So iam new here and i dont know if this is the riht place to post this. So i have two 130ft firs, DBH i would say is 5ft and on one of them iam going to jack it over, but i never used a jack. So any tips, pointers, anything

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

jacking a tree

- Thread starter cooper173

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I have never tried jacking, but I always wanted to try. From what I have read, the equipment to do it properly would be very impractical for just a couple of trees.

Shoot a rope into the top of the tree and pull it over, or hire someone with the equipment and expertise. Cheaper, safer, and more practical.

Shoot a rope into the top of the tree and pull it over, or hire someone with the equipment and expertise. Cheaper, safer, and more practical.

A jack doesn't do much more than a wedge does, except that it has greater travel. If you really need the extra travel of a jack to send the tree over, then you are in a precarious takedown, and should have some expert assistance.

If you just have the jack, and want to use it instead of wedges, go have fun. Advice from me for jacking a tree? I am unqualified, having never done it.

If you just have the jack, and want to use it instead of wedges, go have fun. Advice from me for jacking a tree? I am unqualified, having never done it.

treesquirrel

ArboristSite Guru

When in doubt call an expert. The price might surprise you. I've done simple drop services for as low as 100.00 before and look at it as just good publicity for future business opportunities.

I recently dismantled a large oak for an older gentleman who wanted all the wood for his fireplace and had him done in 2 hours for 3 bills. All I had to do was show up with my climbing gear and my groundie then cut up the trunk and leave. The man had originally planned to have his son come over, throw a rope in it and drop it in the yard. After I explained to him that he would have severely damaged the other trees ( which were beautiful specimens of several varieties of oaks ) in his yard in doing so he agreed that it was better to take it down a piece at a time.

Even though we are in the biz of tree removal it is nice to be able to save some from the mistakes of the uninformed. A pro will point out things you may not think about.

I recently dismantled a large oak for an older gentleman who wanted all the wood for his fireplace and had him done in 2 hours for 3 bills. All I had to do was show up with my climbing gear and my groundie then cut up the trunk and leave. The man had originally planned to have his son come over, throw a rope in it and drop it in the yard. After I explained to him that he would have severely damaged the other trees ( which were beautiful specimens of several varieties of oaks ) in his yard in doing so he agreed that it was better to take it down a piece at a time.

Even though we are in the biz of tree removal it is nice to be able to save some from the mistakes of the uninformed. A pro will point out things you may not think about.

treeslayer

Addicted to ArboristSite

A jack doesn't do much more than a wedge does, except that it has greater travel. If you really need the extra travel of a jack to send the tree over, then you are in a precarious takedown, and should have some expert assistance.

If you just have the jack, and want to use it instead of wedges, go have fun. Advice from me for jacking a tree? I am unqualified, having never done it.

A jack does a hell of a lot more.

20 tons or more, compared to whacking a wedge with a sledgehammer?

if you can properly fell a tree, (key phrase) and can figure out how to get the jack in it, go for it.

$19.99 ($3.33 / Count)

Firewood Log Splitter 45mm+32mm + 4 Handles (Square + Round + Hex Shank + Small Hex) Wood Log Splitter Easy Splitter Detachable Drill Bit Heavy Duty Electric Drills Screw Cone Driver Removable

JianShiMoQinDianZiShangWuYouXianGongSi

$17.99

$19.99

Extendable Pole Saw Branch Trimmer Pruner Head for Tree Trimming Pruning

FENGLICNSAOMV

$142.39

$179.99

ROPE Logic Ultra Ring Sling #3 Riggling Thimble 3/4" Tenex x 6' (40203)

Greener-Garden

$15.95 ($15.95 / Count)

$17.99 ($17.99 / Count)

Fiskars Pole Saw Blade Replacement for Fiskars Pruning Saws and Tree Pruners, 15 Inch Saw Blade with Woodzig Chainsaw-Style Saw Tooth Design

OKB85

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

equipatron

$36.99

$39.99

Wood Kindling Splitter - The Firewood Kindling Tool for Wood Stove Fireplace and Fire Pit

UniExtra

$79.99

$89.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

A jack does a hell of a lot more.

20 tons or more, compared to whacking a wedge with a sledgehammer?

if you can properly fell a tree, (key phrase) and can figure out how to get the jack in it, go for it.

:agree2: Just make sure you have a very strong jack, you don't want it failing on you. The shock could snap the hinge and send the tree the wrong way. I did it with an 8 ton jack once but I wouldn't recommend it. I was in a bind and had to get the tree over. I also had a rope in the top of the tree tied to a 5:1 pulley. I would go with what slayer said, at least a 20 ton jack. I recently purchased 20 ton jack for a fairly cheap price $70. Also you need some kind of heavy thick steel plate to put between the jack and the tree so the jack doesn't dig into the tree.

