flashhole

Addicted to ArboristSite

If you saw my other thread you know I was fighting a large Ash tree that was knocked over by a storm. I cut it up into sections and pulled it down from the other trees it was hung up in (chapters 1-4). Today started off as a rainy day, it let up and I went to the woods to see if I could make any progress skidding the big logs up from the ravine with my 30 HP tractor. I no sooner started work in the woods and it started to rain again. At least it was cooler but I still sweat like a pig. It was about 1/2 mile from the tree to the milling station. Didn't have a camera with me in the ravine.

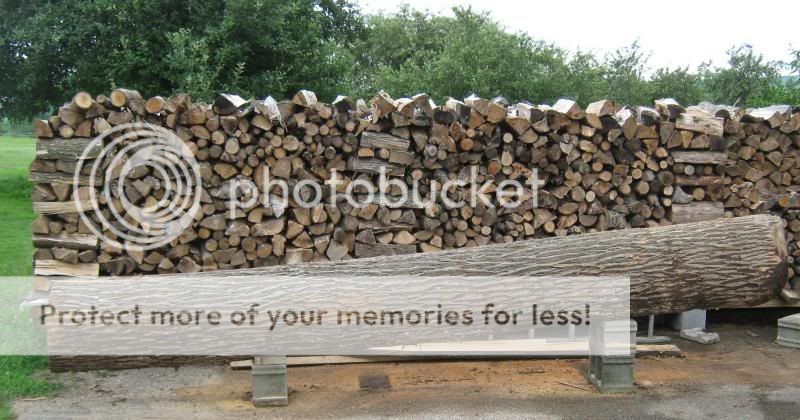

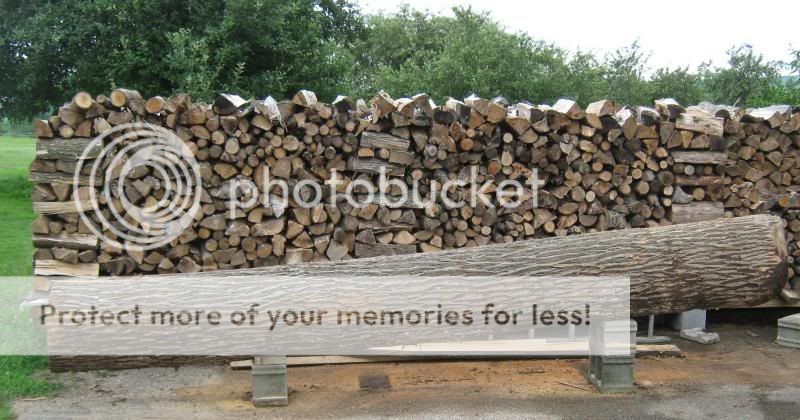

Snake trail to the milling site.

This is the first of 4 sections I need to pull out of the ravine. It was a LOT of work to get this puppy up to the asphalt pad. It took about 3 hours but I got it done. The plan is to mill 4 beams from this log for a horse shelter. I will post other pics of the progress.

Snake trail to the milling site.

This is the first of 4 sections I need to pull out of the ravine. It was a LOT of work to get this puppy up to the asphalt pad. It took about 3 hours but I got it done. The plan is to mill 4 beams from this log for a horse shelter. I will post other pics of the progress.

Last edited: