Big beam, big ram, multisplit wedge and forget double handleing. I use a boom and winch to load large rounds. I can hookup and drag a load from 2oft by myself, or about 50 ft is someone runs the control cable.

Each situation is different though and we only have to scratch the surface to see that. It was where I was going with all my questions a while back which Sandhill didn't or only very partially answered. What's the absolute best option for one outfit could be utterly useless for another.

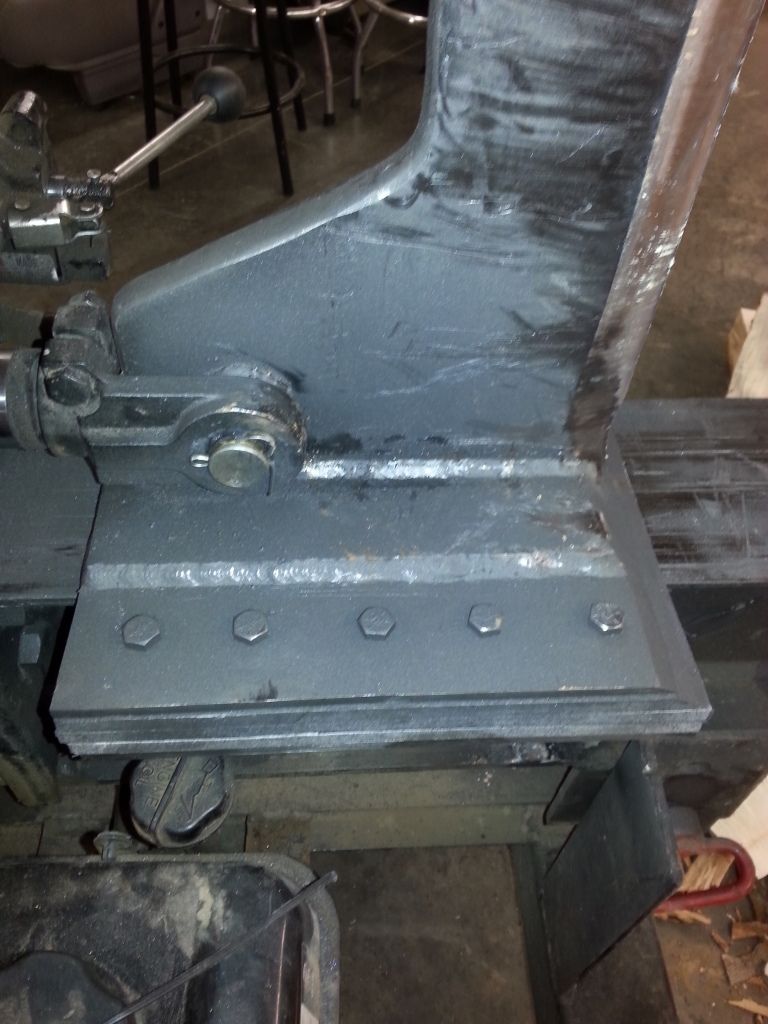

Tongs and winch to bucking station (but what for smaller stuff - stone bucket on tractor FEL, bucket on forks, wheelbarrow, arms and legs, hurl it, etc and into the same big splitter or a different one), buck (big enough saw and bar to not have to come at it from the other side, but how to handle the smaller stuff or oddball tree-service crazies, etc, without it bouncing around), roll into splitter chamber (are we splitting one ring or is the ram long as well as wide and can the chamber handle lots of small stuff too without spewing projectiles all over the place when the load comes on), push through a massive box wedge that splits to exact finished sizes in one go, and into what - a conveyor or straight into a bark/scrag separating chamber (the downside to big, handle-the-wood-once wedges is getting smothered in trash/scrag/bark if not clearing it out regularly), and then into what? Piles, bags, crates, piles and then handled again to stack, stacked (one employee to stack and such like or is the splitter not going to be fed and run while manually stacking the firewood), straight into delivery truck, or what? Splitting green or seasoned? Selling as mixed or specific species (separating out and doing runs of that or just however it comes in, or)?

Point being, GIGO (garbage in, garbage out) when it comes to such decision making processes. The less we know of the specific situation, the less chance the optimal outcome can be reached.

Notwithstanding the interesting ideas, this thread is like trying to nail jelly to a tree.