Sty57

Tree Freak

I just read this post last night and it was great.

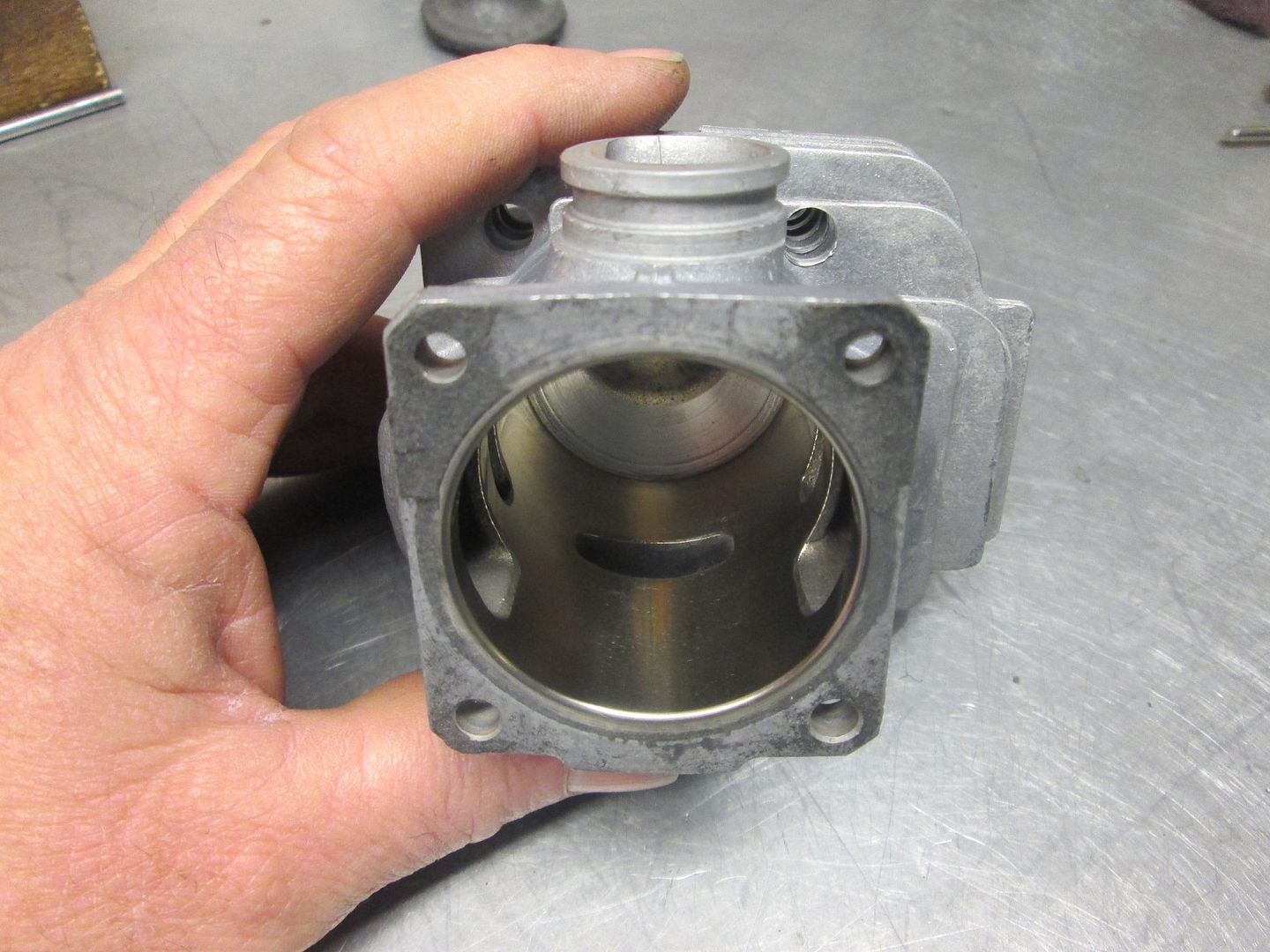

I just wanted to share with some of you that were asking about making the mandrels and how to do it.

I work in a Fab shop that builds excavator buckets and attachments and we make a lot of these for cleaning out the bores after welding and paint. what we use is a "split rollpin" and weld it to the shaft of old stone wheels. We always save the old stones after they are to small to use and take a hammer smash it, clean it up and get a rollpin the size that you need and weld it on. if you don't have a welder and you can find the right size rollpin you could just pound it on and should be good to go.

This is me loading one of the buckets we built this summer.

I just wanted to share with some of you that were asking about making the mandrels and how to do it.

I work in a Fab shop that builds excavator buckets and attachments and we make a lot of these for cleaning out the bores after welding and paint. what we use is a "split rollpin" and weld it to the shaft of old stone wheels. We always save the old stones after they are to small to use and take a hammer smash it, clean it up and get a rollpin the size that you need and weld it on. if you don't have a welder and you can find the right size rollpin you could just pound it on and should be good to go.

This is me loading one of the buckets we built this summer.