Last edited:

A jack does a hell of a lot more.

20 tons or more, compared to whacking a wedge with a sledgehammer?

if you can properly fell a tree, (key phrase) and can figure out how to get the jack in it, go for it.

Sure. Jacks make it easier to apply lots of pressure, but distinctly NOT more reliable than wedges, and nowhere near as inexpensive or practical to use.

First: you need a specialized tree jack with extra wide plates on the top & bottom. Otherwise the 20 tons of force you may be applying will just bury the top cylinder into the wood, possibly splitting the trunk and setting back on the cut. If you just stick a metal plate in the middle, it greatly increases your chances of jumping out of the cut under load. See #2.

2nd: jacks can kick out. The cuts need to be very carefully made parallel.

3rd: the jack can fail, also allowing the tree to set back.

Unless I am mistaken, most of the specialized tree jacks are in the 50-100 ton range, and are much lower profile than your typical hydraulic jack

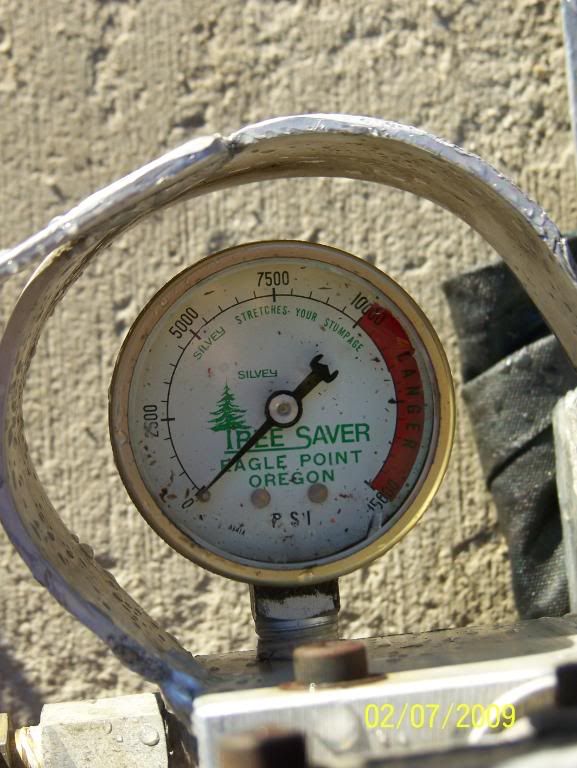

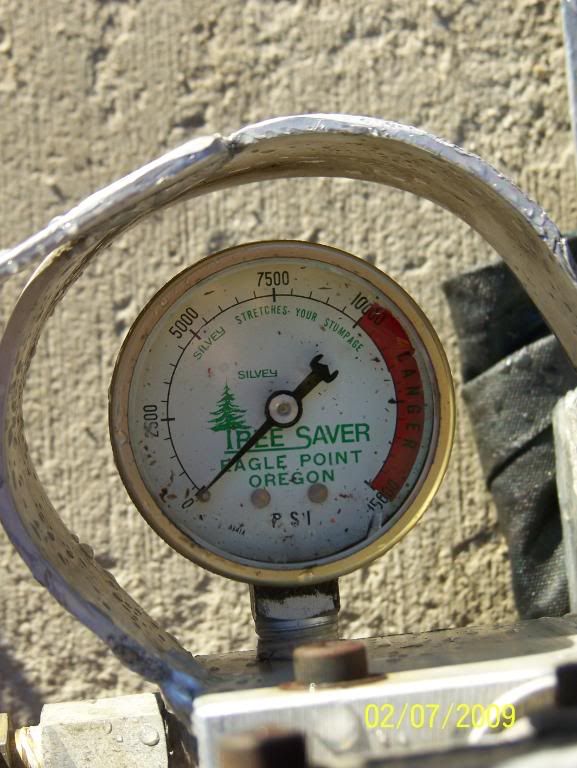

Here is a guide to tree felling in Oregon, which includes some rules for using tree jacks. Notice the special requirement for a working pressure gauge on the jack: http://www.orosha.org/pdf/rules/division_7/div7_i.pdf

Here is a nice sales blurb from Silvey that shows their jacks in use. Notice that the minimum tonnage in use is 45 tons for a standalone jack, and 35 tons for "Little Feller" that is meant to be used in pairs.

http://www.madsens1.com/sil jacks.htm

I don't have anything at all against jacking a tree. I just know that it is a very specialized variety of tree felling that should not be attempted by a newbie on a technical job, and that would include myself. If it is not a technically challenging job, then why go to the trouble of using the jack?

Last edited:

SINGLE-JACK

ArboristSite Guru

:agree2:Sure. Jacks make it easier to apply lots of pressure, but distinctly NOT more reliable than wedges, and nowhere near as inexpensive or practical to use.

