VinceGU05

PSA vitim.

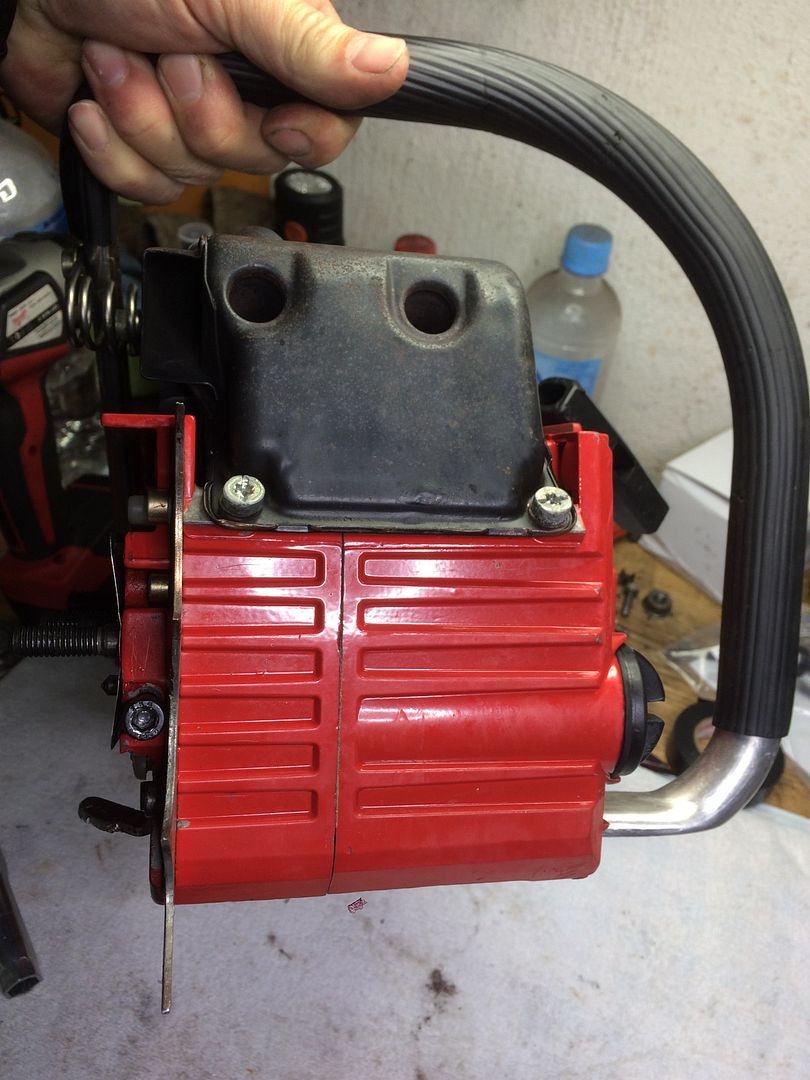

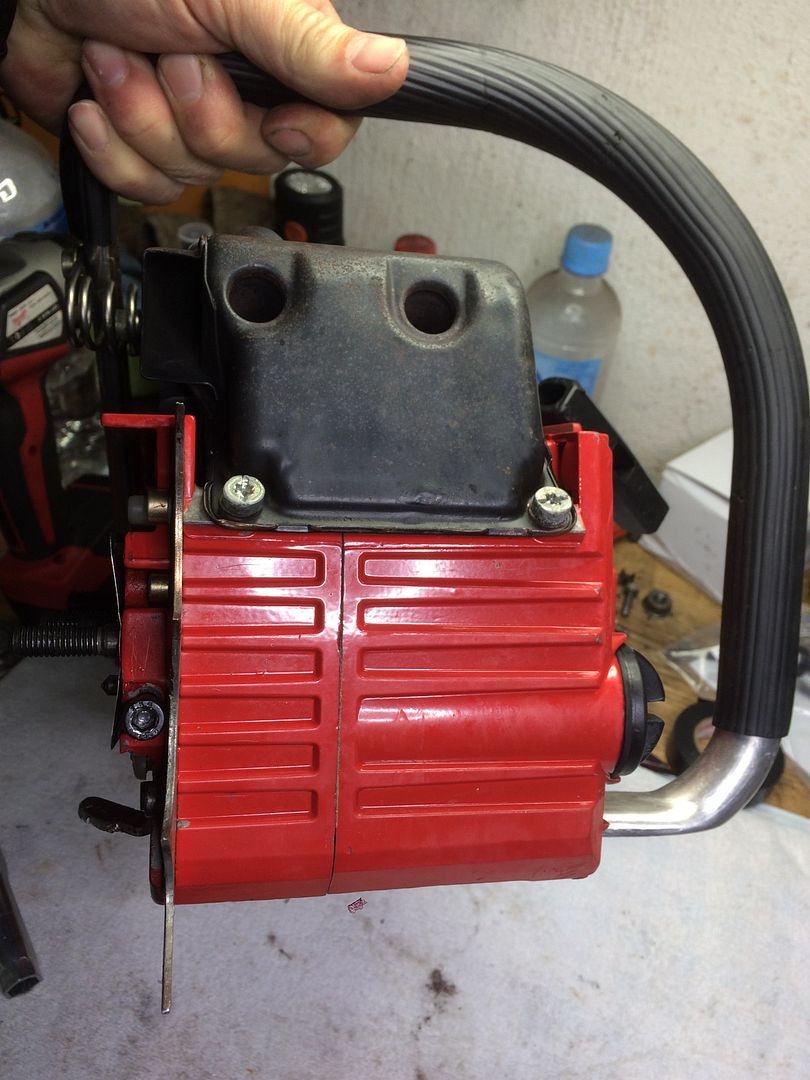

A few people have asked for a bit of a tutorial on louvers. So i have the perfect candidate. This Solo 667SP.

So not every saw is a perfect candidate, so it is a selective thing. Not a great deal was going to help opening up the standard deflector and I might of been able to squeeze a deflector of the right hand side but it may have melted the black plastic cover.

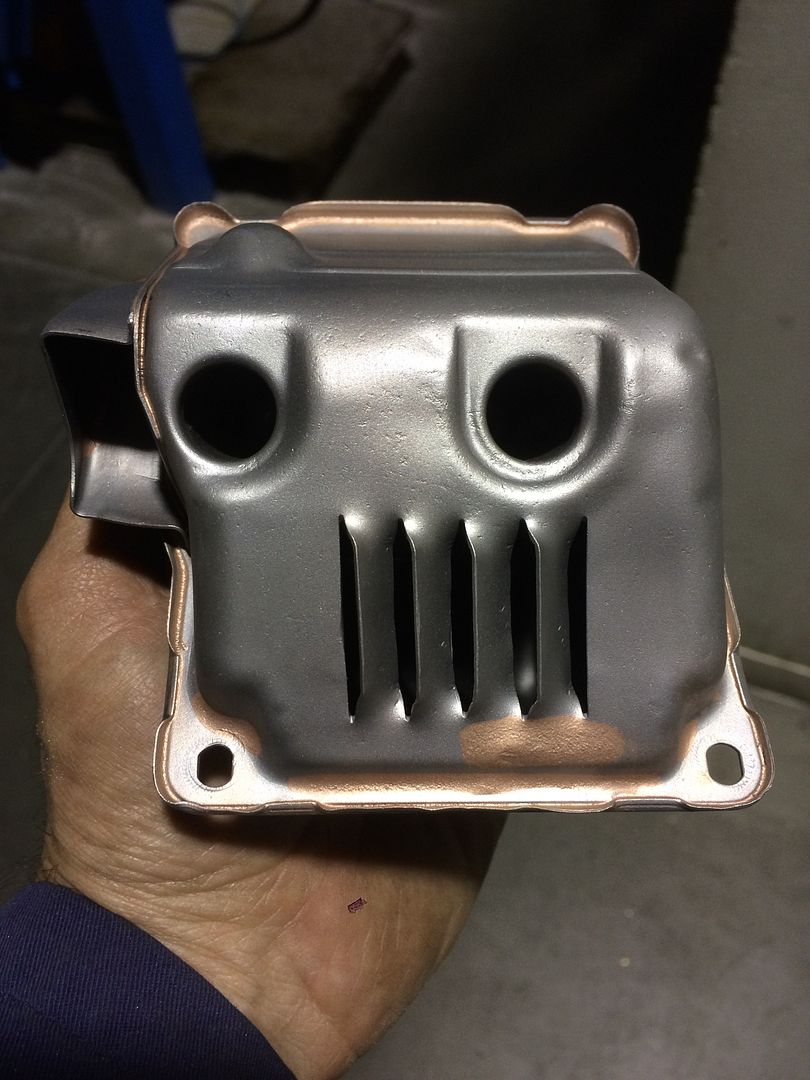

So, once the muffler is off we need to mark out some lines to get a feel of the end product. The height of these ones was 30mm and the pitch was 9mm. between 7 to 9mm is about the right width.

can see that the first set of lines were on an angle. The muffler isn't square, so used the other edge of the muffler to square them up.

using the dremel and slitting wheel the vertical cuts are made.

its very important for the end look that you hold the dremel parallel and square to the lines your cutting.

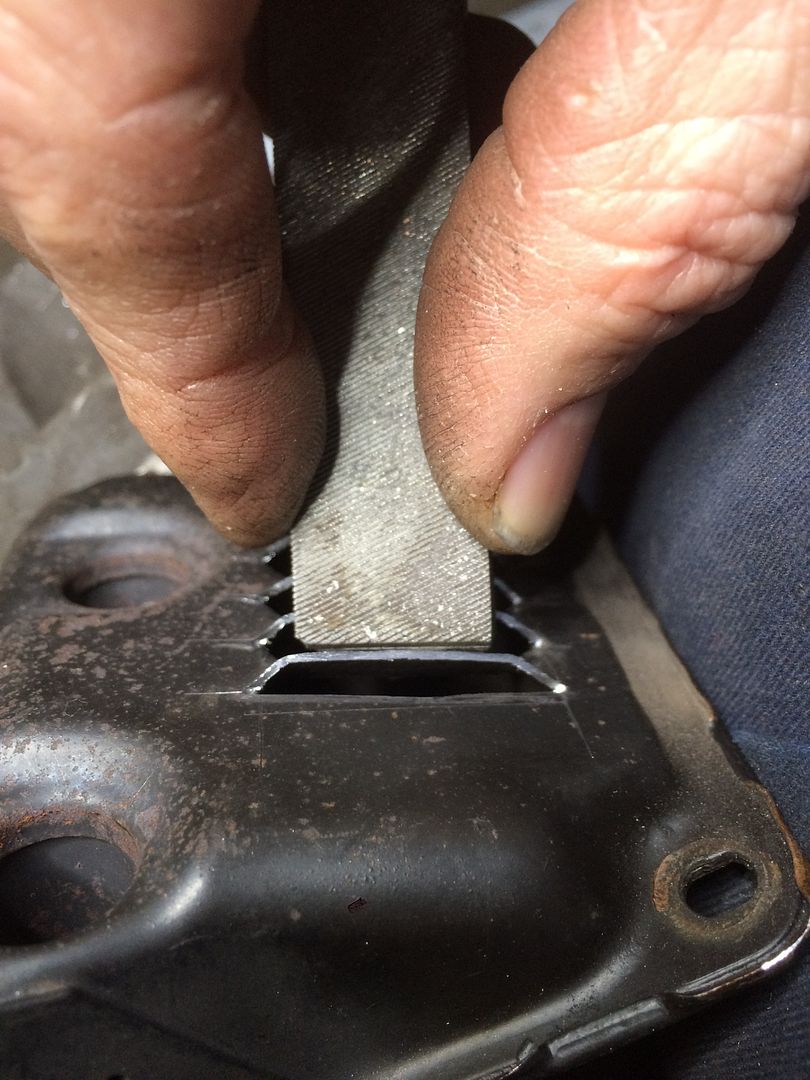

The tools i use are a narrow and wide flat nose pliers; without the serrations as this will mark the louvers and the paint wont hide it. And a thin ruler or something very similar. ( thin small screwdriver)

Either one of these are used to start to lift the first louver so you can get the pliers in.

A bit of care is needed on lifting the first one as its very easy to push down the steel on the left of the first louver to pry it up. once you get the ball rolling its fairly easy.

here is a bit of a clip. not easy holding the phone and bending at the same time but you get the idea.

So not every saw is a perfect candidate, so it is a selective thing. Not a great deal was going to help opening up the standard deflector and I might of been able to squeeze a deflector of the right hand side but it may have melted the black plastic cover.

So, once the muffler is off we need to mark out some lines to get a feel of the end product. The height of these ones was 30mm and the pitch was 9mm. between 7 to 9mm is about the right width.

can see that the first set of lines were on an angle. The muffler isn't square, so used the other edge of the muffler to square them up.

using the dremel and slitting wheel the vertical cuts are made.

its very important for the end look that you hold the dremel parallel and square to the lines your cutting.

The tools i use are a narrow and wide flat nose pliers; without the serrations as this will mark the louvers and the paint wont hide it. And a thin ruler or something very similar. ( thin small screwdriver)

Either one of these are used to start to lift the first louver so you can get the pliers in.

A bit of care is needed on lifting the first one as its very easy to push down the steel on the left of the first louver to pry it up. once you get the ball rolling its fairly easy.

here is a bit of a clip. not easy holding the phone and bending at the same time but you get the idea.