We bought a bunch of Bee line to make VT friction hitches with, but NOBODY wants to tell me how to splice it. Not Sherrill, they will splice it for you, but they won't tell you how to do it for yourself. Yale Cordage won't either, and they made the stuff.

I have concluded that it should be a core dependant class II splice, but I suspect that I should be real careful to get the exact instructions for this application.

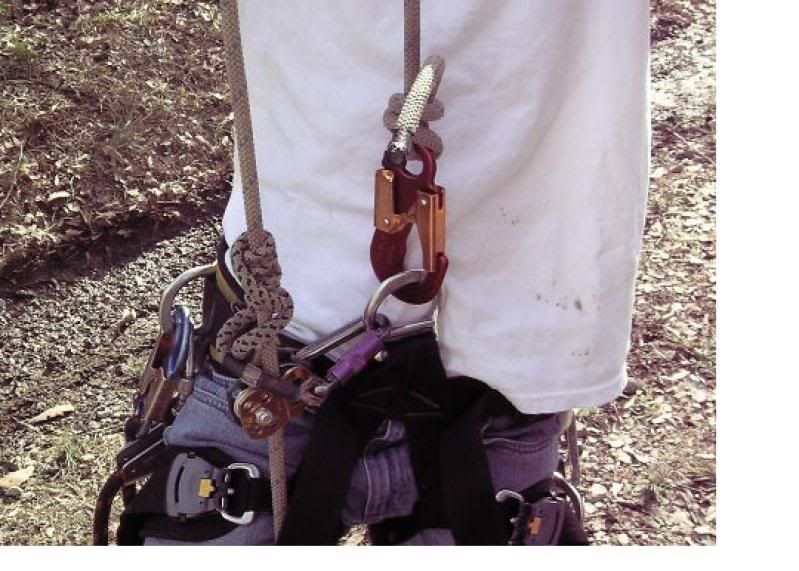

Right now we are using double fisherman's knots, but it would be nice to be a little more streamlined.

I have concluded that it should be a core dependant class II splice, but I suspect that I should be real careful to get the exact instructions for this application.

Right now we are using double fisherman's knots, but it would be nice to be a little more streamlined.