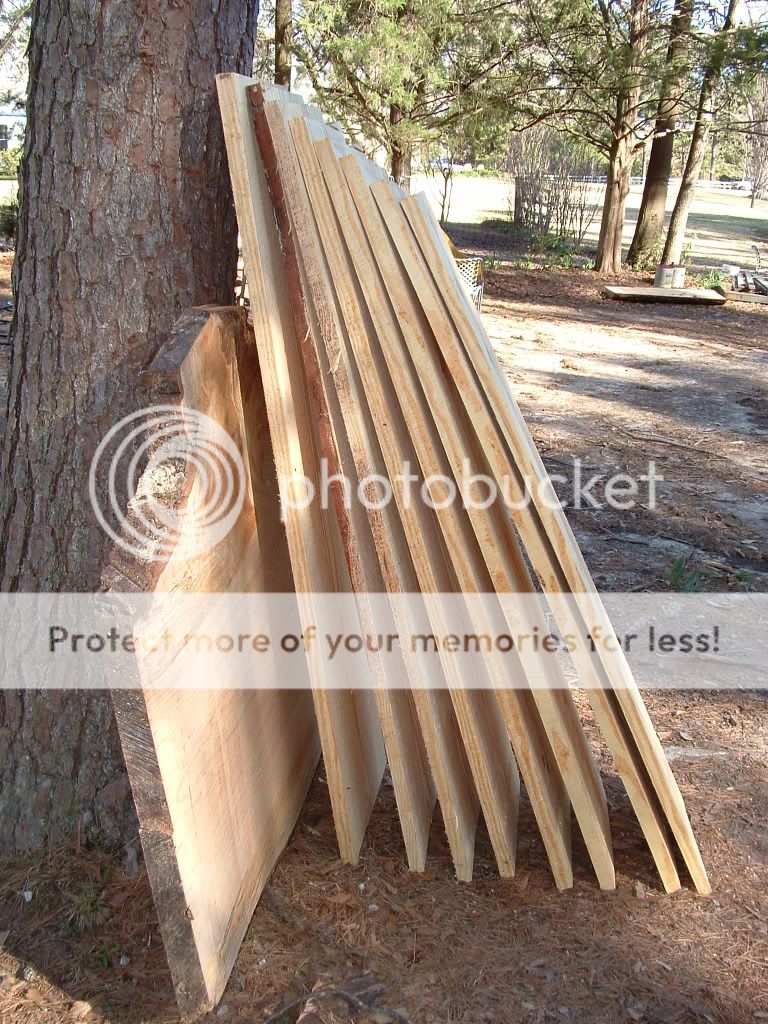

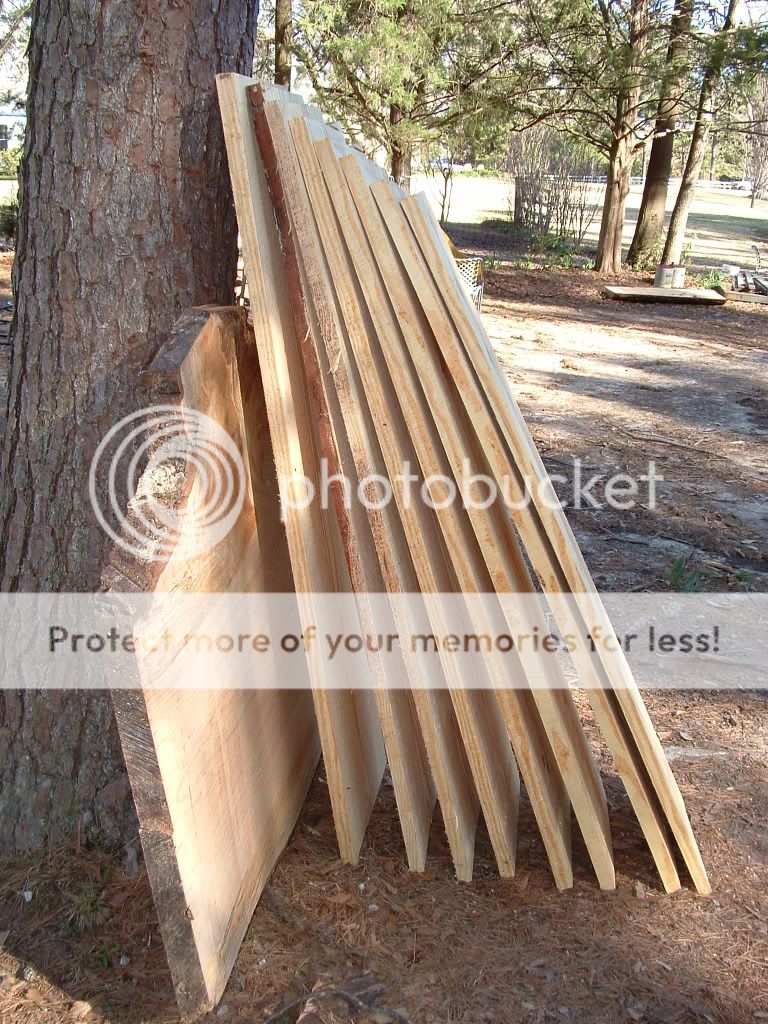

Nice boards! What's the piece they're leaning up on though? That looks promising.

So are you having a hard time re-starting the saw if you shut it off hot? There are a few basic things to check.

If you're not also having trouble with it wanting to stall out when it's hot, then the first thing to check is the spark plug. A plug running outside its heat range will still produce a good spark at high RPM but won't fire at the RPMs produced when pulling the recoil if it's still too hot. I've chased my tail a few times with this problem. I'm unsure if a worn-out plug could develop this symptom; the times I've encountered it, it was the wrong plug altogether. Also make sure you don't have a "blue" plug with an internal resistor - these can cause major issues and can apparently even damage ignitions.

Other possibilities with hot-start issues are either a bad ignition coil, or a malfunctioning fuel tank vent. Both of those usually cause issues with the saw while it's running as well though; either wanting to stall or not idle, or significant power/RPM loss. The tank vent is easy to check though - if you're having trouble, crack the cap and see if it helps. Ignition is a bit trickier to check; if you've ruled out the spark plug, you can check for spark the old-fashioned way. But if you have a good digital voltmeter, you can pull the plug and put the meter between the ignition wire and the saw. With a solid pull you should get at least 10,000 Volts , though 15-20KV is better for a good modern coil.