gr8scott72

Addicted to ArboristSite

I can't see how you get anywhere close to 400 lbs for that size.

If its 53" at one eld and 40 at the other that's an average of 46.5" wide

Volume is then 46.5"/12 x 6' x 2"/12 = 3.875 cuft

The density of green red oak is at most about 50 lbs/cuft.

So that makes it about 200 lbs

Even if it was lemon scented gum (density of 71.8 lb/cuft) it would still only weigh 279 lbs

It sounds like either the wood is dirty or the chain is not set up right?

With a freshly sharpened chain I get about 36 sqft of cut (eg 9 x 4 ft) with one tank of fuel on the 880 in wood that will be as hard or harder than than red oak.

If I do not have a freshly sharpened chain for every cut I will need 1.5 - 2 tanks to cut the same area. Cutting with a less than freshly sharpened chain also places a significantly greater load on the engine, I can see the temperature increase significantly 20 up to 40F over my usual milling temp

I guess you're right but this sure seems like more than 200 lbs. It was all I could do to pick up one end of it.

The chain was freshly sharpened and was cutting just fine. It didn't take any extra pressure and was still throwing sawdust and small curly chips out by the boat loads. (OK, not quite boatloads but it was a big mound.)

The wood isn't dirty and I don't think I hit anything in it. I'll put a good edge back on it tomorrow and try another one.

