Picked up this well used and very blown up 562xp last year. I really wanted to see what all the fuss was about and at a price of $100 CAD I figured I couldn't go wrong..

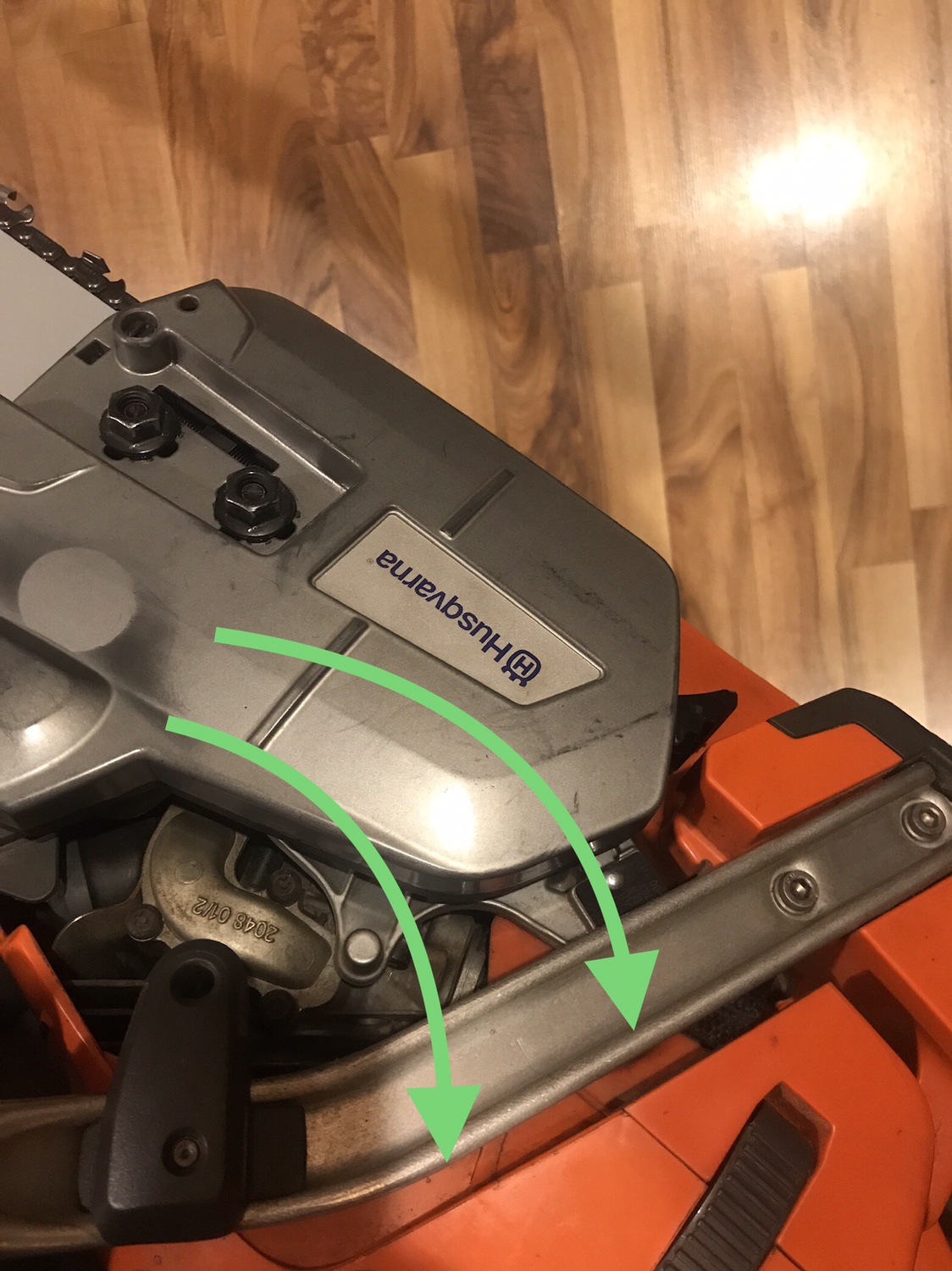

Heres the saw when I started, filthy but complete.

