gekko

ArboristSite Operative

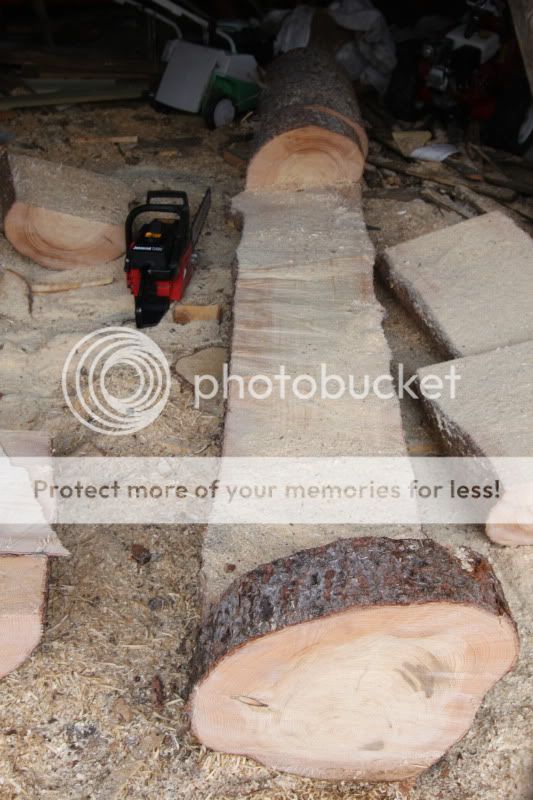

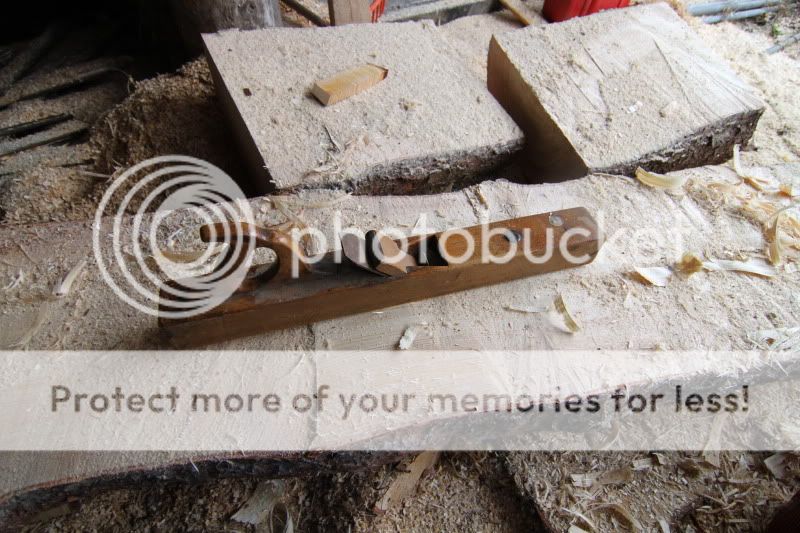

Making a bench

I have been thinking about making a new garden table for my parents since the table we got noe isn't exactly pretty with pressure treated wood on concrete blocks.

The very basic idea i have been thinking of is this (Great paint skills :monkey

:monkey

if someone has built something similar, i could use some general tips and such

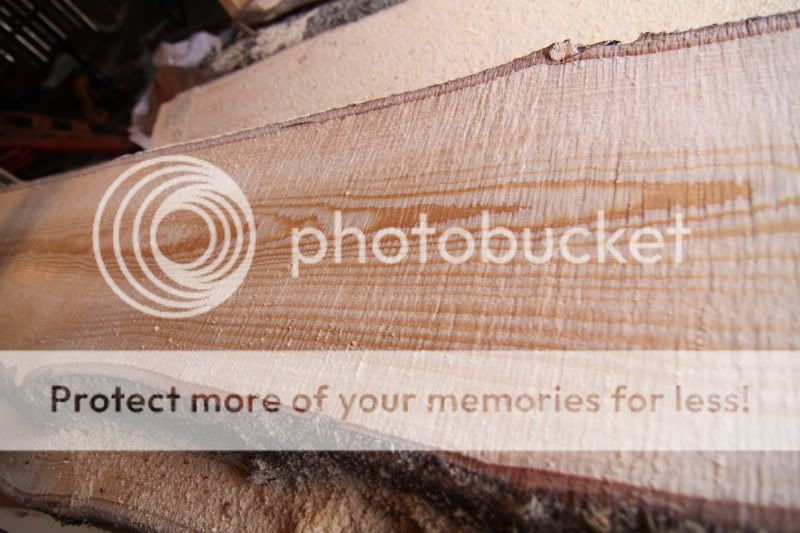

The wood im thinking about using atm is spruce since we have a planted field of them and they are the straightest wood we have.

Also, should i start working with the wood as soon as possible after felling or should i wait a while?

Thanks-

also i think i missed a couple of letters in the title

I have been thinking about making a new garden table for my parents since the table we got noe isn't exactly pretty with pressure treated wood on concrete blocks.

The very basic idea i have been thinking of is this (Great paint skills

if someone has built something similar, i could use some general tips and such

The wood im thinking about using atm is spruce since we have a planted field of them and they are the straightest wood we have.

Also, should i start working with the wood as soon as possible after felling or should i wait a while?

Thanks-

also i think i missed a couple of letters in the title

Last edited: