buildmyown

ArboristSite Operative

I have a woodstove that is dated 1979 unsure of the brand maybe some of you can ID it for me. This stove has served us great for the last 30 years. Its in the basement and has no problem heating 1800+sf of living space upstairs not including the basment in a raised ranch so I really dont want to replace it. The stove itself is solid the pictures make it look rougher then it is.

Now to my problem I noticed last season that what im going to call a draft diverter you can see it in the second pic its the piece of 1/4 steel thats warped and rotted out. I know that this is causing me to loose some heat output from the stove right up the pipe. I would like to replace this part but there is no way to remove it in one piece. It is only held in with two pieces of angle iron and a couple of bolts. I already got those out. I im assuming that this part was put in before the top was welded on at the factory.

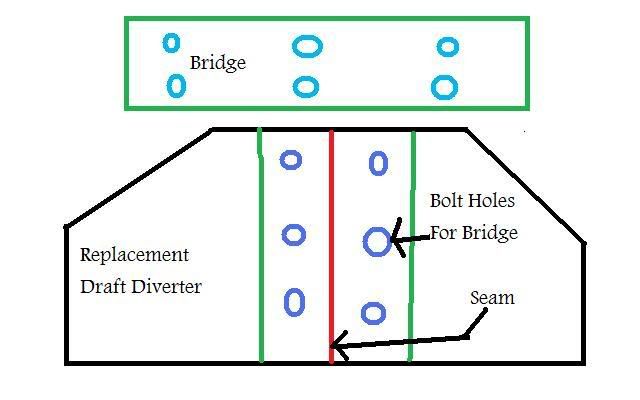

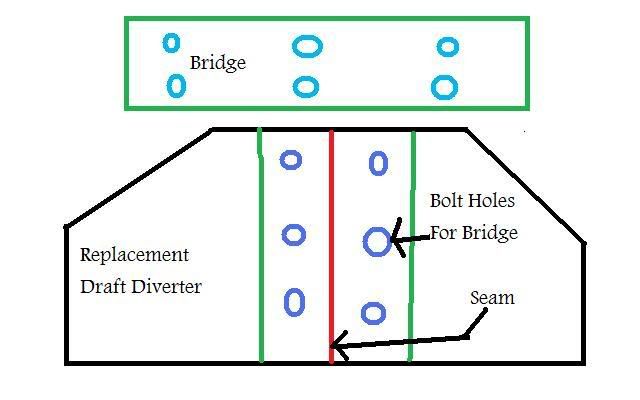

My plan is to cut it in half with a sawzall and make a template from cardboard and have a local metal shop cut my a new piece. To install the new piece I was going to have them cut the piece in half and drill a series of holes along the seam and have them make me a bridge with the same series of holes. The plan is to get the two new pieces in the stove and bolt them together using the bridge. The other idea I had was to cut the new part in half and just weld it back together once I have both parts in the stove.

Ideas, comments and concerms please.

Here are a few pics. Pic one is ove the whole stove, Pic two shows the part I want to replace and pic three is a rough drawing of the replacement.

Now to my problem I noticed last season that what im going to call a draft diverter you can see it in the second pic its the piece of 1/4 steel thats warped and rotted out. I know that this is causing me to loose some heat output from the stove right up the pipe. I would like to replace this part but there is no way to remove it in one piece. It is only held in with two pieces of angle iron and a couple of bolts. I already got those out. I im assuming that this part was put in before the top was welded on at the factory.

My plan is to cut it in half with a sawzall and make a template from cardboard and have a local metal shop cut my a new piece. To install the new piece I was going to have them cut the piece in half and drill a series of holes along the seam and have them make me a bridge with the same series of holes. The plan is to get the two new pieces in the stove and bolt them together using the bridge. The other idea I had was to cut the new part in half and just weld it back together once I have both parts in the stove.

Ideas, comments and concerms please.

Here are a few pics. Pic one is ove the whole stove, Pic two shows the part I want to replace and pic three is a rough drawing of the replacement.