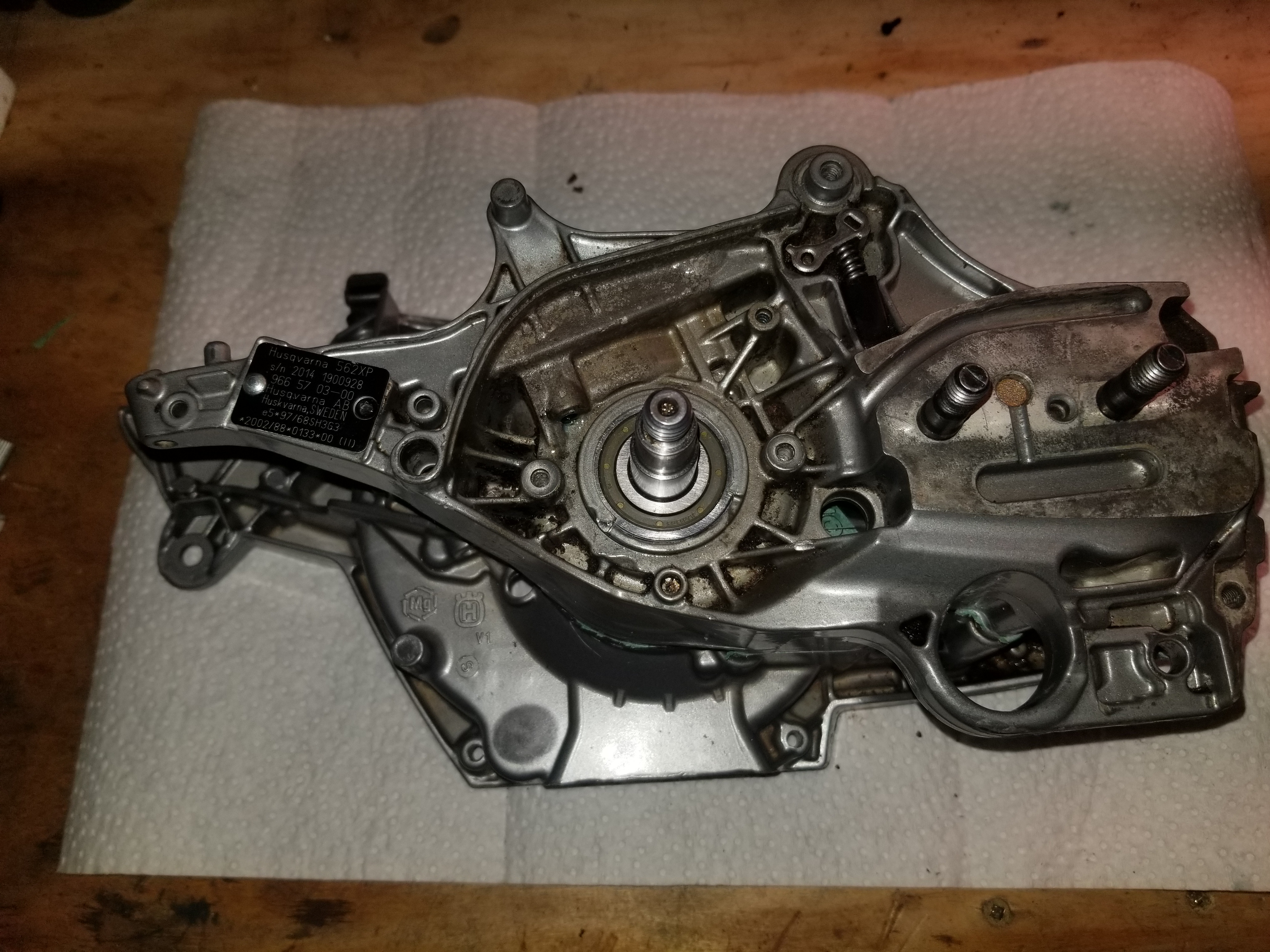

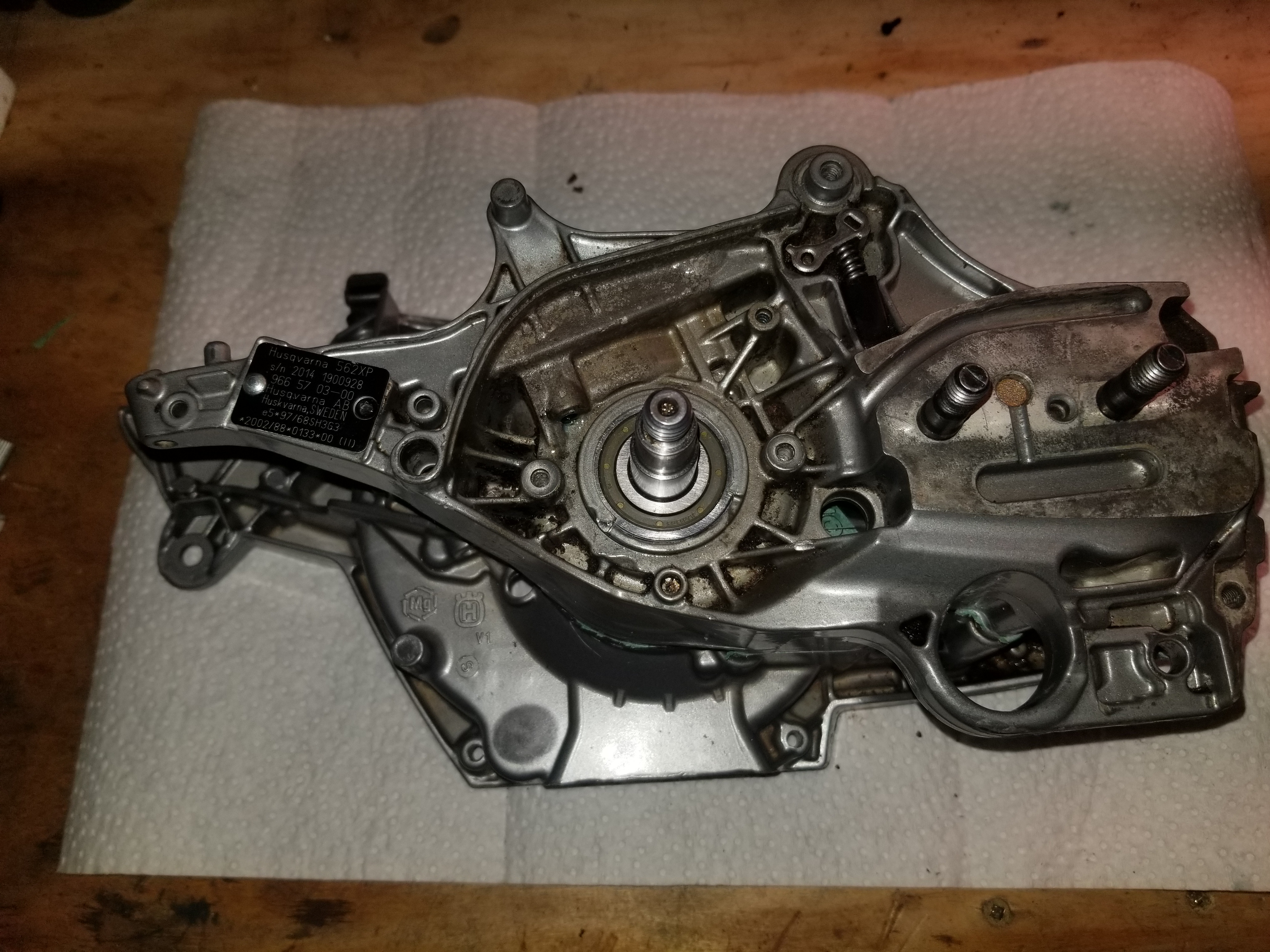

After some cleaning I came to find out it was a 2014 model with an EL-48 carb and a 6 screw case..

The saw failed both vac and pressure tests so I started tearing it down.

Pulled the flywheel and found this.

Bottom of the seal was completely gone.

Other side was also leaking. So I pulled both seals.

The issue was pretty self explanatory once the seals were out of the way.

I proceeded to pull the top end and found yet more goodness .

.

There was some transfer and some shallow scratches, my buddy and I cleaned it up and the cylinder looks pretty decent now. Figured I'd try and save myself $200 by running this cylinder..

