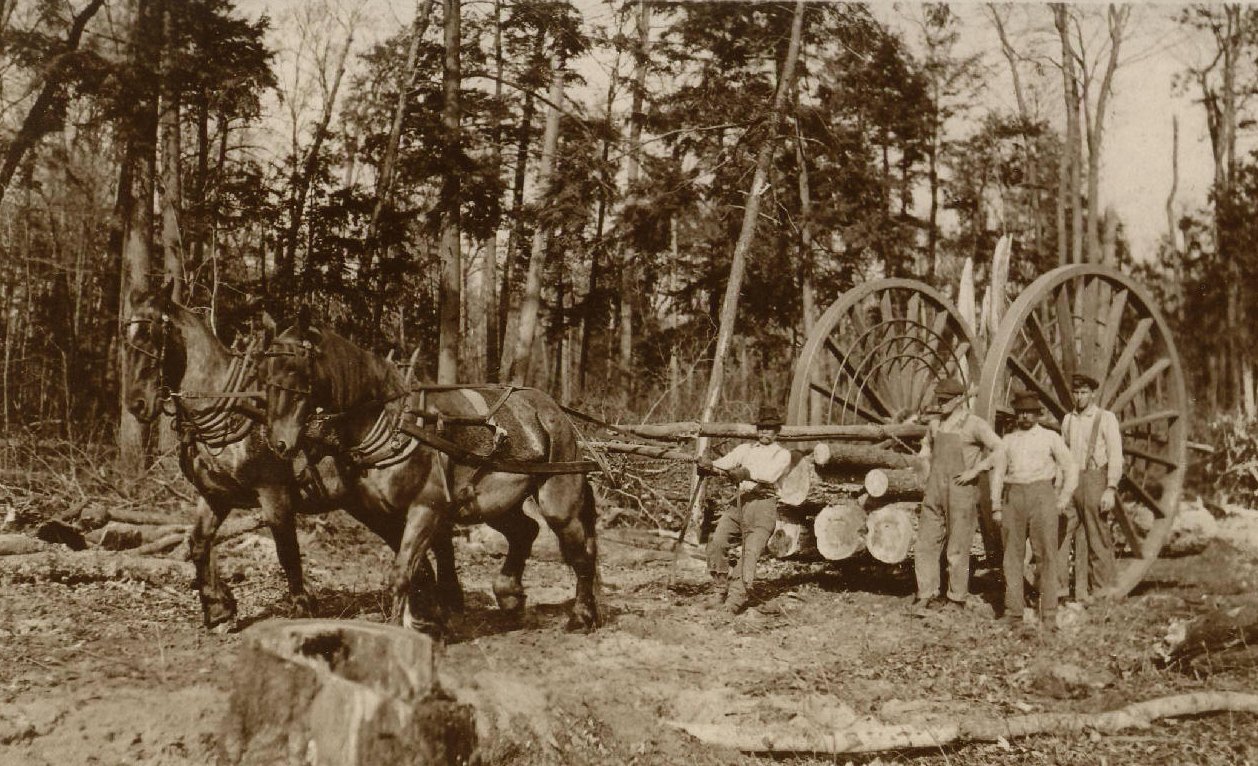

Has anybody made or know of anything to assist with moving slabs by hand. I'm thinking of something somewhat similar to this system for pulling kayak's etc: http://www.muletransportsystems.com/

I'm hoping to get bigger slabs so not looking at trying to move a whole log.

I'm still working through a system so I can get some slabs out of the state forest down the road (but no vehicles allowed). I've got some pieces to practice on that I can't get a vehicle to on my lot.

I'm hoping to get bigger slabs so not looking at trying to move a whole log.

I'm still working through a system so I can get some slabs out of the state forest down the road (but no vehicles allowed). I've got some pieces to practice on that I can't get a vehicle to on my lot.