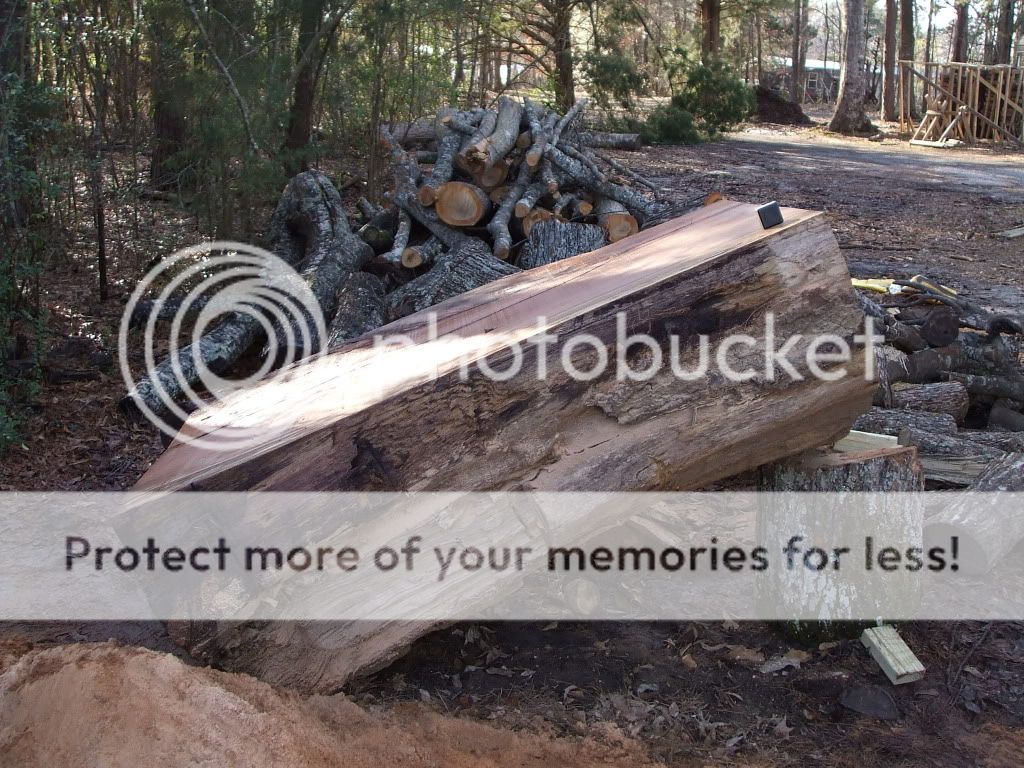

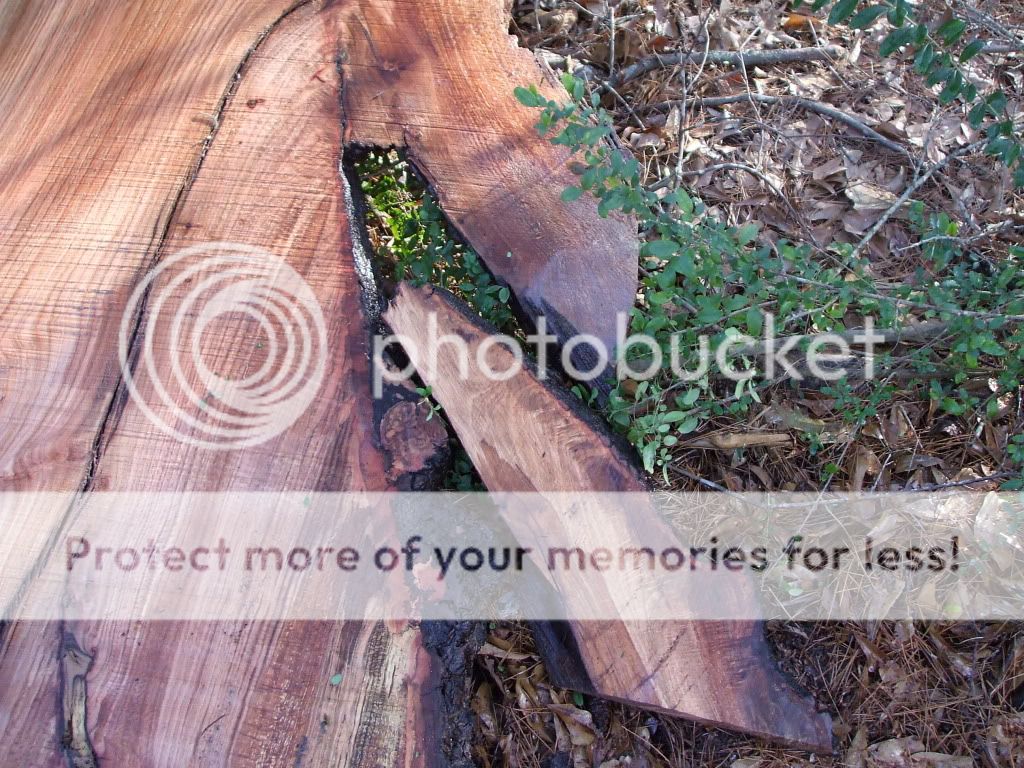

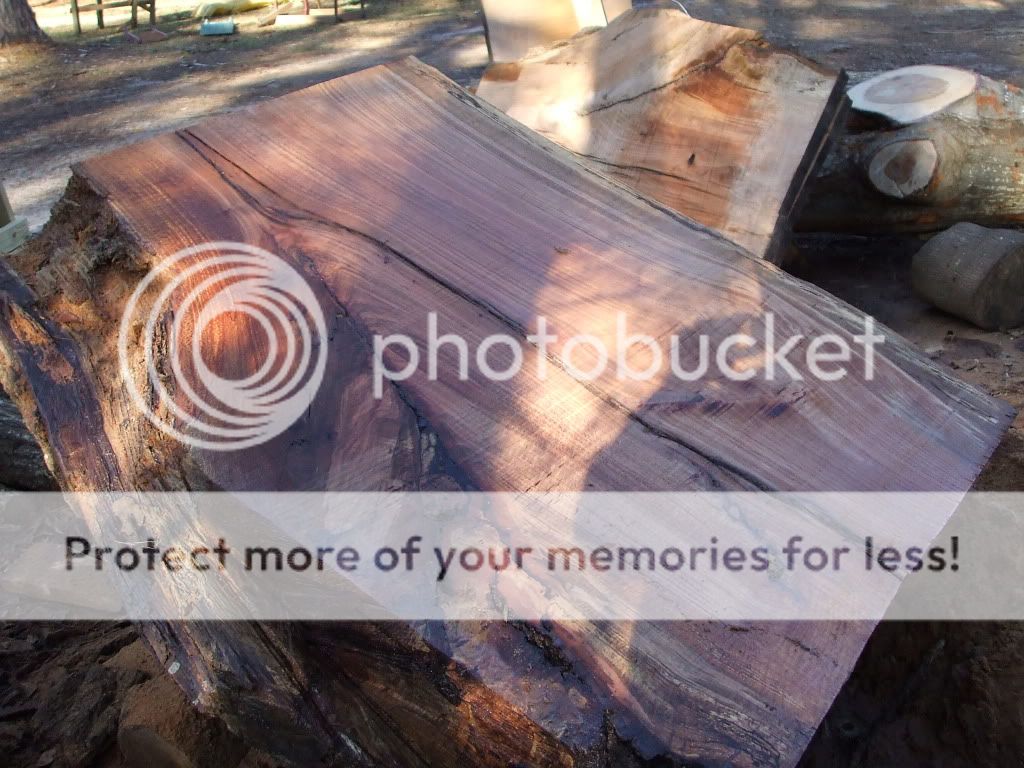

You will appreciate these pictures Bob: