Definitive Dave

wanna-be saw racer, saw hoarder, parts whore

- Joined

- Jul 27, 2013

- Messages

- 2,118

- Reaction score

- 5,087

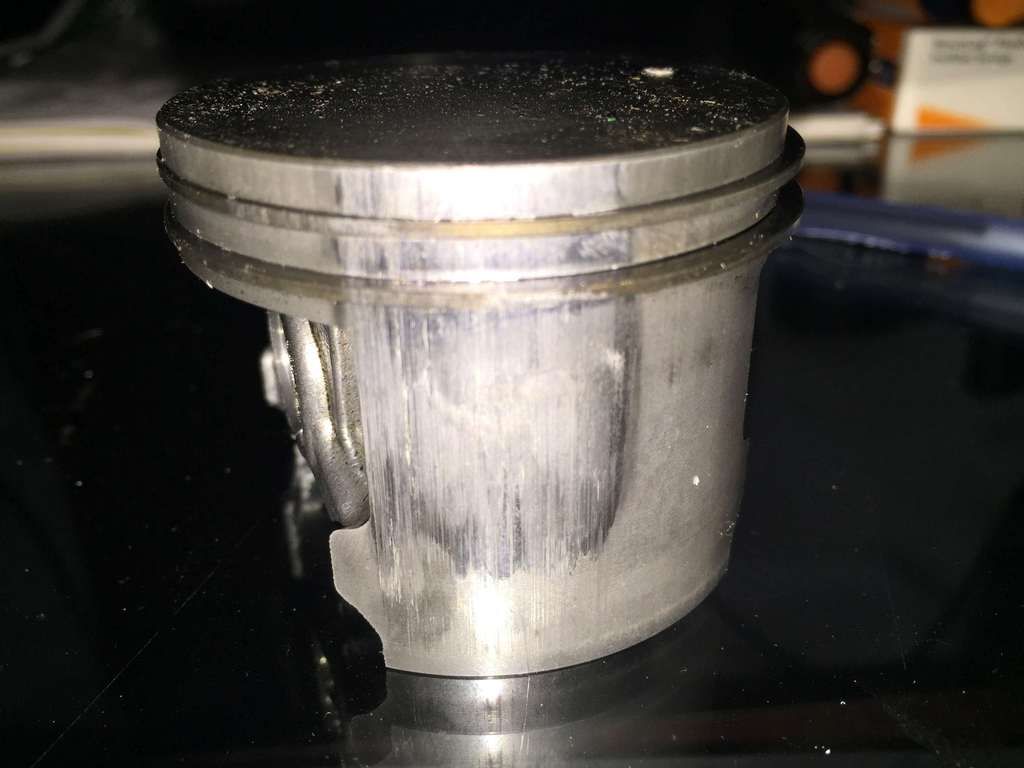

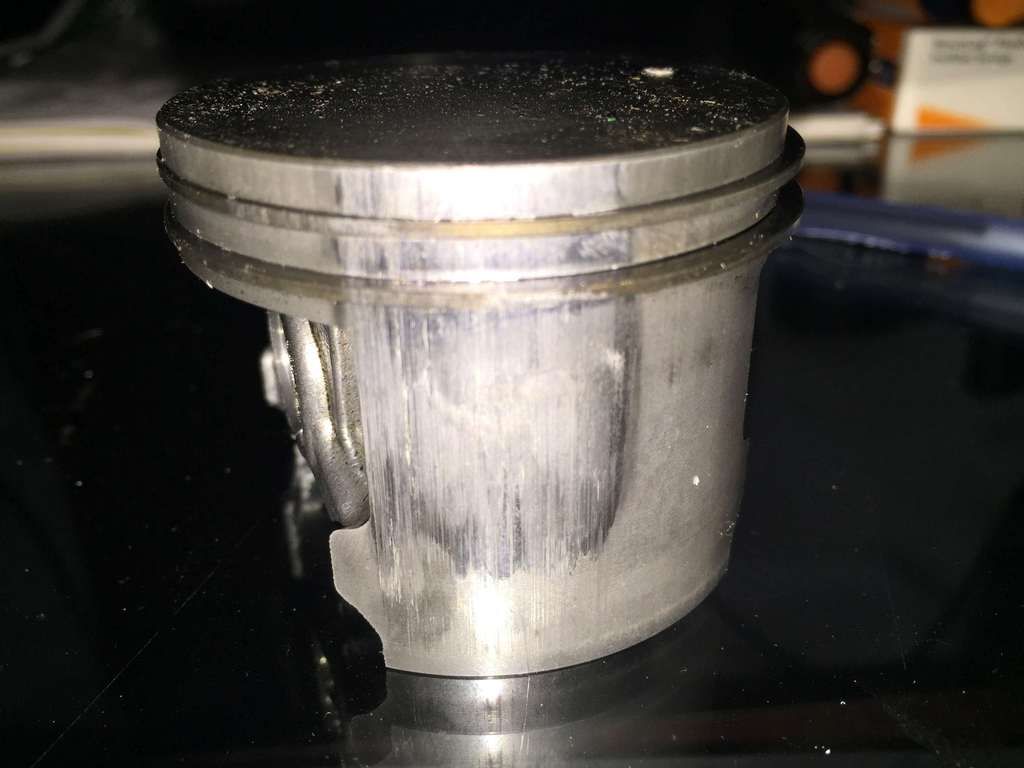

Cliff's Notes for the TL R crowd : light markings, slight ring scratching, what happened?

R crowd : light markings, slight ring scratching, what happened?

Details for the enlightened: About 3 weeks ago a customer bought a pair of Meteor MS660 / 066 cylinder kits from me and took his pair of older 064AV saws to his Stihl dealer for overhaul to use with his new 66' dbl end Cannon bar and chainsaw-mill. According to the dealer who talked to me (and has ordered more Meteor kits for his shop from me since then). One saw needed a coil and a good cleaning and the other had a slight leak at the cylinder gasket. The first saw took to the cylinder swap like a champ and ran well and tached properly from the get go. The second saw he said the piston felt tight in the bore on the new kit , but since he was still able to spin it in the cylinder he went ahead and reassembled the saw. During the initial tuning he said the saw acted funny and ran rough, so he shut it down after taching to 13, 000RPM and checked the piston through the exhaust and found the beginning of markings already within a minute or two of run time out of the wood.

I have seen some scored P/C in the past (maybe 100s by this point), but this seems odd. He said the circlips were installed properly and he used new OEM piston bearings. I sent a new kit out ASAP and Meteor immediately said they would send me an extra kit for free in this weeks order. New kit is installed and customer happy. The dealer told the customer subsequently that he spent a couple of hours working the top of the crankcase on a marble slab to get it true before installing the second new jug. I bought the two 064 p/c from the original customer and one of the jug shows similar marks on the piston, they are purely optical, nothing you can feel at all and on the OEM ringset there are no marks or scratches. On the Caber rings from the Meteor piston there are distinct tiny scratches. The original cylinders are both perfect no marks even. This cylinder has marks like the piston but again nothing you can feel.