First: you need a specialized tree jack with extra wide plates on the top & bottom. Otherwise the 20 tons of force you may be applying will just bury the top cylinder into the wood, possibly splitting the trunk and setting back on the cut. If you just stick a metal plate in the middle, it greatly increases your chances of jumping out of the cut under load. See #2.

2nd: jacks can kick out. The cuts need to be very carefully made parallel.

3rd: the jack can fail, also allowing the tree to set back.

Unless I am mistaken, most of the specialized tree jacks are in the 50-100 ton range, and are much lower profile than your typical hydraulic jack

Here is a guide to tree felling in Oregon, which includes some rules for using tree jacks: http://www.orosha.org/pdf/rules/division_7/div7_i.pdf

Here is a nice sales blurb from Silvey that shows their jacks in use. Notice that the minimum tonnage in use is 45 tons for a standalone jack, and 35 tons for "Little Feller" that is meant to be used in pairs.

http://www.madsens1.com/sil jacks.htm

I don't have anything at all against jacking a tree. I just know that it is a very specialized variety of tree felling that should not be attempted by a newbie on a technical job, and that would include myself. If it is not a technically challenging job, then why go to the trouble of using the jack?

If there's any way you can rig a hold line & a pull line - they're a lot safer, IMO.

"Kick out", "set back" & cutting around a "failed jack" are dangerous risks. Plus the "specialized tree jack" is very EXPENSIVE. All of those reason have kept me from trying it.

I've only seen it done once. There were two Silvey jacks used. They hadn't been used in years. One of them failed - seal blew out. It took forever to wedge it out, fix it and get it back in and finish the job.

That being said, proper jacks are a really good tools for those experienced with them. I don't know but, I've been told they are a last resort. So, be careful.

ForTheArborist

Addicted to ArboristSite

To remedy the jack head boring into the tree, I think that something like an 8x6" piece of 1/2" or 3/8" steel steel plate would prevent. The thing is that the jack head is going to slip out from under the steel plate beings that jack heads of small diameters.

To remedy the slippage I think that the first plate should be welded to a second plate with a hole cut out in the center that fits the jack head. The jack head will lie within that hole, and the surrounding metal will prevent it from slipping anywhere.

The holding metal added to the primary plate could be something like a plate that matches the primary plate, but I would prefer it if I could fab something to the primary plate that covered the jack head by at least 1/2" to 1 full inch. The reason is that with tons of pressure therein, I envision that as the tree base begins to angle upward the plate might be shot out causing injury or at least just making the plate come off of the jack, therefore disrupting the entire system leading to who knows what. I'd have to see the jacks being used a few times to know the right height for the jack head stabilizing application.

To remedy the slippage I think that the first plate should be welded to a second plate with a hole cut out in the center that fits the jack head. The jack head will lie within that hole, and the surrounding metal will prevent it from slipping anywhere.

The holding metal added to the primary plate could be something like a plate that matches the primary plate, but I would prefer it if I could fab something to the primary plate that covered the jack head by at least 1/2" to 1 full inch. The reason is that with tons of pressure therein, I envision that as the tree base begins to angle upward the plate might be shot out causing injury or at least just making the plate come off of the jack, therefore disrupting the entire system leading to who knows what. I'd have to see the jacks being used a few times to know the right height for the jack head stabilizing application.

I would def weld the steel plate to the cylinder head to prevent slippage and injury. In most cases you only need 2 or 3 inches of lift to get the tree over center. Once over center the tree is going to go where it goes. I wouldn't rely solly on the jack for felling, it can come in handy if you are in a bind and need some muscle to lift the tree. If you are going to be using a jack I would make some wedges out of wood at different thicknesses to set as spacers for a back-up in case of slippage. Again it can be risky if you're not experienced with using a jack.

I only jack the trees that have a heavy back lean. I have jacked many over with a 30 ton enerpac RCS 302 (hand pump, liquid filled gage and 10' hose. If at all possible, always put a pull rope in first. I like to use 3/4" or bigger nylon as it gives a longer pull from the stretch, but use a rope you can't pull apart. To prevent it from sitting back, Back up the lift with wedges. Thick shoring type hardwood when you run out of travel with plastic ones, just in case the jack kicks out. Strap the trunk above your cut to contain the possible barbers chair. As stated previously, the use of a pressure gage is important. I carefully notch, start my back-cut but stop when I clear enough space for the jack diameter. Then cut out a block for the jack head below the back cut, insert the jack and snug it up until I see a slight pressure drop at the end of each stroke, which indicates the wood is starting to yield and the jack head is burying slightly into the wood. This helps keep the jack from kicking out. Then carefully continue the back cut until you have the desired hinge thickness. Watch the pressure gage as you cut, but DON'T cut your hinge off. Remember, the notch and the back cut both serve to leave you a nice, even, well aimed hinge with the correct thickness for the tree you are dropping. This is what determines where the tree will land. As soon as the pressure starts to drop, the tree is moving, even if you can't see it.

Stop cutting, back away at a 45 and give it a few more strokes, gravity will do the rest.

Stop cutting, back away at a 45 and give it a few more strokes, gravity will do the rest.

I only jack the trees that have a heavy back lean. I have jacked many over with a 30 ton enerpac RCS 302 (hand pump, liquid filled gage and 10' hose. If at all possible, always put a pull rope in first. I like to use 3/4" or bigger nylon as it gives a longer pull from the stretch, but use a rope you can't pull apart. To prevent it from sitting back, Back up the lift with wedges. Thick shoring type hardwood when you run out of travel with plastic ones, just in case the jack kicks out. Strap the trunk above your cut to contain the possible barbers chair. As stated previously, the use of a pressure gage is important. I carefully notch, start my back-cut but stop when I clear enough space for the jack diameter. Then cut out a block for the jack head below the back cut, insert the jack and snug it up until I see a slight pressure drop at the end of each stroke, which indicates the wood is starting to yield and the jack head is burying slightly into the wood. This helps keep the jack from kicking out. Then carefully continue the back cut until you have the desired hinge thickness. Watch the pressure gage as you cut, but DON'T cut your hinge off. Remember, the notch and the back cut both serve to leave you a nice, even, well aimed hinge with the correct thickness for the tree you are dropping. This is what determines where the tree will land. As soon as the pressure starts to drop, the tree is moving, even if you can't see it.

Stop cutting, back away at a 45 and give it a few more strokes, gravity will do the rest.

That pretty much sums it up, good info Panama. So you don't recommend using a jack without a pressure gage?

Greystoke

Tarzan

Tree Jacks

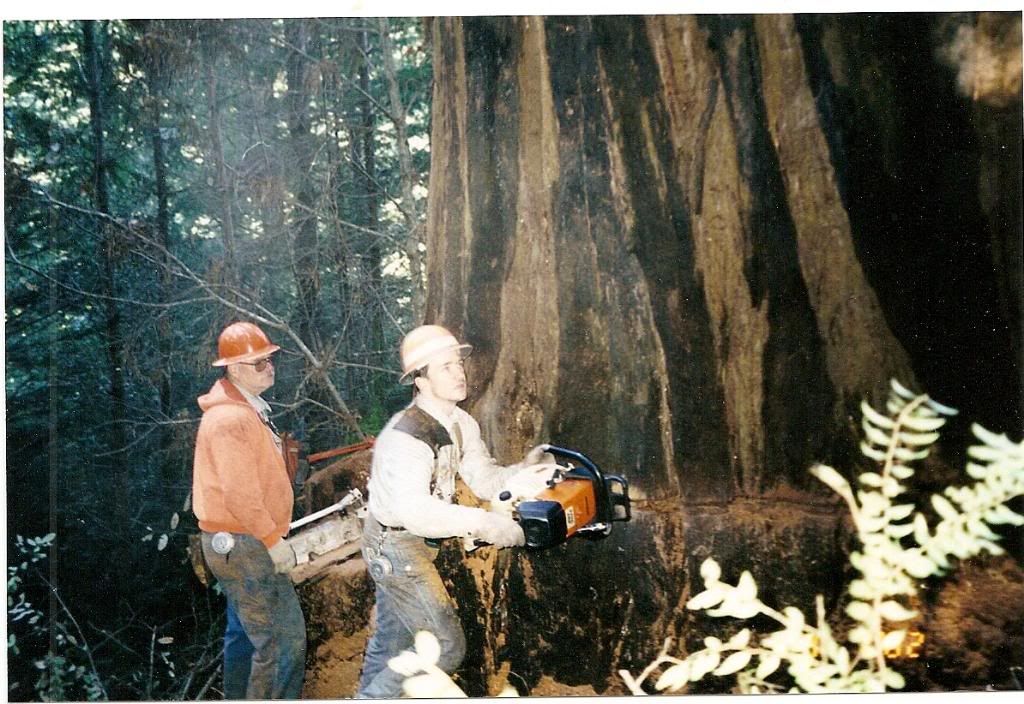

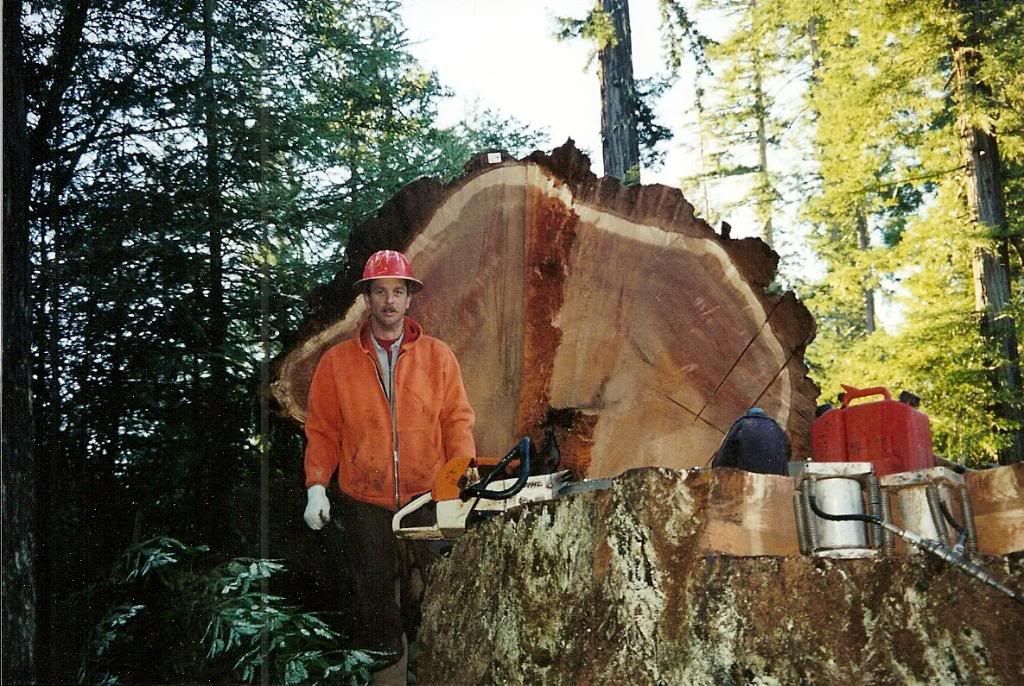

The Real tree jacks are awesome in the right application, as I used them quite a bit when I was falling timber, especially on the coast. I have only ever used the Silvey tree-savers which have the most capacity which is 124 tons. I own a set of tree-savers which I have only used on one urban setting which was a large dead but SOUND Cottonwood. The holding wood or hinge wood must be sound enough to accept the torque and the wood for the jack seat should be fairly sound, although you can use jack plates to spread the pressure on punky wood. Most of the time I install a bull line and pull over the tree in an urban setting. Here are some pictures of my set of jacks:

This is a picture of them stowed so that you can pack them on your back...They are heavy especially on rugged ground.

Here is a picture of them hooked to the hose and jacked to the red line (maximum height) They have a lift height of 5 5/8".

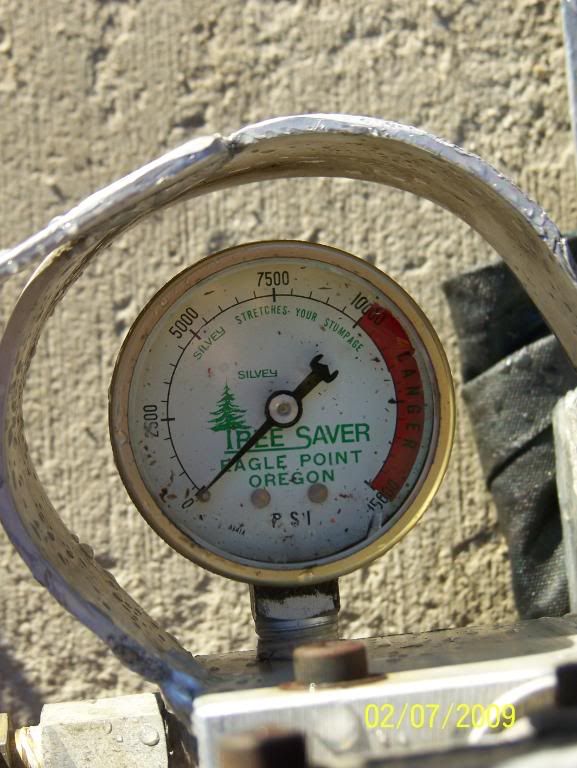

Here is one of the best things about them...the gauge that tells you what the tree is doing...setting back or going over the way you want.

Here are a few pictures I have of them in use.

