Mine runs fine, but I assure you it does not push 250 psi compression. Heck, if it did that, I'd never be able to start it without a decomp valve. Give me a running Stihl 026 saw, a sharp chain, a bunch of hardwood firewood logs, and a truck to haul it away. That usually works.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

024 to 026?

- Thread starter a. palmer jr.

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

The 026 I have I never was really satisfied with it, just doesn't run like I think it should. As an example I own a MS250 that I think will cut circles around the 026. The 026 has a new P/C so the compression should be okay and I did check all the rubber parts when it was apart and I put a new clutch side seal on the crank but haven't gotten around to the other side yet. I looked at the seal on the flywheel side some time ago and it looked okay to me but it may have a leak, certainly wasn't oily on that side though..

My only complaint with my 026 PRO is the same one I have with my 361. It usually always starts, but a cold start takes 4 to 5 pulls to do it -- two or three on choke and then two more on fast idle. But, they always start and run well, and that's what counts.

I brought in four truckloads of hardwood this past week, working mostly from 7 to 10 am. The heat right now is brutal, so morning hours are a must. The 026 PRO did almost all of it with a 16" bar and using one sharp chain that I must now sharpen. When you don't hit the ground, the cutters last and last.

I brought in four truckloads of hardwood this past week, working mostly from 7 to 10 am. The heat right now is brutal, so morning hours are a must. The 026 PRO did almost all of it with a 16" bar and using one sharp chain that I must now sharpen. When you don't hit the ground, the cutters last and last.

redunshee

Addicted to ArboristSite

I have both a Ms 260 18" bar and an 024 16" bar. I swear the 024 runs almost as good as the 260. Maybe a 2" longer bar make a difference?

That 18" bar does make a difference. I noticed it awhile back, especially on an 025 that seem to struggle with an 18" bar. With .325 chain on both, the 025's 18" bar actually has only one more drive link that the 026's 16" bar. A new chain loop with 68 drive links will actually work with the 026's 16" bar until it stretches too far. I have an 18" bar for the 026, but I seldom use it, preferring instead to move up to a larger saw, such as the 028.I have both a Ms 260 18" bar and an 024 16" bar. I swear the 024 runs almost as good as the 260. Maybe a 2" longer bar make a difference?

On my MS250 I use a 16" bar and a 3/8 LP chain and it really works great for that saw.

One of the 025's that I sold was outfitted the same way with 3/8 LP chain. The owner says it's the best chain saw he has ever run. I offered to buy it back for what he paid for it. He said, "No entire way. It's mine now."On my MS250 I use a 16" bar and a 3/8 LP chain and it really works great for that saw.

I received my P/C today, installed it today and got it running, probably still needs the carb cleaned but I have a question..Why do these P/C kits only have two circlips in them? I would think 6 would be more appropriate...good thing I keep a few spares around.

Three reasons: Cost cost cost. I have about a dozen now because the ones I take off the old piston/rod usually can be used again. I agree that it's a bit rough to find them after they flip off and fly across the shop. BTDTI received my P/C today, installed it today and got it running, probably still needs the carb cleaned but I have a question..Why do these P/C kits only have two circlips in them? I would think 6 would be more appropriate...good thing I keep a few spares around.

My shop has so much junk that I knew one was lost as soon as I heard the noise. I briefly looked on the floor but I figured it was in a pile of junk under a table or something. I could clean the place up if I had a spare five years or so..I ended up using a couple of Stihl take offs.

Guess what, I was messing around the shop today and found the missing circlip right in the middle of the floor! I went ahead and installed 2 used ones thinking I could never find the little bugger and there it was! I'll keep it for a spare along with the other new one..I'll probably need it.

Guess what, I was messing around the shop today and found the missing circlip right in the middle of the floor! I went ahead and installed 2 used ones thinking I could never find the little bugger and there it was! I'll keep it for a spare along with the other new one..I'll probably need it.

It's been quite a day...remember I said I was a bit disappointed by how my 026 ran? I felt the same way with my 024 when I got it together, running but not great. well I remembered I didn't clean the carburetor so I did that this morning and it really helped, so I did the same thing to my 026 and found the carburetor really filthy and corroded inside so I got a different carb for it and cleaned it also and put a new kit in it and it really brought the 026 to life! I also had to do that to a 025 I'm working on today and now it's ready to go. Hopefully tomorrow will be a true retirement day.

