JakeG

Addicted to ArboristSite

This will be on-going documentation as I try my hand at milling.

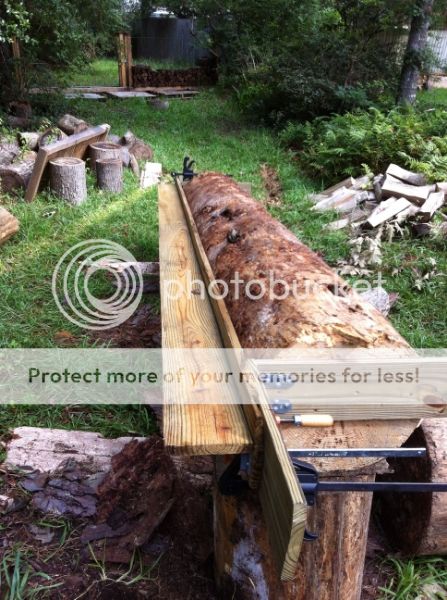

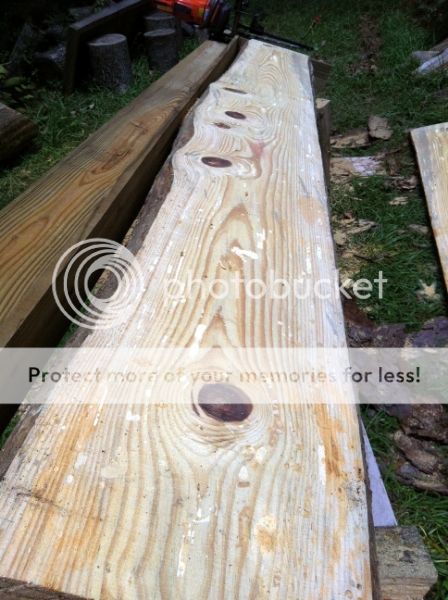

I started out with a 10" diameter x 8' 6" long Red Oak, the Logosol Timberjig & my Husqvarna 562xp. The bar nuts on this saw are retained into the cover via 3 metal clips per nut. I removed them and used nuts from another saw. I went with a small 16" bar and had to use full chisel oregon chain. The Woodland Pro/Carlton ripping chain I ordered went on back order.

This is a temporary set up, no doubt. In the future I will use aluminum profile to make my own Alaskan style mill.

Here's the story in picture & video:

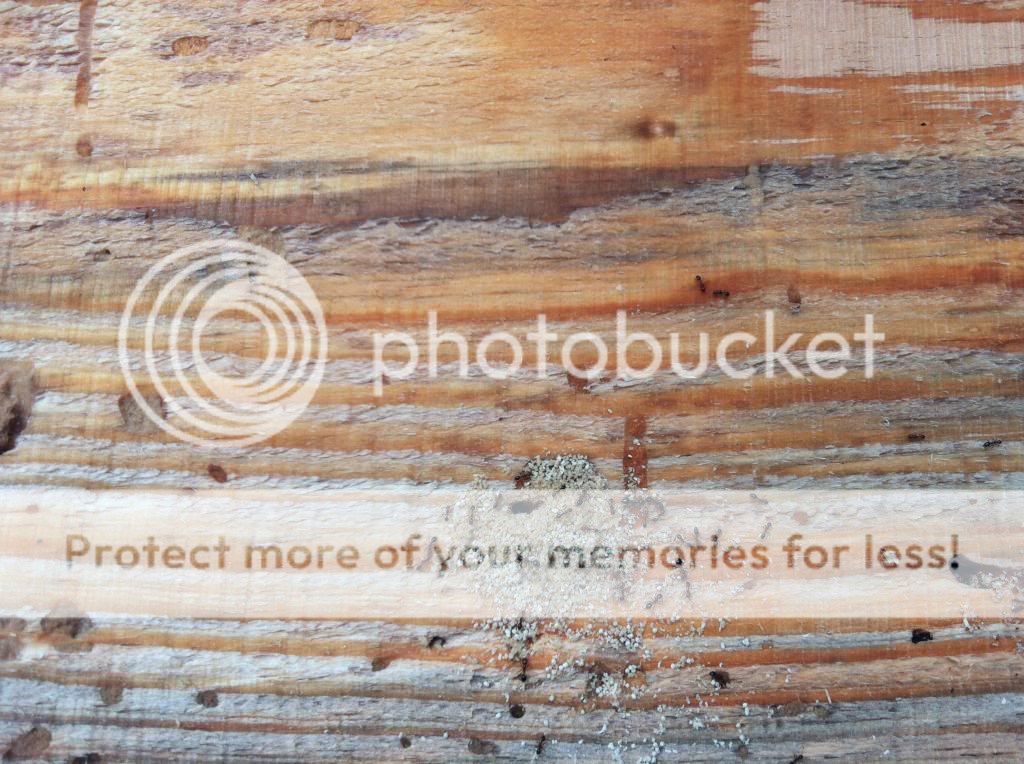

Here's a video of my first piece of lumber. I'm beyond happy I took this video as it provided me with instant feedback and an opportunity to learn from my mistakes/nip bad habbits in the bud. There were several "mistakes" right off the bat... Let's see if you can name them! opcorn:

opcorn:

[video=youtube_share;0CnHUXQTZzo]http://youtu.be/0CnHUXQTZzo[/video]

I started out with a 10" diameter x 8' 6" long Red Oak, the Logosol Timberjig & my Husqvarna 562xp. The bar nuts on this saw are retained into the cover via 3 metal clips per nut. I removed them and used nuts from another saw. I went with a small 16" bar and had to use full chisel oregon chain. The Woodland Pro/Carlton ripping chain I ordered went on back order.

This is a temporary set up, no doubt. In the future I will use aluminum profile to make my own Alaskan style mill.

Here's the story in picture & video:

Here's a video of my first piece of lumber. I'm beyond happy I took this video as it provided me with instant feedback and an opportunity to learn from my mistakes/nip bad habbits in the bud. There were several "mistakes" right off the bat... Let's see if you can name them!

[video=youtube_share;0CnHUXQTZzo]http://youtu.be/0CnHUXQTZzo[/video]