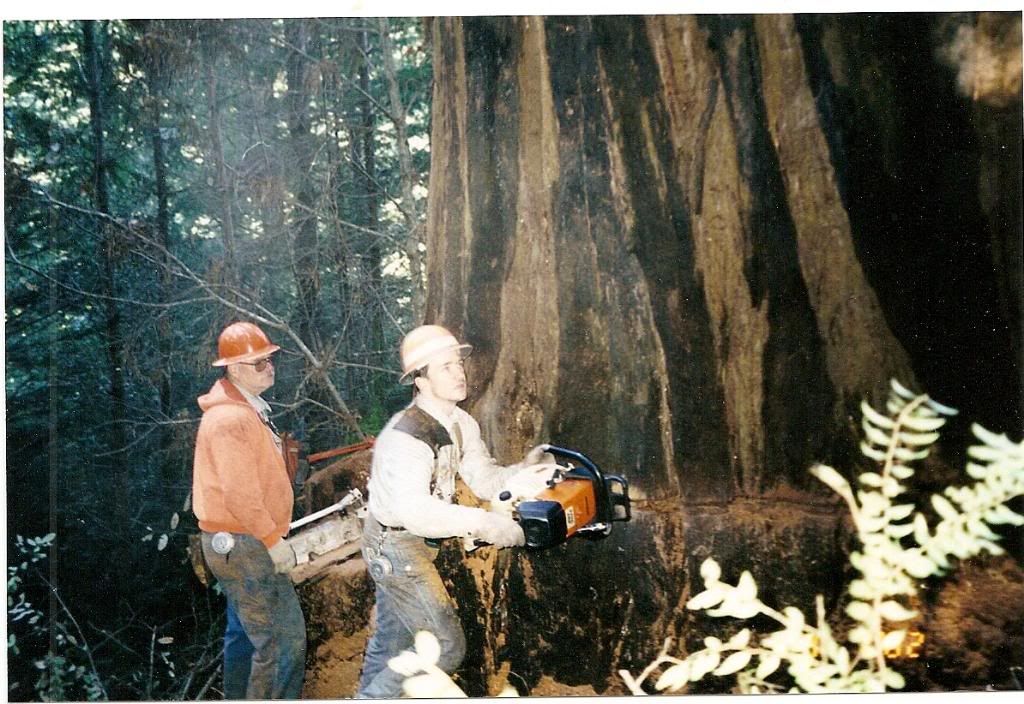

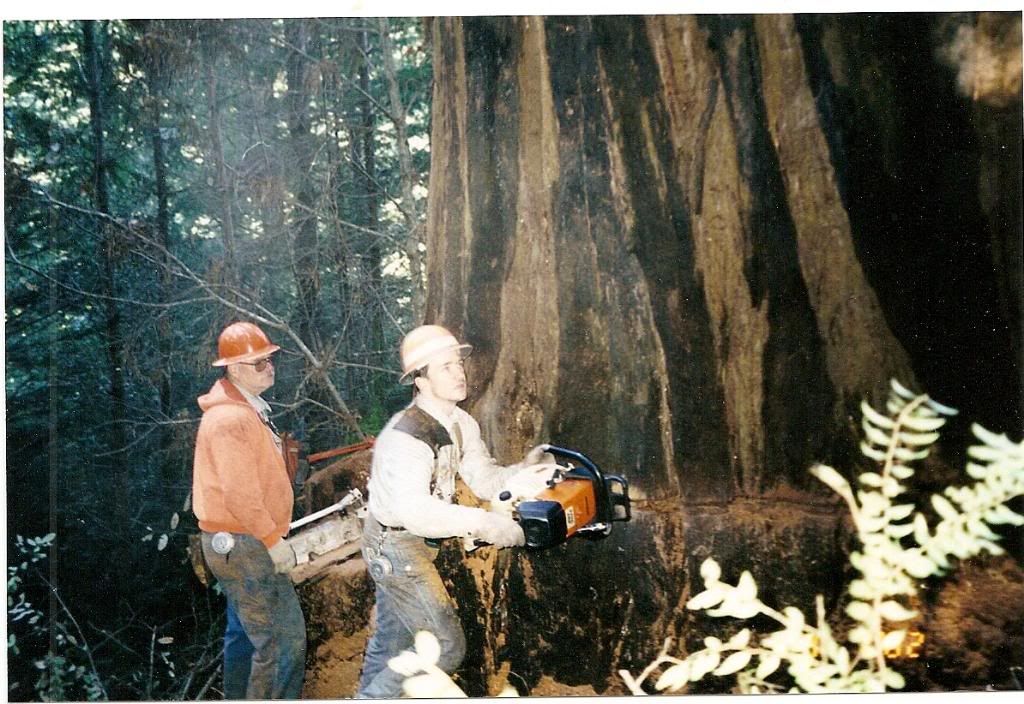

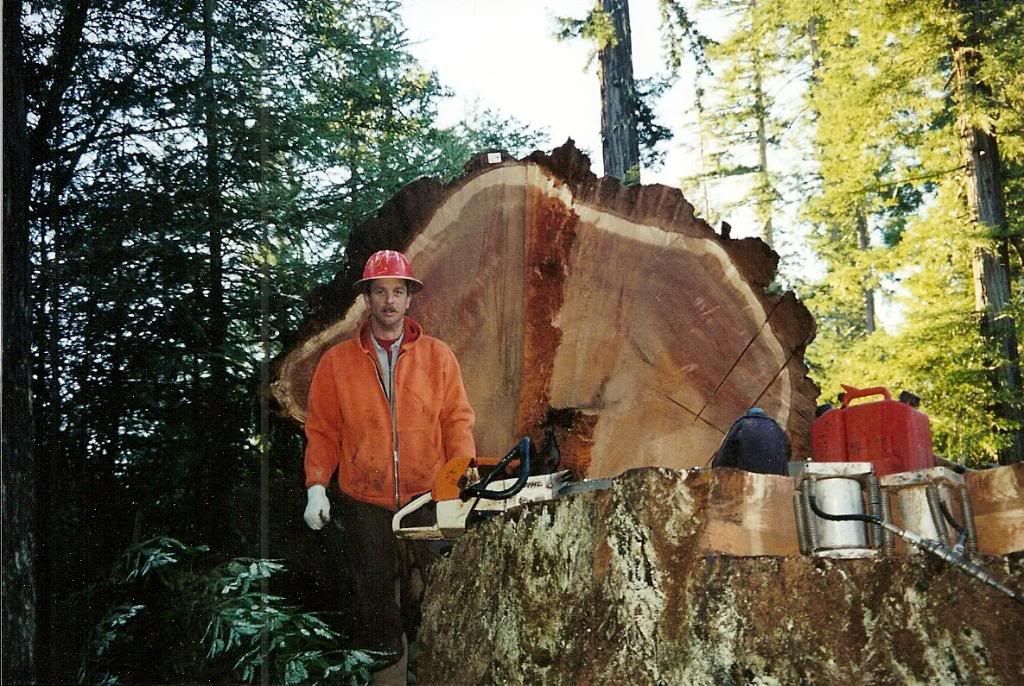

Here I am falling a redwood; Notice the guy behind me...he is putting pressure on the rams by jacking, and also he is watching the gauge as I am putting the undercut in this glorious tree.

Here is a picture of an excellent timber faller cleaning out the end of the hose to connect the pump to the rams. Notice the jack seat in the background.

\

\

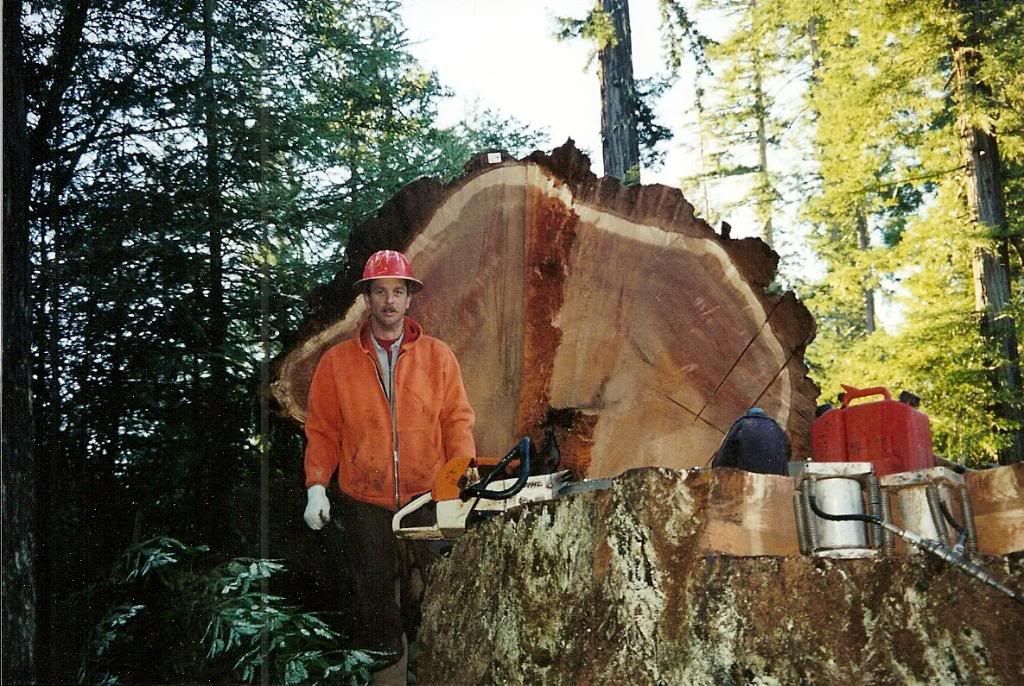

Here is another excellent timber faller after we jacked over a nice redwood. This was after we opened the valve on the jacks to return them to their lowest position.

Sorry for the long post, I just get a little excited when somebody brings up jacking timber, as it makes me remember the glorious times I had doing it. Jacks definitely have their place, but I kind of think they are more suited for logging applications, although I will probably never get rid of mine, because I am sure that I will use them again on the right tree.