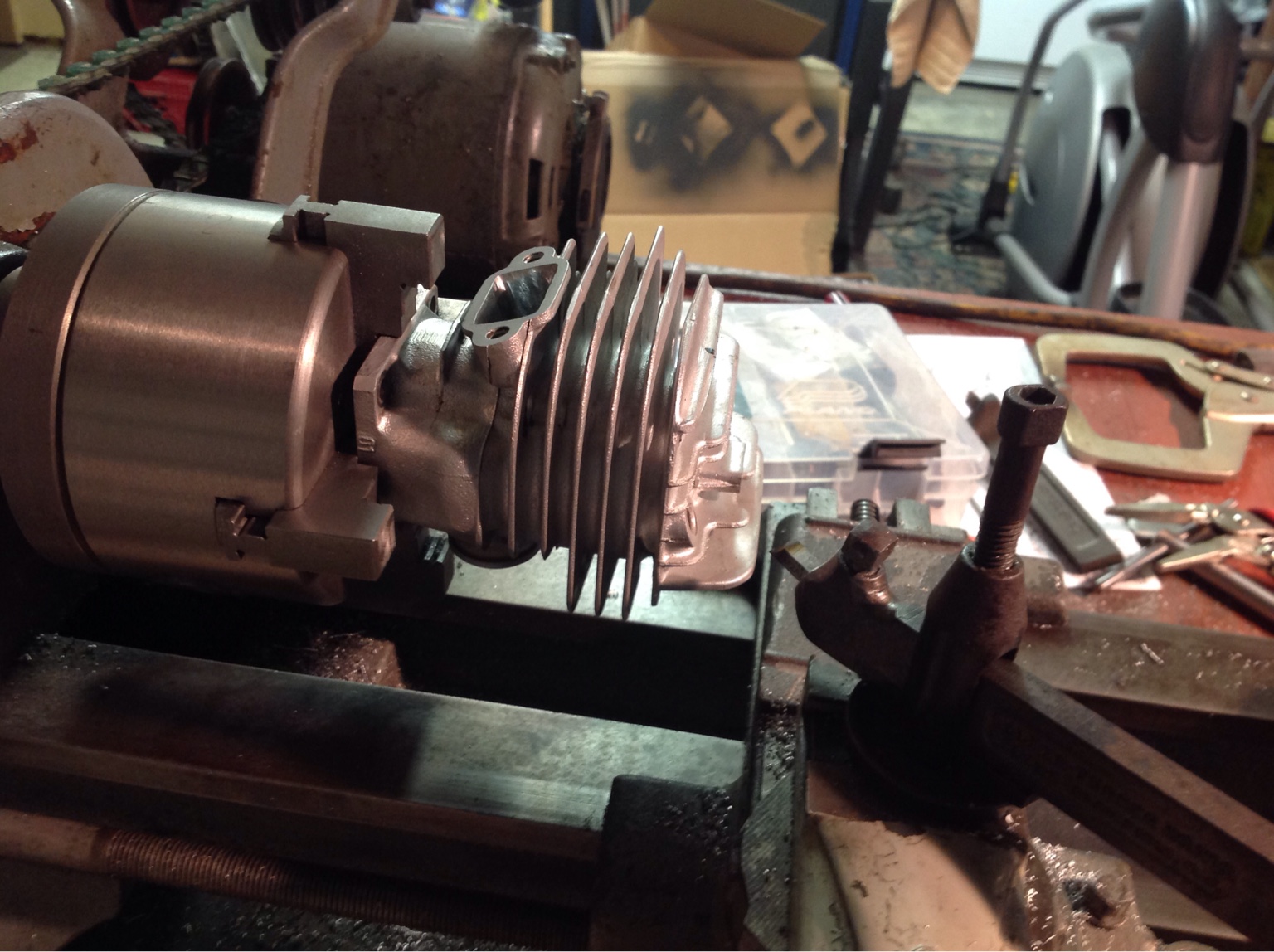

I know this is an old post but I'm having trouble finding a made in japan 026 flywheel for my o24avs that I'm putting an 026 p/c on, any ideas?An 026 P&C will fit an 024 SUPER just fine, but you need to cut off a few cooling fins on the top of the jug to make it do so. The height of the jug is taller on the 26. If you don't cut the fins, you will have to use 026 plastics, both top and rear (If you want it to look nice).

The flywheel should really be changed on the 024 if you step up the displacement or performance. The Japanese built Stihl 026 flywheel is a huge cooling improvement over the 024 German one.

I'm still going to try an 026 jug on a Non-Super 024. The above poster is right about the different stroke. What people don't understand is that the crank is set higher in the case in the regular 024. When they made the super, they dropped where the crank centerline was. I suspect that was 1mm. My suspicion is that the piston at TDC height is likely the same on both the non-super and super 024, but I still need to confirm this. The shorter stroke may actually help the timing numbers on the OEM jug as well.

