You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Diesel Super Split

- Thread starter Whitbread

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Now you're just showing off.

Whitbread

ArboristSite Operative

Next time I run it I'll get a video guys, I promise!

Come on up for a race sandhill! The lake is frozen over and ready for some Ricky Bobby action !

!

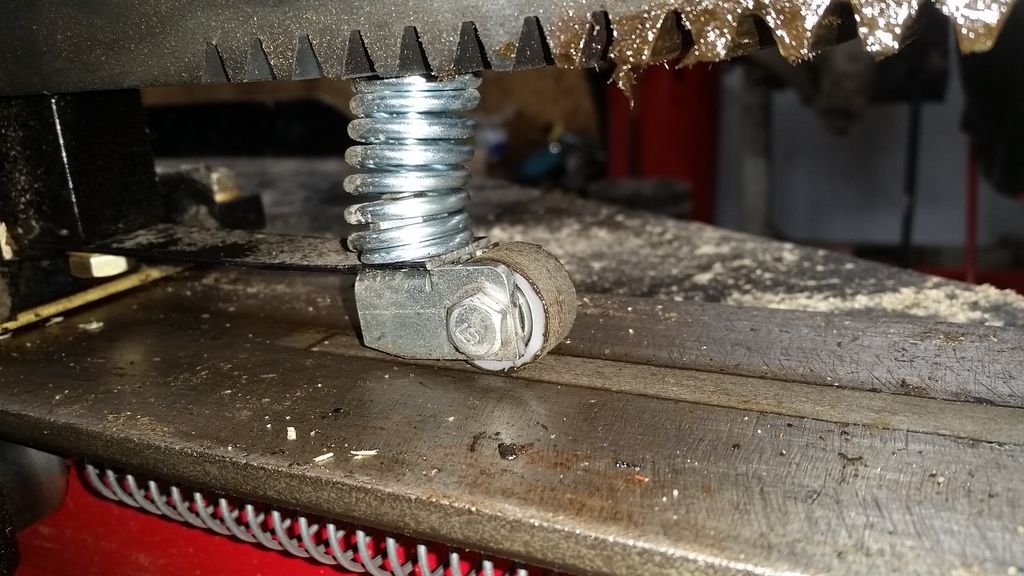

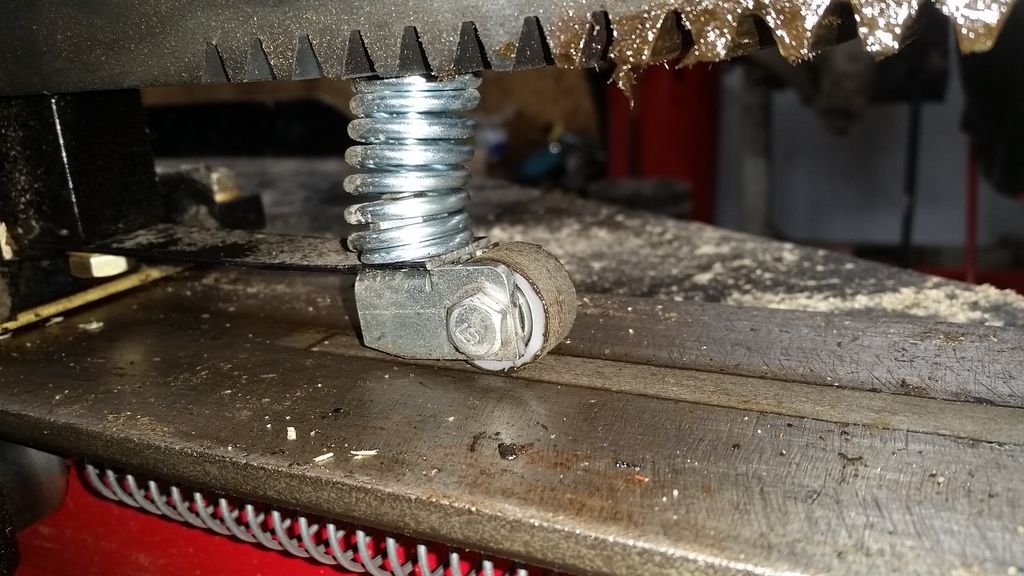

On the load I split the other day I noticed the ram being sluggish to return and despite liberal wd40 use, the little follower bearing froze up after about 8 cords of use. I grabbed a piece of UHMW round and two 1/4"x5/8" double sealed ball bearings and made a new roller. Hopefully this one lasts a little longer.

Come on up for a race sandhill! The lake is frozen over and ready for some Ricky Bobby action

!

!On the load I split the other day I noticed the ram being sluggish to return and despite liberal wd40 use, the little follower bearing froze up after about 8 cords of use. I grabbed a piece of UHMW round and two 1/4"x5/8" double sealed ball bearings and made a new roller. Hopefully this one lasts a little longer.

Ill be interested to see how the UHMWPE holds up. There is a fair bit of force on that bearing.

Whitbread

ArboristSite Operative

Turns out that UHMW will deform if it sits outside in zero degree weather for a month un-used. However, being that it slides so well against steel, it really didn't matter a whole lot. Once the bearings in the bottom of the carriage warmed up a touch, it returned on it's own and let me finish the pile easily.Ill be interested to see how the UHMWPE holds up. There is a fair bit of force on that bearing.

I pulled it in the shop and I'll make an aluminum roller with the same 2 sealed ball bearings inside and see how that fares for tomorrows splitting.

Here's the video y'all have been dying for

mijdirtyjeep

ArboristSite Operative

I pulled it in the shop and I'll make an aluminum roller with the same 2 sealed ball bearings inside and see how that fares for tomorrows splitting.

Love the sound of that Diesel purring!!

I am a diesel head as well, Duramax for me, wife has a GC EcoDiesel, and we just turned out TDI back into VW.

Now you have me wanting to put on on my SuperSplit.

On mine, it would eat that cam follower bearing up about every 5-6cords. Heck, I have a nice grove in the top of the beam form that bearing frozen up and not rolling. I ended up just bring the old cam follower bearing into the local bearing shop and he match the O.D with roller bearing like you have. It takes two like yours to make the same width as the old cam follower bearing it replaced.

So far I have put over 10/cords though it and have not had it freeze up. Last week, one of my return springs broke off and it returned just fine with only one spring! It is something SS ought to start selling as a replacement part. Bonus is, you can by 6 (only need two at a time) for the same price as one cam follower!

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$56.99 ($0.38 / Foot)

$69.99 ($0.47 / Foot)

Arborist Rigging Rope Bull Rope Black (1/2 in x 150ft) Polyester Braided Arborist Rope 48 Strands for Tree Work Camping or Swinging…

UIERTIO

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$38.99 ($0.39 / Foot)

$40.99 ($0.41 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

ChoppyChoppy

Tree Freak

I shall power one by an open headered 454. That'll make panties drop!

Whitbread

ArboristSite Operative

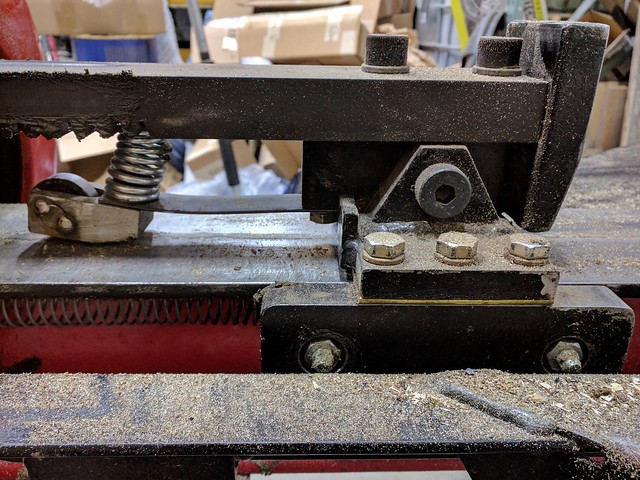

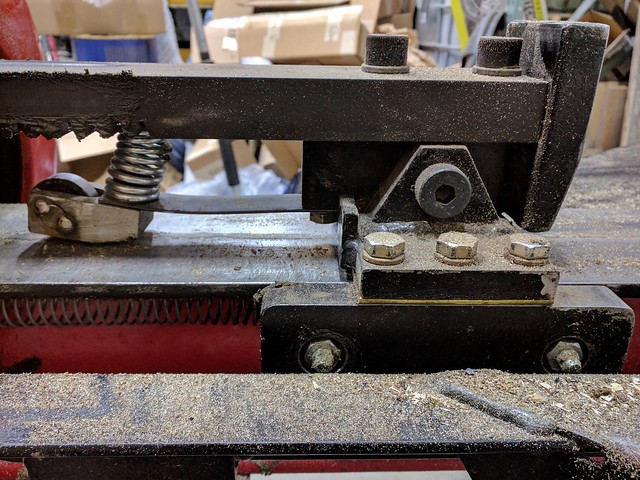

After fighting stiff return issues pretty much since the second wood splitting session, I think I finally figured out a follower bearing solution that will last. I milled a new block out and used a 12mm IDx24mm OD double sealed ball bearing. I also made the bolts for the underside rollers greaseable.

I also finally had to put fuel in it this year. The tank is 1.8 gallons and lasted at least 14 full cords, lost exact count.

2017-09-29_09-57-24 by Matt Whitbread, on Flickr

2017-09-29_09-57-24 by Matt Whitbread, on Flickr

I also finally had to put fuel in it this year. The tank is 1.8 gallons and lasted at least 14 full cords, lost exact count.

2017-09-29_09-57-24 by Matt Whitbread, on Flickr

2017-09-29_09-57-24 by Matt Whitbread, on FlickrKiwiBro

Mill 'em, nails be damned.

Has anyone tried using an engineering plastic instead of the stock bearings on their SS? Replace the bearings under the carriage (and the brass wear plate for that matter) with UHMWPE for example. Also, the lift spring bearing. I think the idea has merit but I'm still on the original bearings - they get a good soak between seasons and checked before each session.

Casey sent me two very narrow sealed bearings that I installed this summer. Have not had any maintenance or issues with return, and it has been rained on a couple times to boot when I didn't expect it to. Now it is covered nightly or brought in, depending. Using it daily. The bearings are superb and should be a stock item.