The Real tree jacks are awesome in the right application, as I used them quite a bit when I was falling timber, especially on the coast. I have only ever used the Silvey tree-savers which have the most capacity which is 124 tons. I own a set of tree-savers which I have only used on one urban setting which was a large dead but SOUND Cottonwood. The holding wood or hinge wood must be sound enough to accept the torque and the wood for the jack seat should be fairly sound, although you can use jack plates to spread the pressure on punky wood. Most of the time I install a bull line and pull over the tree in an urban setting. Here are some pictures of my set of jacks:

This is a picture of them stowed so that you can pack them on your back...They are heavy especially on rugged ground.

Here is a picture of them hooked to the hose and jacked to the red line (maximum height) They have a lift height of 5 5/8".

Here is one of the best things about them...the gauge that tells you what the tree is doing...setting back or going over the way you want.

Here are a few pictures I have of them in use.

Here I am falling a redwood; Notice the guy behind me...he is putting pressure on the rams by jacking, and also he is watching the gauge as I am putting the undercut in this glorious tree.

Here is a picture of an excellent timber faller cleaning out the end of the hose to connect the pump to the rams. Notice the jack seat in the background.

Here is another excellent timber faller after we jacked over a nice redwood. This was after we opened the valve on the jacks to return them to their lowest position.

Sorry for the long post, I just get a little excited when somebody brings up jacking timber, as it makes me remember the glorious times I had doing it. Jacks definitely have their place, but I kind of think they are more suited for logging applications, although I will probably never get rid of mine, because I am sure that I will use them again on the right tree.

joesawer

Addicted to ArboristSite

http://www.arboristsite.com/showthr....com/showthread.php?t=90970&highlight=jacking

http://www.arboristsite.com/showthread.php?t=69827

Here is a couple of links.

Post this question in the forestry forum if you want answers from people who have actually used jacks.

http://www.arboristsite.com/showthread.php?t=69827

Here is a couple of links.

Post this question in the forestry forum if you want answers from people who have actually used jacks.

treeclimber101

UNCLE BUCK

A couple of those pics are magazine cover worthy, I like them thanks for the post..The Real tree jacks are awesome in the right application, as I used them quite a bit when I was falling timber, especially on the coast. I have only ever used the Silvey tree-savers which have the most capacity which is 124 tons. I own a set of tree-savers which I have only used on one urban setting which was a large dead but SOUND Cottonwood. The holding wood or hinge wood must be sound enough to accept the torque and the wood for the jack seat should be fairly sound, although you can use jack plates to spread the pressure on punky wood. Most of the time I install a bull line and pull over the tree in an urban setting. Here are some pictures of my set of jacks:

This is a picture of them stowed so that you can pack them on your back...They are heavy especially on rugged ground.

Here is a picture of them hooked to the hose and jacked to the red line (maximum height) They have a lift height of 5 5/8".

Here is one of the best things about them...the gauge that tells you what the tree is doing...setting back or going over the way you want.

Here are a few pictures I have of them in use.

Here I am falling a redwood; Notice the guy behind me...he is putting pressure on the rams by jacking, and also he is watching the gauge as I am putting the undercut in this glorious tree.

Here is a picture of an excellent timber faller cleaning out the end of the hose to connect the pump to the rams. Notice the jack seat in the background.

\

Here is another excellent timber faller after we jacked over a nice redwood. This was after we opened the valve on the jacks to return them to their lowest position.

Sorry for the long post, I just get a little excited when somebody brings up jacking timber, as it makes me remember the glorious times I had doing it. Jacks definitely have their place, but I kind of think they are more suited for logging applications, although I will probably never get rid of mine, because I am sure that I will use them again on the right tree.

treemandan

Tree Freak

Yeah Tarzan, your post was chock full of good info and specs. You just taught the world how to do it basically.

ShoerFast

Tree Freak

- Joined

- Nov 14, 2005

- Messages

- 25,843

- Reaction score

- 17,234

I've used bottle-jacks to drop little trees where i needed them to go.

Wore out wide rasp, or cut out a hardwood shim, works well to keep the jacks from sinking in the wood, leave a little more hinge and move it over.

We all know that there could be a lot of things that could go wrong, but you can sure save some work by putting a tree where you want it to go and not where it wants to go.

Wore out wide rasp, or cut out a hardwood shim, works well to keep the jacks from sinking in the wood, leave a little more hinge and move it over.

We all know that there could be a lot of things that could go wrong, but you can sure save some work by putting a tree where you want it to go and not where it wants to go.

They are scary to me. Hey Joesawer, I was in Crestline and Arrowhead during the Phillips and Jordan Edison Bark Beetle Removals in 2003. There were some tricky trees there!

Jeff

Jeff

Similar threads

- Replies

- 8

- Views

- 880

- Replies

- 1

- Views

- 252

- Replies

- 1

- Views

- 792