Daninvan

ArboristSite Operative

Over the holidays I had planned to add wheels and a nose guard to each of my three Alaska mills. Also to buy a pair of chaps.

Well the holidays are nearly over and I have managed to accomplish 1/3 of one task. I added wheels to one of my mills.

I noticed that all the other wheels that I saw on this site were adjustable in the vertical direction. I considered a bunch of ways to do this, then decided to try wheels that were adjustable in the horizontal direction. Mostly because I didn't have anything handy and vertical on the mill to mount the wheels to. But also I wanted to keep the wheels close to the rails as I thought it would minimize any torque.

I made little 'wings' out of ipe, cut out a long slot in each, then mounted them to the side of the mill. I bolted a couple old rollerblade wheels into the slots and I am ready to go.

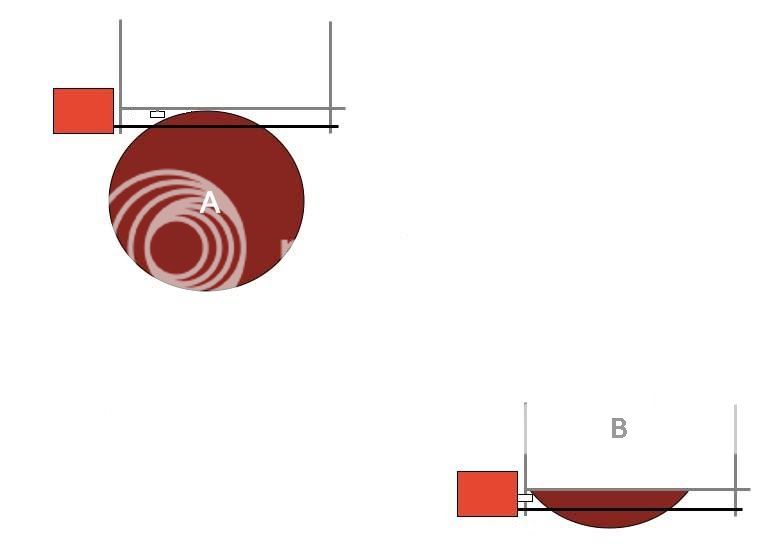

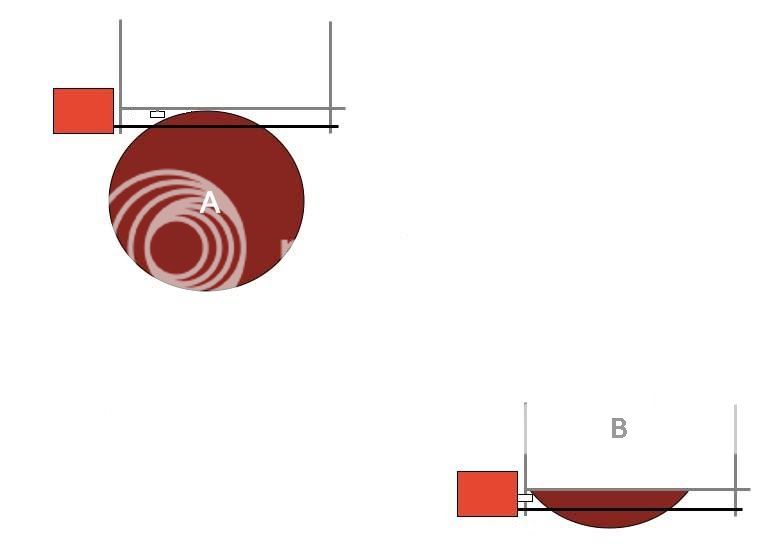

So now the idea is that I can move the wheels along the slots so they ride on the edge of the log, as shown in the drawing below that I adapted from BobL.

In practice (which is going to be a couple weeks still) I figure that most of the time they will be left in place a couple inches in, say where they are now more or less ('A'), and need to be moved out to give maximum cutting width ('B') only on those few occasions I am cutting at the max width my mill can handle. I can see a bit of tweaking needed already, my slots need to extend behind the mill (up in the first photo) a couple inches more to avoid losing cut width in position B.

Cheers and Happy New Year to All! I look forward to ogling everybody's milling pictures in 2010!

Dan

Well the holidays are nearly over and I have managed to accomplish 1/3 of one task. I added wheels to one of my mills.

I noticed that all the other wheels that I saw on this site were adjustable in the vertical direction. I considered a bunch of ways to do this, then decided to try wheels that were adjustable in the horizontal direction. Mostly because I didn't have anything handy and vertical on the mill to mount the wheels to. But also I wanted to keep the wheels close to the rails as I thought it would minimize any torque.

I made little 'wings' out of ipe, cut out a long slot in each, then mounted them to the side of the mill. I bolted a couple old rollerblade wheels into the slots and I am ready to go.

So now the idea is that I can move the wheels along the slots so they ride on the edge of the log, as shown in the drawing below that I adapted from BobL.

In practice (which is going to be a couple weeks still) I figure that most of the time they will be left in place a couple inches in, say where they are now more or less ('A'), and need to be moved out to give maximum cutting width ('B') only on those few occasions I am cutting at the max width my mill can handle. I can see a bit of tweaking needed already, my slots need to extend behind the mill (up in the first photo) a couple inches more to avoid losing cut width in position B.

Cheers and Happy New Year to All! I look forward to ogling everybody's milling pictures in 2010!

Dan