To me it doesn't look like bad gas or traditional lean condition or piss revving and no sign of carbon on any ports. I am very curious as to what this might be. Tech said he thought bad plating on cylinder of new cylinder but that doesn't sit right in my head. Not looking to blame anybody, just gain a better understanding.

Yeah pics.

DDave

Details for the enlightened: About 3 weeks ago a customer bought a pair of Meteor MS660 / 066 cylinder kits from me and took his pair of older 064AV saws to his Stihl dealer for overhaul to use with his new 66' dbl end Cannon bar and chainsaw-mill. According to the dealer who talked to me (and has ordered more Meteor kits for his shop from me since then). One saw needed a coil and a good cleaning and the other had a slight leak at the cylinder gasket. The first saw took to the cylinder swap like a champ and ran well and tached properly from the get go. The second saw he said the piston felt tight in the bore on the new kit , but since he was still able to spin it in the cylinder he went ahead and reassembled the saw. During the initial tuning he said the saw acted funny and ran rough, so he shut it down after taching to 13, 000RPM and checked the piston through the exhaust and found the beginning of markings already within a minute or two of run time out of the wood.

I have seen some scored P/C in the past (maybe 100s by this point), but this seems odd. He said the circlips were installed properly and he used new OEM piston bearings. I sent a new kit out ASAP and Meteor immediately said they would send me an extra kit for free in this weeks order. New kit is installed and customer happy. The dealer told the customer subsequently that he spent a couple of hours working the top of the crankcase on a marble slab to get it true before installing the second new jug. I bought the two 064 p/c from the original customer and one of the jug shows similar marks on the piston, they are purely optical, nothing you can feel at all and on the OEM ringset there are no marks or scratches. On the Caber rings from the Meteor piston there are distinct tiny scratches. The original cylinders are both perfect no marks even. This cylinder has marks like the piston but again nothing you can feel.

To me it doesn't look like bad gas or traditional lean condition or piss revving and no sign of carbon on any ports. I am very curious as to what this might be. Tech said he thought bad plating on cylinder of new cylinder but that doesn't sit right in my head. Not looking to blame anybody, just gain a better understanding.

Yeah pics.

DDave