steven1955

ArboristSite Member

Hi folks,

After a 3 month hiatus I'm back to working on my neighbors Husky 55 Rancher. He actually gave the saw to me, but I'll offer it back to him for the cost of parts if and when it's running again.

I previously sought your help in this thread.

Model: Husqvarna 55 Rancher

Code on tag top line: 967 05 29.00

Code on tag bottom line: 02 2301618

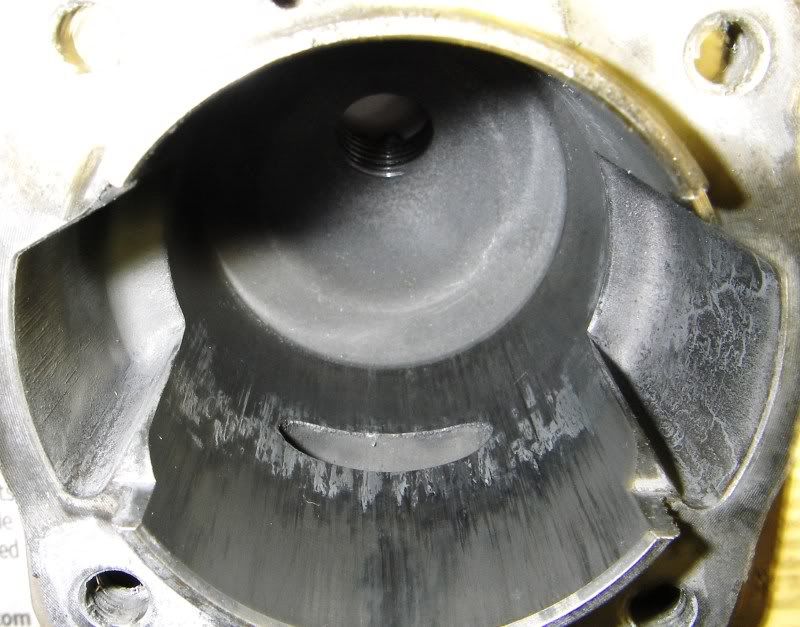

Back in September I was totally newbish and totally missed the scored piston. I looked and thought the scoring was carbon deposits and unburned oil. I should have known better and learned from your experience.

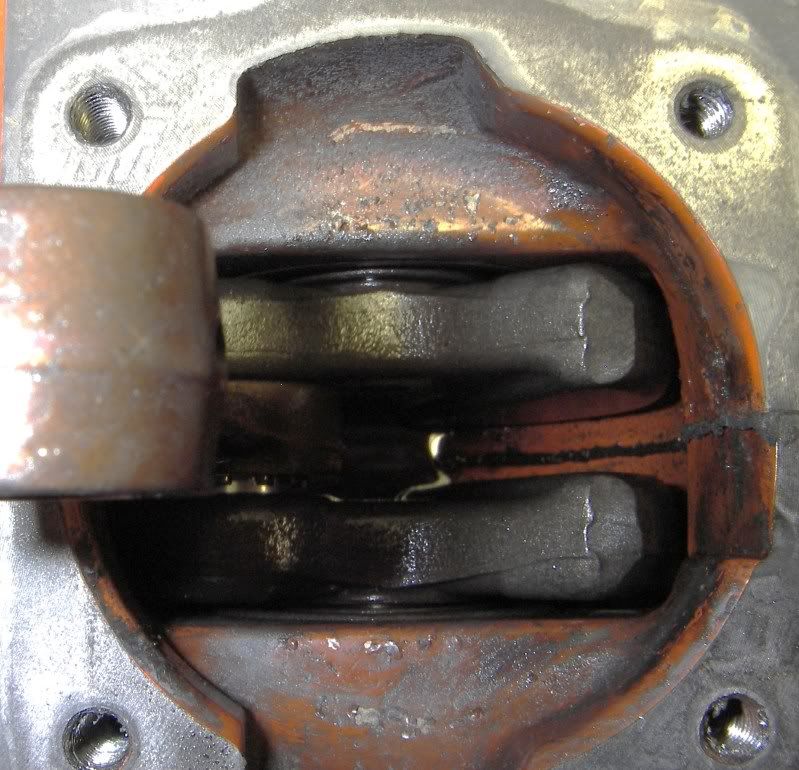

Today I vacuum and pressure tested the Husky supplying vacuum and pressure through the spark plug hole. I installed a piece of rubber from an inner tube between the muffler and cylinder and between the carb and carb mount This left the white foamy rubbery impulse coupling, the black rubber induction pipe, and the white plastic "cover" that the carb mounts to in the system that was tested. I did this because I wanted to test more than the crank seals and base gasket for leaks, and I didn't want to fabricate a fixture to block off the intake port and impulse coupling port.

Vacuum test results: I pulled 13 inHg (inches of mercury) and that vacuum held with no leakage for 30 minutes. Rotating the crank had no effect.

Pressure test:

a. 6 to 7 psi (a lot) you could hear a leak in the area of the induction pipe.

b. 5 psi held using a pressure regulator. I then bubble tested the crank seals and base gasket. No leaks. Couldn't get to the impulse coupling or induction pipe due to the white plastic cover/carb mount.

c. 5 psi no audible leaks, but pressure did drop to 3.5 psi in about two minutes.

d. 3.5 psi dropped to 1.5 psi in about 30 minutes.

e. Rotating the crank had no effect.

My suspicion is that the slow leak under pressure is either the impulse coupling, which was new three months ago, or the induction pipe, which is original. On the same hand I suspect that all Ranchers will leak some under pressure because there is no clamp on the induction pipe. It seals solely due to it's rubbery stretchyness.

I am now convinced that the piston was scored due to lack of lubrication due to bad gas. My neighbor used to buy low test 10% ethanol gas and stored it in an unsealed gas can. I don't know what was used for premix oil. (He now buys Stihl High Performance 2-Cycle Engine Oil in the orange bottle, uses high test gas, and seals his gas cans.)

It's also possible that the saw could have been running lean due to carb issues or a leaky fuel line. The carb was rebuilt in September and the fuel line and filter were replaced when I missed the scored piston. Tank vent was venting.

Question 1: Anyone have a different or better diagnosis? (I'm willing to do other checks.)

Question 2: Is the leakage rate under pressure (3.5 psi dropping to 1.5 psi in about 30 minutes) anything to be concerned about?

After a 3 month hiatus I'm back to working on my neighbors Husky 55 Rancher. He actually gave the saw to me, but I'll offer it back to him for the cost of parts if and when it's running again.

I previously sought your help in this thread.

Model: Husqvarna 55 Rancher

Code on tag top line: 967 05 29.00

Code on tag bottom line: 02 2301618

Back in September I was totally newbish and totally missed the scored piston. I looked and thought the scoring was carbon deposits and unburned oil. I should have known better and learned from your experience.

Today I vacuum and pressure tested the Husky supplying vacuum and pressure through the spark plug hole. I installed a piece of rubber from an inner tube between the muffler and cylinder and between the carb and carb mount This left the white foamy rubbery impulse coupling, the black rubber induction pipe, and the white plastic "cover" that the carb mounts to in the system that was tested. I did this because I wanted to test more than the crank seals and base gasket for leaks, and I didn't want to fabricate a fixture to block off the intake port and impulse coupling port.

Vacuum test results: I pulled 13 inHg (inches of mercury) and that vacuum held with no leakage for 30 minutes. Rotating the crank had no effect.

Pressure test:

a. 6 to 7 psi (a lot) you could hear a leak in the area of the induction pipe.

b. 5 psi held using a pressure regulator. I then bubble tested the crank seals and base gasket. No leaks. Couldn't get to the impulse coupling or induction pipe due to the white plastic cover/carb mount.

c. 5 psi no audible leaks, but pressure did drop to 3.5 psi in about two minutes.

d. 3.5 psi dropped to 1.5 psi in about 30 minutes.

e. Rotating the crank had no effect.

My suspicion is that the slow leak under pressure is either the impulse coupling, which was new three months ago, or the induction pipe, which is original. On the same hand I suspect that all Ranchers will leak some under pressure because there is no clamp on the induction pipe. It seals solely due to it's rubbery stretchyness.

I am now convinced that the piston was scored due to lack of lubrication due to bad gas. My neighbor used to buy low test 10% ethanol gas and stored it in an unsealed gas can. I don't know what was used for premix oil. (He now buys Stihl High Performance 2-Cycle Engine Oil in the orange bottle, uses high test gas, and seals his gas cans.)

It's also possible that the saw could have been running lean due to carb issues or a leaky fuel line. The carb was rebuilt in September and the fuel line and filter were replaced when I missed the scored piston. Tank vent was venting.

Question 1: Anyone have a different or better diagnosis? (I'm willing to do other checks.)

Question 2: Is the leakage rate under pressure (3.5 psi dropping to 1.5 psi in about 30 minutes) anything to be concerned about?