There's a build thread on the forbidden site of an 024S to 026 jug ported conversion.

Outdoor power equipment forum. This site won't allow me to post the link.

drf255

BAD CAD

Any 026 flywheel should be the one you want.

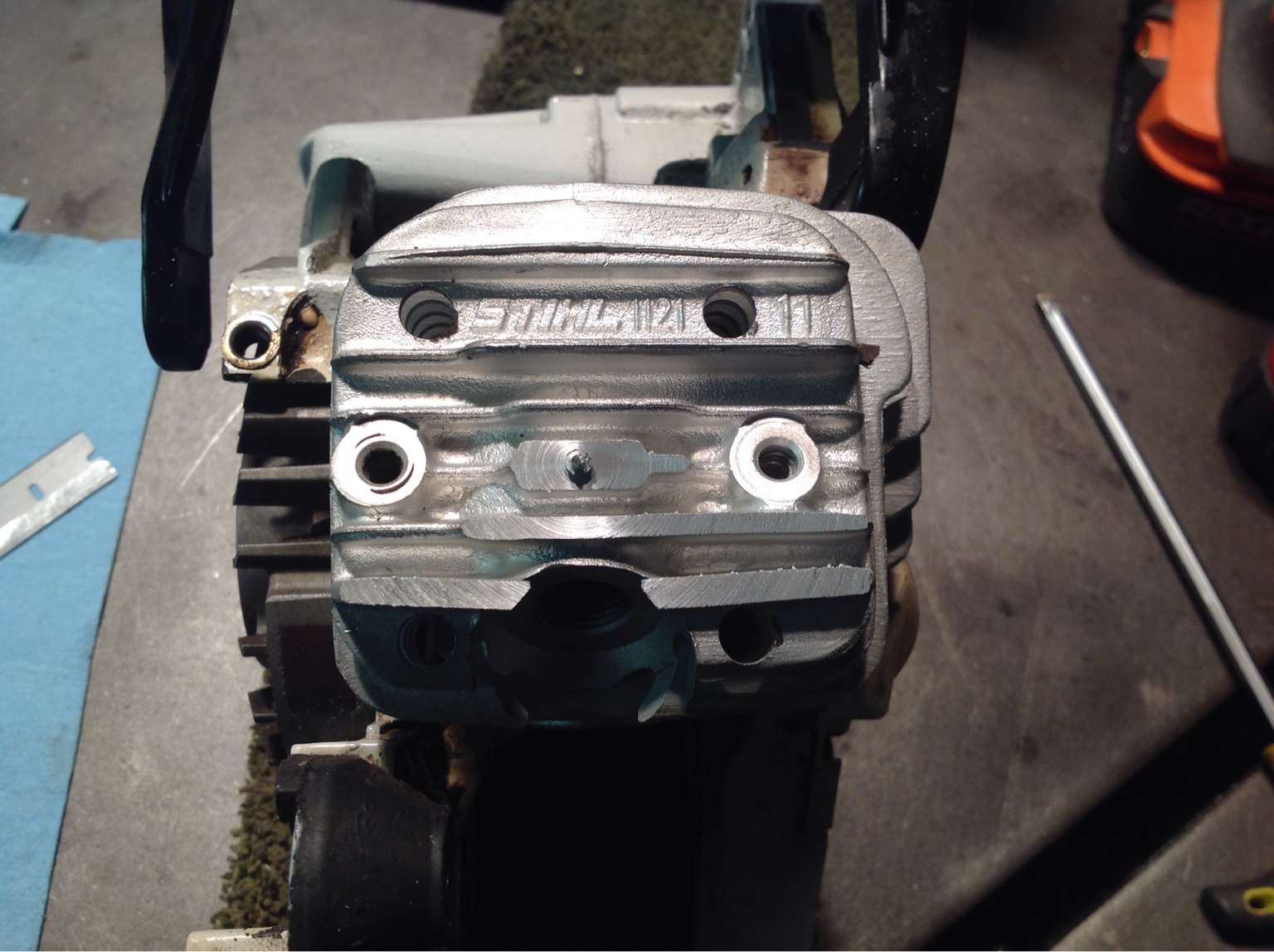

Nice clean job. That's a killer 024. That sleeper can ruin some egos with 250 psi and 17500 rpms. What have you done to it?

Sent from my iPad using Tapatalk

Sent from my iPad using Tapatalk

Similar threads

- Replies

- 1

- Views

- 344

- Replies

- 6

- Views

- 764