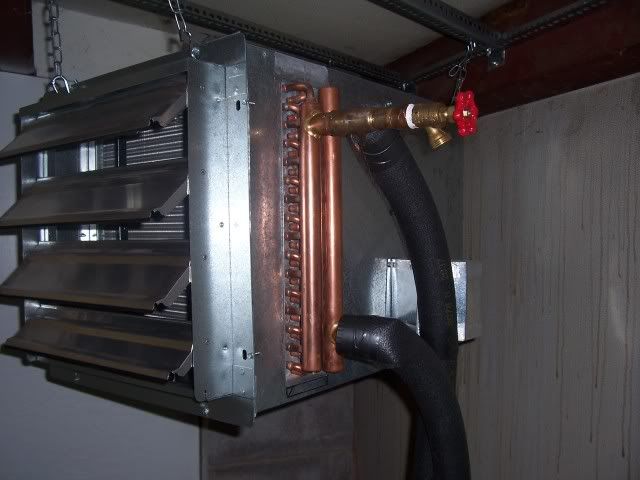

I'm using both outputs on my CB 5036, one to shop is up and running, hopefully house this weekend, both setups use water to air exchangers. Shop hanging heater is highest point in system, boiler drain on top seems to purge out air easy enough. First question...should I have to keep purging air out of that? It's only been running a week but seems like every day I can purge out a bit of air, is that normal? I don't have any leaks that I can find but it seems to me I shouldn't keep getting air, maybe I just don't have it all yet?

Second question is the house....the lines to the house a bit different that most...goes into my shop, up about 14ft, across a 40ft I-beam, down 14 feet again then out the building and underground 100ft to house....inside the house my side arm exchanger will be the highest point but the 14ft up and over the Ibeam is technically the highest point in the system but it's a seamless run of pex up and over the shop...my question is purging air....after hooking up my shop I know I'll have air to purge...but where? Top of side arm? That would be easiest but my fear is air will end up in the shop over my Ibeam 14ft up...will I even know it's trapped? I could put a T up there with a vertical stub and boiler drain but I'd rather not...that would certainly be highest point though....even then which line needs it, both or will it make it's way to which ever line has the T and stub? My furnace water to air coil is lower than my side arm...shouldn't be any need to purge there correct?

Maybe I'm overthinking and should just hook it up?

Second question is the house....the lines to the house a bit different that most...goes into my shop, up about 14ft, across a 40ft I-beam, down 14 feet again then out the building and underground 100ft to house....inside the house my side arm exchanger will be the highest point but the 14ft up and over the Ibeam is technically the highest point in the system but it's a seamless run of pex up and over the shop...my question is purging air....after hooking up my shop I know I'll have air to purge...but where? Top of side arm? That would be easiest but my fear is air will end up in the shop over my Ibeam 14ft up...will I even know it's trapped? I could put a T up there with a vertical stub and boiler drain but I'd rather not...that would certainly be highest point though....even then which line needs it, both or will it make it's way to which ever line has the T and stub? My furnace water to air coil is lower than my side arm...shouldn't be any need to purge there correct?

Maybe I'm overthinking and should just hook it up?