I too had good luck with original bearing with some maintenance.

Tried some engineered plastic rod that I drilled. Didn't work for me. Drilled oh so slight off center and trouble spinning with debris on beam.

Whitbread: Interesting looking wood rack uprights in your recent photo. Nice set-up!

I too had good luck with original bearing with some maintenance.

Tried some engineered plastic rod that I drilled. Didn't work for me. Drilled oh so slight off center and trouble spinning with debris on beam.

Whitbread: Interesting looking wood rack uprights in your recent photo. Nice set-up!

ChoppyChoppy

Tree Freak

Whitbread

ArboristSite Operative

Yeah, I tried a oil impregnated uhmw roller and it deformed over time. It still slid ok even not rolling, but not amazing.Has anyone tried using an engineering plastic instead of the stock bearings on their SS?

I tried a pair of small bearings I had laying around, but they kept not wanting to roll over the tiniest bits of junk on the beam. The new large bearing seems to roll over anything without issue.Casey sent me two very narrow sealed bearings that I installed this summer. Have not had any maintenance or issues with return, and it has been rained on a couple times to boot when I didn't expect it to. Now it is covered nightly or brought in, depending. Using it daily. The bearings are superb and should be a stock item.

I too had good luck with original bearing with some maintenance.

Tried some engineered plastic rod that I drilled. Didn't work for me. Drilled oh so slight off center and trouble spinning with debris on beam.

Whitbread: Interesting looking wood rack uprights in your recent photo. Nice set-up!

They are cheap, quick, and easy racks. I found a photo on the net that gave me the idea and I just lengthened them. The intention was to build a permanent woodshed in the same spot, but things just didn't happen this year as intended. I figure I'll burn everything that's stacked here and build my my permanent shed in the spring.

No, I slowed it down. 300rpm on flywheels is max recommended by SS, I'm running about 230-240rpm. Engagement is much gentler and it still takes 3 people to keep up with. It works out to 2100-2200 engine rpm which is the 12lb/ft torque peak of the lister. I'll snap a better video today now that I have someone to hold the phone.Is the one in the video at full rpm? For some reason I thought they were faster. It's pretty much on parts speed wise with my processor, about 4-5 second cycle.

KiwiBro

Mill 'em, nails be damned.

Thanks. I should have been clearer. Didn't mean the plastic as a roller, rather just a sliding block. /but it seems you tried that and still found the larger diameter roller to be the go. That's great to know, thanks. Are you guys finding much wear in the underside of the top flange from the tracking of the carriage bearings? I've got a fair lip under there.Yeah, I tried a oil impregnated uhmw roller and it deformed over time. It still slid ok even not rolling, but not amazing.

I tried a pair of small bearings I had laying around, but they kept not wanting to roll over the tiniest bits of junk on the beam. The new large bearing seems to roll over anything without issue.

They are cheap, quick, and easy racks. I found a photo on the net that gave me the idea and I just lengthened them. The intention was to build a permanent woodshed in the same spot, but things just didn't happen this year as intended. I figure I'll burn everything that's stacked here and build my my permanent shed in the spring.

No, I slowed it down. 300rpm on flywheels is max recommended by SS, I'm running about 230-240rpm. Engagement is much gentler and it still takes 3 people to keep up with. It works out to 2100-2200 engine rpm which is the 12lb/ft torque peak of the lister. I'll snap a better video today now that I have someone to hold the phone.

Whitbread

ArboristSite Operative

One design aspect of the SS that has drove me (and my wrist) nuts is the non ergonomic upward yank of the engagement handle. So I finally did something about it! Used bits of the original lever pivot bracket to make a bell crank so you pull the lever toward the wedge to engage. Such a more natural and easier effort, only takes 1 finger of force to engage now. An upside down bolt welded to the side of the bell crank hits the original super split bell crank to disengage the rack in the event you need to stop it mid travel. Two short collars are welded to the frame that a bolt runs through for the pivot of the new bell crank.

Nice more pictures please. I have the same wrist and shoulder problems. I tried to figure this out but gave up. Thank you!

Sent from my SM-N950U using Tapatalk

Sent from my SM-N950U using Tapatalk

Dont think I had seen this thread before. Impressive mods to your SS. Have to get my welder out again.....

Whitbread

ArboristSite Operative

I can definitely snap some more pics for you. Heck, it would be really easy to offer a kit that clamps on instead of welding. If there are enough requests, I could certainly make something up.Nice more pictures please. I have the same wrist and shoulder problems. I tried to figure this out but gave up. Thank you!

Thank you sir! The thing works like a champ! The small table size was driving me nuts today working on 28" oak rounds though.Dont think I had seen this thread before. Impressive mods to your SS. Have to get my welder out again.....

Waltzie

ArboristSite Member

I’d buy one of those kits to switch the handle

Similar threads

- Replies

- 1

- Views

- 669

- Replies

- 1

- Views

- 241

- Replies

- 3

- Views

- 655

- Replies

- 13

- Views

- 1K

- Replies

- 5

- Views

- 2K