I am glad I was working on a project saw. Took it apart, cleaned it up, and decided to try the big bore kit. Install went well, used the good clips. Went to start it, and I knew something wasn't right. After much fuss, I actually got it to run for little spurts. Peeped into the exhaust port and looked at the nice deep gouges. Oh :censored: .

Fine and dandy! It is only a disaster! Swap the stock jug and piston back on! I had to press the piston out with a screwdriver down the spark plut hole, and then force the jug off with pry bars against the case!!!

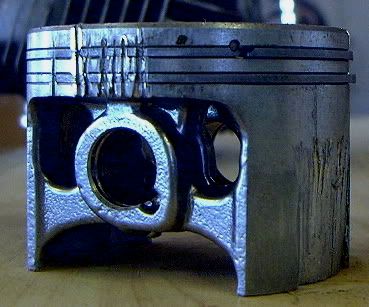

What was then before my eyes was amazing. I will post pix tomorrow. Camera is charging up. Clips did not come off. Instead the piston and cylinder got real cozy. After reading 1953greg's thread down there I realized where things went wrong. The edges of the ports are squared off. I needed to get in there and round them all off. Just a little late now.

So after I washed out all the shrapnel from the crank, and cleaned everything up again I re-installed the stock 046 stuff. Fired right up.

So now I have a real nice gouged piston with a broken skirt for a decoration, and a gouged out cylinder for a paper weight.

-Pat

Fine and dandy! It is only a disaster! Swap the stock jug and piston back on! I had to press the piston out with a screwdriver down the spark plut hole, and then force the jug off with pry bars against the case!!!

What was then before my eyes was amazing. I will post pix tomorrow. Camera is charging up. Clips did not come off. Instead the piston and cylinder got real cozy. After reading 1953greg's thread down there I realized where things went wrong. The edges of the ports are squared off. I needed to get in there and round them all off. Just a little late now.

So after I washed out all the shrapnel from the crank, and cleaned everything up again I re-installed the stock 046 stuff. Fired right up.

So now I have a real nice gouged piston with a broken skirt for a decoration, and a gouged out cylinder for a paper weight.

-Pat

(cool smiley)

(cool smiley)