Hello all!

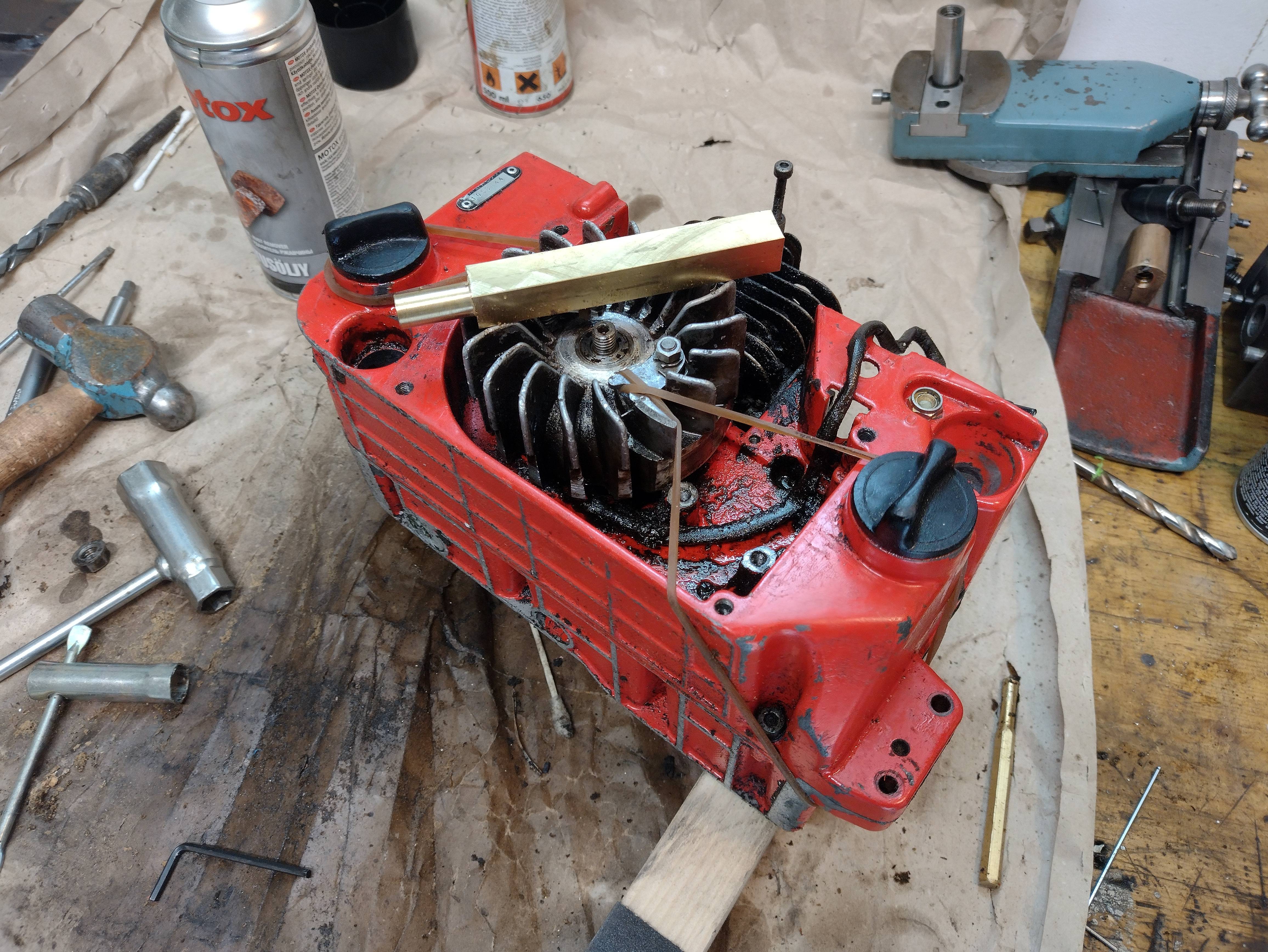

I just bought an old chainsaw, Jonsered 451 EV (supposed to be in running order but I will have to see) and I plan to renovate it and actually use it too. I just like older tech that can be more readily serviced at home than buying new stuff, and all the plastic on modern saws too. I like Jonsereds, my granddad had those and I remember using a small one as a kid to help with the firewood, remember I was bloody scared of it!

But there are already some questions I have, mainly it's refinishing related. The covers on this saw are all aluminum and I was planning to repaint them, but what kind of paint do you guys recommend for this? 2K or 1K? A mix of paint and clear coat? I have used 2k epoxy before when I worked on a milling machine, but epoxy ages badly and is not shock tolerant so I don't think it's viable here except as a primer coat. 1K paint would be simple to get but not that durable, what did Jonsered use from factory I wonder?

Since most of this saw is aluminum, I don't think it's safe to use paint strippers, at least not the ones I use (lye!), are there even aluminum safe paint strippers?

Probably have more questions later but gotta go get the kids ready for school.

I just bought an old chainsaw, Jonsered 451 EV (supposed to be in running order but I will have to see) and I plan to renovate it and actually use it too. I just like older tech that can be more readily serviced at home than buying new stuff, and all the plastic on modern saws too. I like Jonsereds, my granddad had those and I remember using a small one as a kid to help with the firewood, remember I was bloody scared of it!

But there are already some questions I have, mainly it's refinishing related. The covers on this saw are all aluminum and I was planning to repaint them, but what kind of paint do you guys recommend for this? 2K or 1K? A mix of paint and clear coat? I have used 2k epoxy before when I worked on a milling machine, but epoxy ages badly and is not shock tolerant so I don't think it's viable here except as a primer coat. 1K paint would be simple to get but not that durable, what did Jonsered use from factory I wonder?

Since most of this saw is aluminum, I don't think it's safe to use paint strippers, at least not the ones I use (lye!), are there even aluminum safe paint strippers?

Probably have more questions later but gotta go get the kids ready for school.