headleyj

ArboristSite Guru

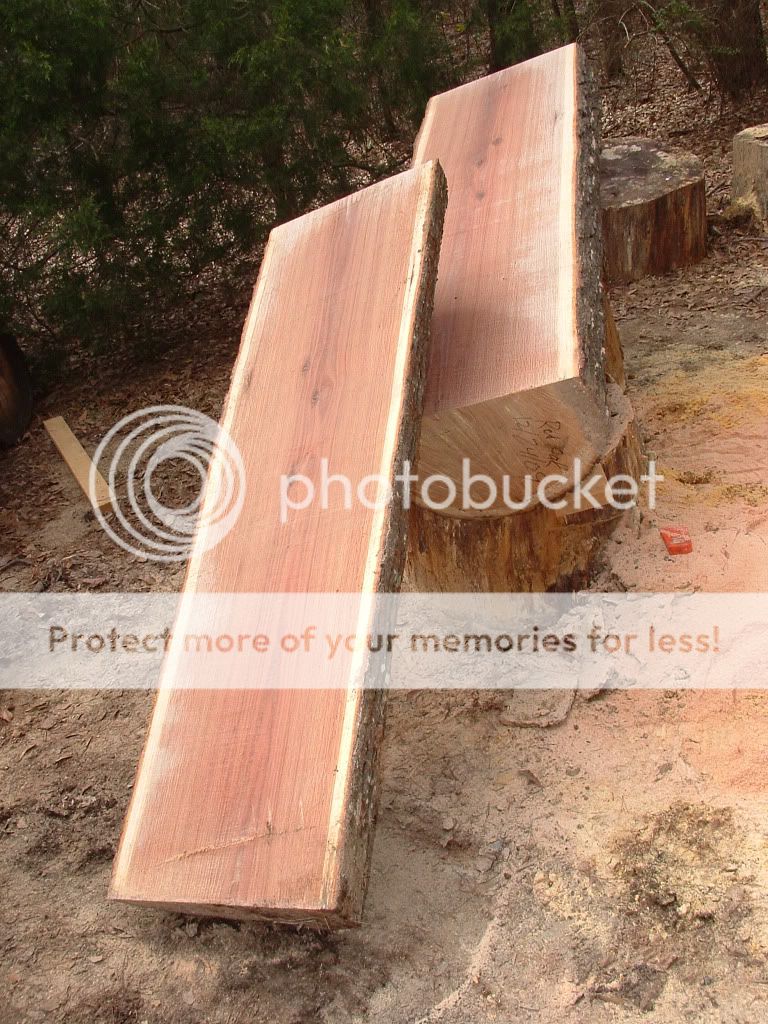

Well I finaly got time to put the 395 on the mill and try it last night. Worked well. Not as easy as I thought, but the satisfaction was GREAT seeing a 2"x 12' red oak board come from a tree on our place.

No pics yet - wife took the dang camera.

Setup- 36" Granberg Alaskan...395xp w/ 36" b/c....oregon ripping chain (dealer ground to 10° for me)

Observations:

- Gotta get the log up higher for sure....it was only ~1' off the ground.

- Used 1/2 of my 22' extension ladder as top rails - think it would slide easier with Delrin attached to it and the mill.

- Was real tough to push mill on 2nd cut.

- Oak log was ~12' long....20" on one end (fork in tree) & ~12" on other

- Beautiful grain especially in crotch wood

Question:

- When the saw is pulling itself into the wood, it was tough to push it through I thought, especially on 2nd cut.....tougher than I expected any way.....finesse of pushing on the mill helps I'm sure, just couldn't seem to find that sweet spot.....is this just the way it is?

Now I gotta get more tools to build the outdoor furniture wifey wants

No pics yet - wife took the dang camera.

Setup- 36" Granberg Alaskan...395xp w/ 36" b/c....oregon ripping chain (dealer ground to 10° for me)

Observations:

- Gotta get the log up higher for sure....it was only ~1' off the ground.

- Used 1/2 of my 22' extension ladder as top rails - think it would slide easier with Delrin attached to it and the mill.

- Was real tough to push mill on 2nd cut.

- Oak log was ~12' long....20" on one end (fork in tree) & ~12" on other

- Beautiful grain especially in crotch wood

Question:

- When the saw is pulling itself into the wood, it was tough to push it through I thought, especially on 2nd cut.....tougher than I expected any way.....finesse of pushing on the mill helps I'm sure, just couldn't seem to find that sweet spot.....is this just the way it is?

Now I gotta get more tools to build the outdoor furniture wifey wants