Tzed250

Addicted to ArboristSite

I have had a couple of 28" NOS McCulloch sprocket nose bars hanging around for a while. I decided that I would modify one to fit my SP125C so that I could do some work to my 36" bar. The 28" bar was originally made to fit the saws that include the 10-10, PM700, 610, etc. The slot on that bar is .320" wide (5/16" nominal). The slot on the large mount bars is .390" (3/8" nominal). A trip to the Bridgeport was in order.

After using two heel clamps to secure the bar to the table, I used an edge finder to locate the center of the slot.

<a href="http://www.flickr.com/photos/41385771@N03/5316769477/" title="Untitled by zweitakt250, on Flickr"><img src="http://farm6.static.flickr.com/5044/5316769477_4df62e077d_z.jpg" width="640" height="480" alt="" /></a>

The tool that I used was a .375" 4-flute solid carbide end mill. Bar steel is very tough. It can be cut with high speed steel, but your surface speed must be much lower than with carbide. One pass down the center, then a .007" pass up each side set the width at .39"

<a href="http://www.flickr.com/photos/41385771@N03/5316761451/" title="Bar Slot by zweitakt250, on Flickr"><img src="http://farm6.static.flickr.com/5084/5316761451_f6a6152338_z.jpg" width="640" height="480" alt="Bar Slot" /></a>

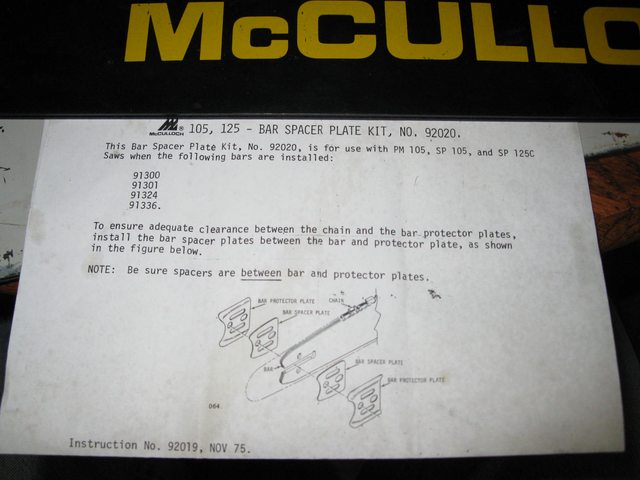

Because the tail on the smaller bar is more narrow than the large bar I had to modify a set of spacer plates so that the chain rivets would not drag on the larger bar plates. After scribing the profile from the small bar, the plates were shaped on a belt sander. You can see the size difference between the stock plate and the narrowed plate in the pictures.

<a href="http://www.flickr.com/photos/41385771@N03/5317360474/" title="Spacer plate by zweitakt250, on Flickr"><img src="http://farm6.static.flickr.com/5121/5317360474_5eaa269131_z.jpg" width="640" height="480" alt="Spacer plate" /></a>

I ordered a new square ground Oregon chain, along with an 8 tooth sprocket, from Bailey's and that gave me everything I needed. It all went together without a hitch.

<a href="http://www.flickr.com/photos/41385771@N03/5316739405/" title="SP newbar by zweitakt250, on Flickr"><img src="http://farm6.static.flickr.com/5282/5316739405_526bff9747_z.jpg" width="832" height="553" alt="SP newbar" /></a>

Now, if Spring will just get here...

.

After using two heel clamps to secure the bar to the table, I used an edge finder to locate the center of the slot.

<a href="http://www.flickr.com/photos/41385771@N03/5316769477/" title="Untitled by zweitakt250, on Flickr"><img src="http://farm6.static.flickr.com/5044/5316769477_4df62e077d_z.jpg" width="640" height="480" alt="" /></a>

The tool that I used was a .375" 4-flute solid carbide end mill. Bar steel is very tough. It can be cut with high speed steel, but your surface speed must be much lower than with carbide. One pass down the center, then a .007" pass up each side set the width at .39"

<a href="http://www.flickr.com/photos/41385771@N03/5316761451/" title="Bar Slot by zweitakt250, on Flickr"><img src="http://farm6.static.flickr.com/5084/5316761451_f6a6152338_z.jpg" width="640" height="480" alt="Bar Slot" /></a>

Because the tail on the smaller bar is more narrow than the large bar I had to modify a set of spacer plates so that the chain rivets would not drag on the larger bar plates. After scribing the profile from the small bar, the plates were shaped on a belt sander. You can see the size difference between the stock plate and the narrowed plate in the pictures.

<a href="http://www.flickr.com/photos/41385771@N03/5317360474/" title="Spacer plate by zweitakt250, on Flickr"><img src="http://farm6.static.flickr.com/5121/5317360474_5eaa269131_z.jpg" width="640" height="480" alt="Spacer plate" /></a>

I ordered a new square ground Oregon chain, along with an 8 tooth sprocket, from Bailey's and that gave me everything I needed. It all went together without a hitch.

<a href="http://www.flickr.com/photos/41385771@N03/5316739405/" title="SP newbar by zweitakt250, on Flickr"><img src="http://farm6.static.flickr.com/5282/5316739405_526bff9747_z.jpg" width="832" height="553" alt="SP newbar" /></a>

Now, if Spring will just get here...

.