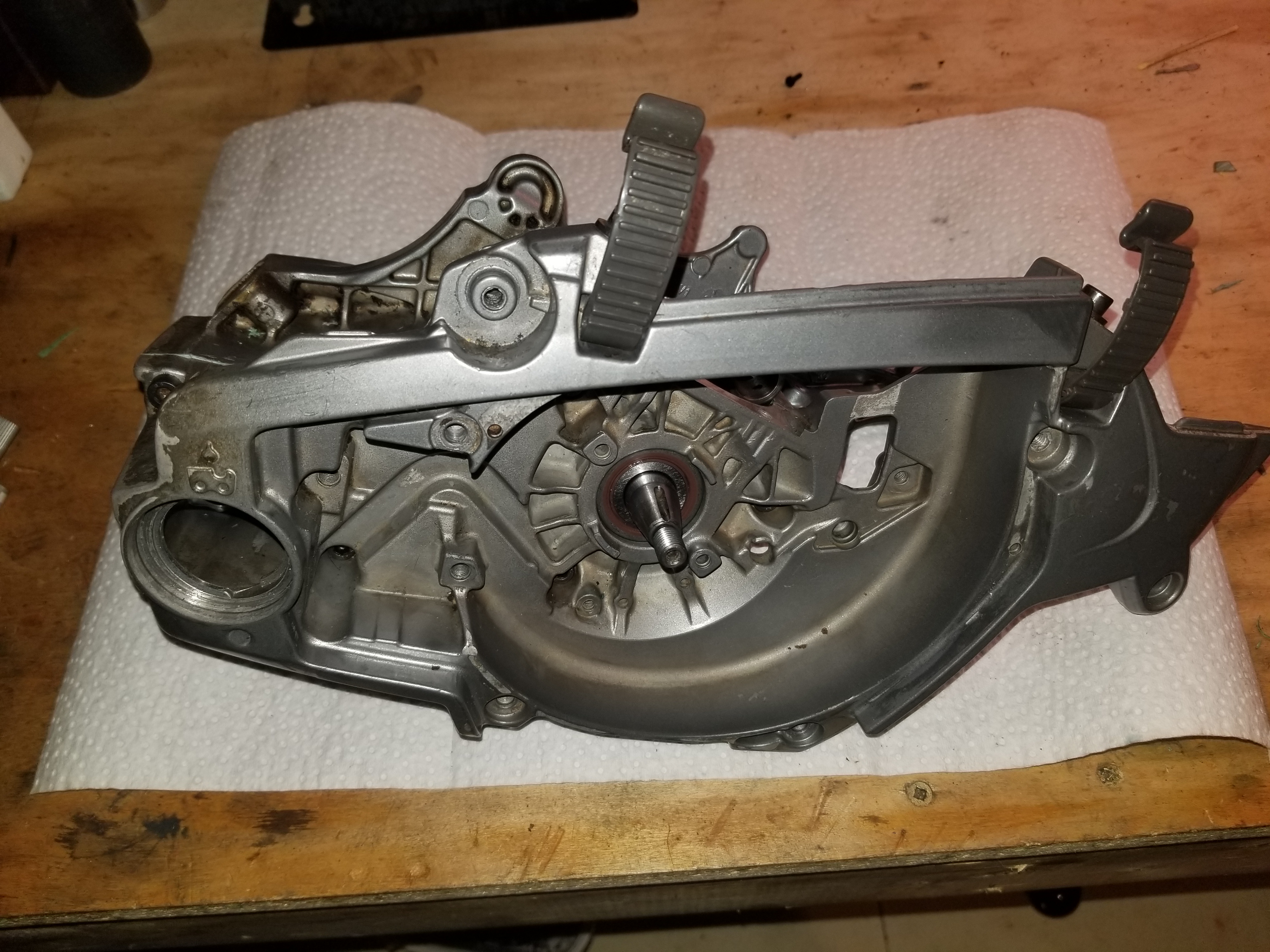

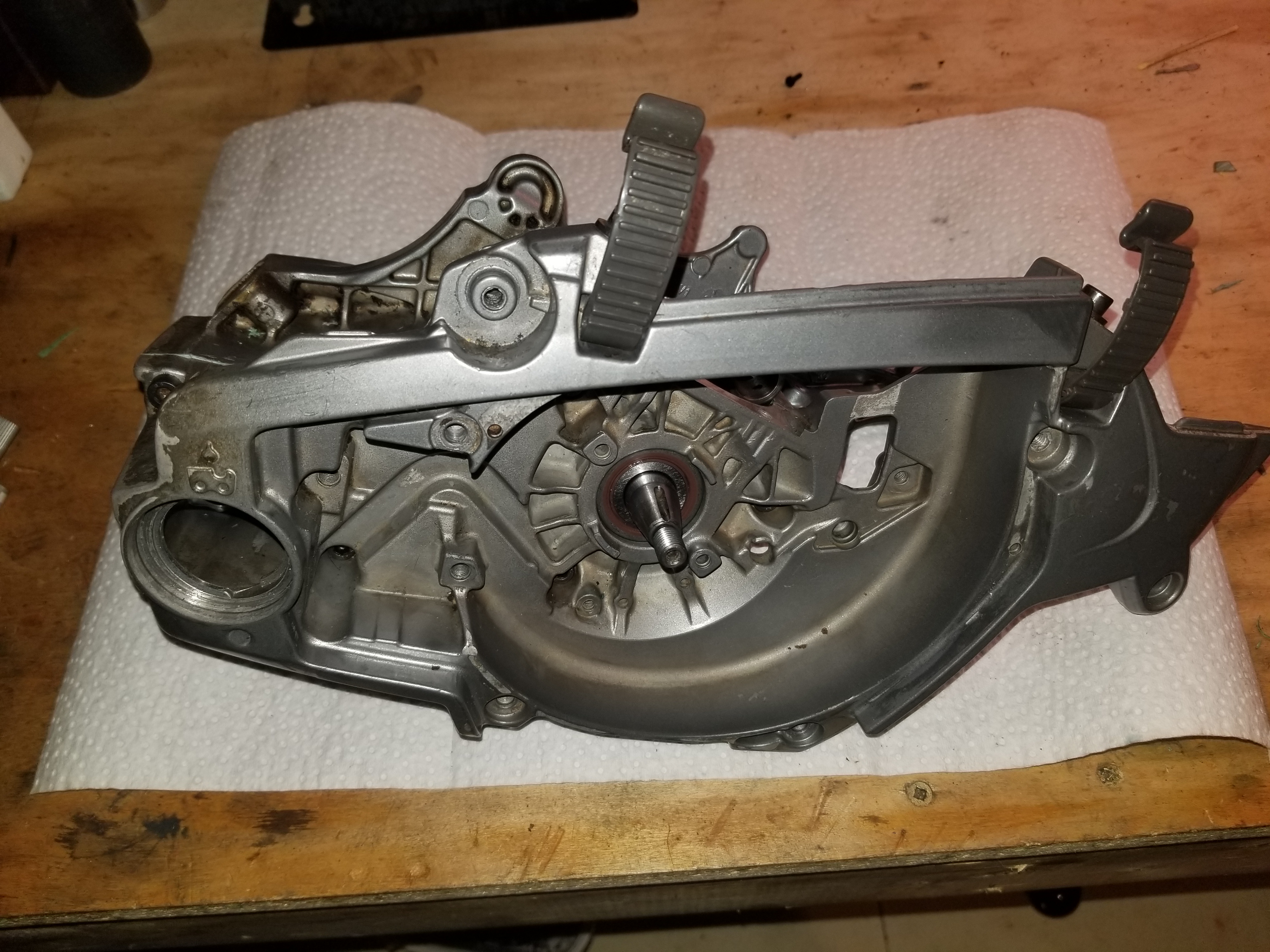

Made a case splitter from some steel I had laying around. It worked perfect and cost me nothing but and hour of time. Win!!

Theres all the trash that got sucked through the transfers.

Ordered OEM bearings, seals and gaskets and went to work building the bottom end. A meteor piston with caber ring was chosen to complete the top end.

Decided to do a muffler mod to try and let the exhaust escape faster and maybe reduce how hot the muffler gets. I enlarged the inlet hole on the top by about 100%. I then put a second hole on the outlet which will increase flow but still allow me to use this saw in a provincial forest.

Also trimmed the top cover to let more air out like the new model 562s .

Heres the complete saw. I have a lathe and was going to do a no base gasket build but once I measured the squish with the base gasket at give or take .030" I called it good enough. The first pull of the cord made me happy that I didnt do a no base gasket and pop up build as this saw has good compression that's for sure.

Initial start up was quick, I purged it like 5 times, pulled it over twice and it fired . Toom off the choke and on the 3rd pull it fired right up. I let it run on high idle for a bit and then pulled the trigger. It stalled instantly and then I couldn't get it to restart.. I was like "maybe this is and auto tune issue?"

Let it sit for a min and tried again and it fired right back up, I left it on high idle for a min just to get the engine temp up. Once it got warm i pulled the trigger and it settled down into a nice idle, throttle response was a bit lazy at first but it soon got crisp and very responsive..

I put the saw to some 18" dry frozen poplar and it cut with authority and got better with each cookie.

I must say I've only run this saw for about 10 mins but already I'm super impressed with it. It has the power of my pre xtorq 365 special without the vibration. It's also lighter and seems more nimble to me.

I think is my new favorite saw, been staring at it on my bench since last fall, so glad its done.

It was well worth the wait and I think I got maybe $275 in it so I'm very happy.

Joining this forum and watching Walt's videos on youtube have sure been a blessing. Cutting wood is no longer a chore and really it's not expensive to build your own saws vs buying a new one.

Thabks to all that have helped me out along the way..

Heres the saw when I started, filthy but complete.

After some cleaning I came to find out it was a 2014 model with an EL-48 carb and a 6 screw case..

The saw failed both vac and pressure tests so I started tearing it down.

Pulled the flywheel and found this.

Bottom of the seal was completely gone.

Other side was also leaking. So I pulled both seals.

The issue was pretty self explanatory once the seals were out of the way.

I proceeded to pull the top end and found yet more goodness

There was some transfer and some shallow scratches, my buddy and I cleaned it up and the cylinder looks pretty decent now. Figured I'd try and save myself $200 by running this cylinder..

Made a case splitter from some steel I had laying around. It worked perfect and cost me nothing but and hour of time. Win!!

Theres all the trash that got sucked through the transfers.

Ordered OEM bearings, seals and gaskets and went to work building the bottom end. A meteor piston with caber ring was chosen to complete the top end.

Decided to do a muffler mod to try and let the exhaust escape faster and maybe reduce how hot the muffler gets. I enlarged the inlet hole on the top by about 100%. I then put a second hole on the outlet which will increase flow but still allow me to use this saw in a provincial forest.

Also trimmed the top cover to let more air out like the new model 562s .

Heres the complete saw. I have a lathe and was going to do a no base gasket build but once I measured the squish with the base gasket at give or take .030" I called it good enough. The first pull of the cord made me happy that I didnt do a no base gasket and pop up build as this saw has good compression that's for sure.

Initial start up was quick, I purged it like 5 times, pulled it over twice and it fired . Toom off the choke and on the 3rd pull it fired right up. I let it run on high idle for a bit and then pulled the trigger. It stalled instantly and then I couldn't get it to restart.. I was like "maybe this is and auto tune issue?"

Let it sit for a min and tried again and it fired right back up, I left it on high idle for a min just to get the engine temp up. Once it got warm i pulled the trigger and it settled down into a nice idle, throttle response was a bit lazy at first but it soon got crisp and very responsive..

I put the saw to some 18" dry frozen poplar and it cut with authority and got better with each cookie.

I must say I've only run this saw for about 10 mins but already I'm super impressed with it. It has the power of my pre xtorq 365 special without the vibration. It's also lighter and seems more nimble to me.

I think is my new favorite saw, been staring at it on my bench since last fall, so glad its done.

It was well worth the wait and I think I got maybe $275 in it so I'm very happy.

Joining this forum and watching Walt's videos on youtube have sure been a blessing. Cutting wood is no longer a chore and really it's not expensive to build your own saws vs buying a new one.

Thabks to all that have helped me out along the way..