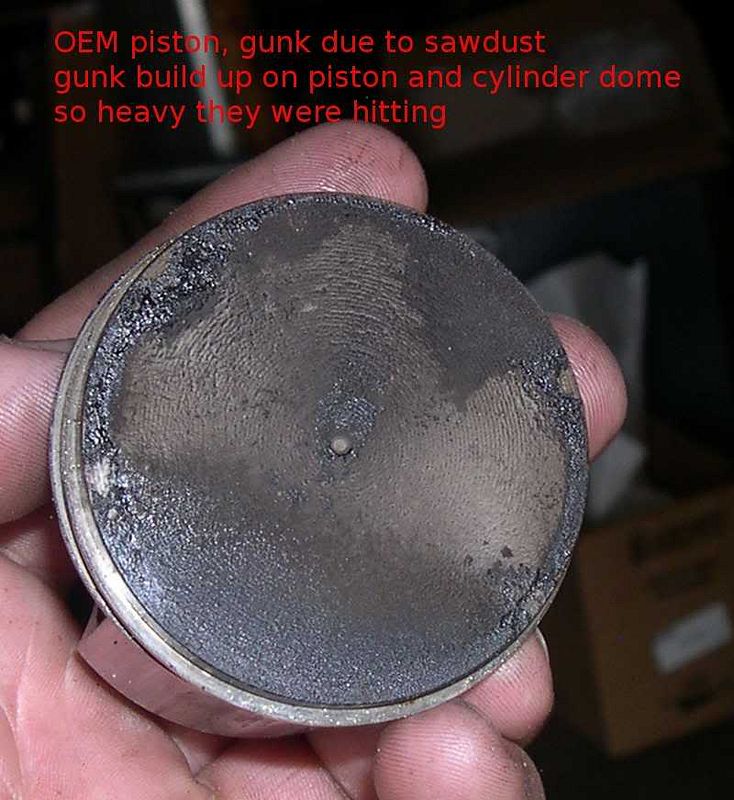

This 066 was tired when I acquired it, and has milled many loads of boards since then. I'd bought a BB kit, seals, a vacuum tester, and a carb kit, but never found time to put them to use. Guess now I'll have to make time. It may be a while before I can schedule the surgery, in the meantime, I'll have to get my milling fix here on Arborsite.

As Roseanne Roseannadanna said, "It's always something."

I filed out the crack and welded it up with stick. Stick welding small aluminum parts sux, so the repair may eventually fail, but for now it's doing the job. I can't find the pic so I'll have to post it later.

As for the plugged up oiler, I replaced the Granberg supplied fitting with a simple homemade drip tube. Now the oiler drips directly onto the sprocket. Again, I can't find the pics, so I'll have to give you an IOU.

So I was happily milling away with the repaired Alaskan..... and before the ergonomics nazis say anything, I usually mill sitting comfortably on the guide board, but it is necessary to stand up and bend over for the slab cut since the guide board has minimal support on this cut. I don't carry a forklift or sawhorses or jacks around in the woods to lift the log up to a more comfortable position.

These were mostly the tops from the blowdowns I had milled the previous week. I use the tops and other small logs to make 8" x 8" posts, which will come in handy if I ever get around to building a woodshed.

Anyway, after a few hours, the 066 had slowed down noticeably. Thinking the chain was dull, I swapped in a fresh chain, but still the saw was cutting slow.

It gradually got worse until it would bog if pushed even a little bit. "Hmmm, maybe the air filter is plugged up", though usually the Stihl air filters continue working well even when they are coated with dust. So I pulled the filter and shook the dust off.

Uh - oh, there was lots of dust inside the filter and on the inner baffle. The filter had not sealed properly. That explains why the saw had gradually gotten weaker. I think I know why it didn't seal, but you'll have to take an IOU on that story.

This 066 was tired when I acquired it, and has milled many loads of boards since then. I'd bought a BB kit, seals, a vacuum tester, and a carb kit, but never found time to put them to use. Guess now I'll have to make time. It may be a while before I can schedule the surgery, in the meantime, I'll have to get my milling fix here on Arborsite.

As Roseanne Roseannadanna said, "It's always something."