Mastermind

Work Saw Specialist

Really simple stuff here fellers.....

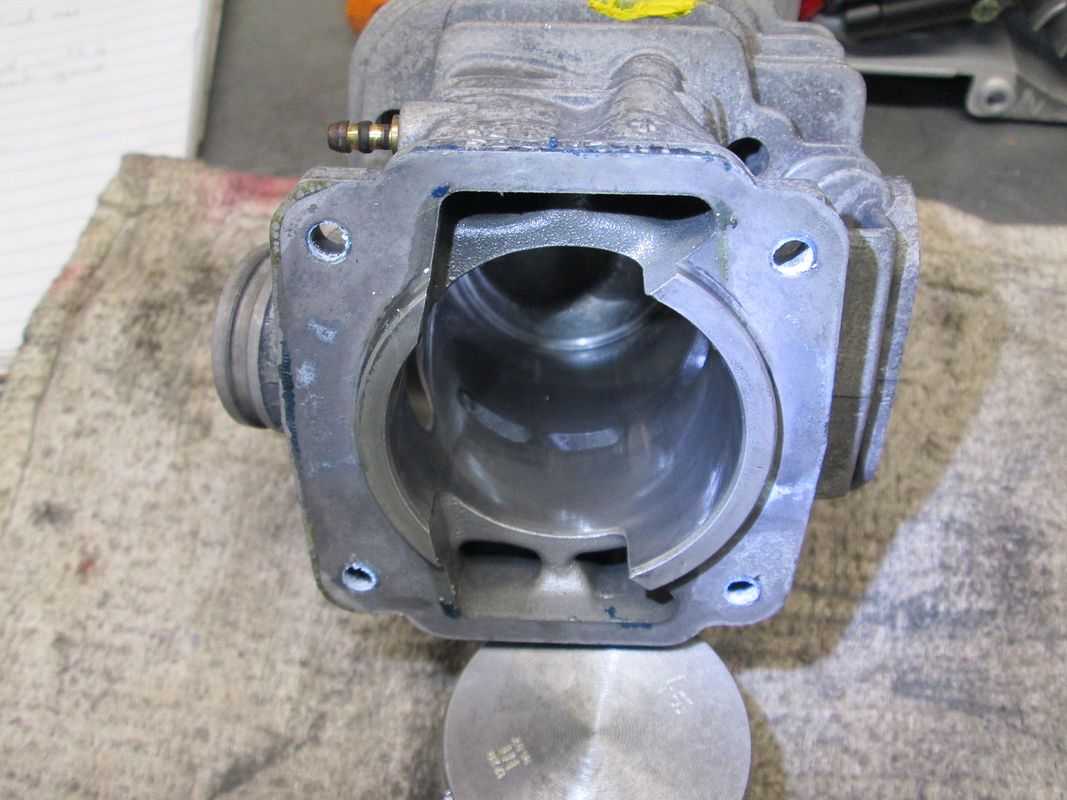

The victim......a NOS Solo 665.

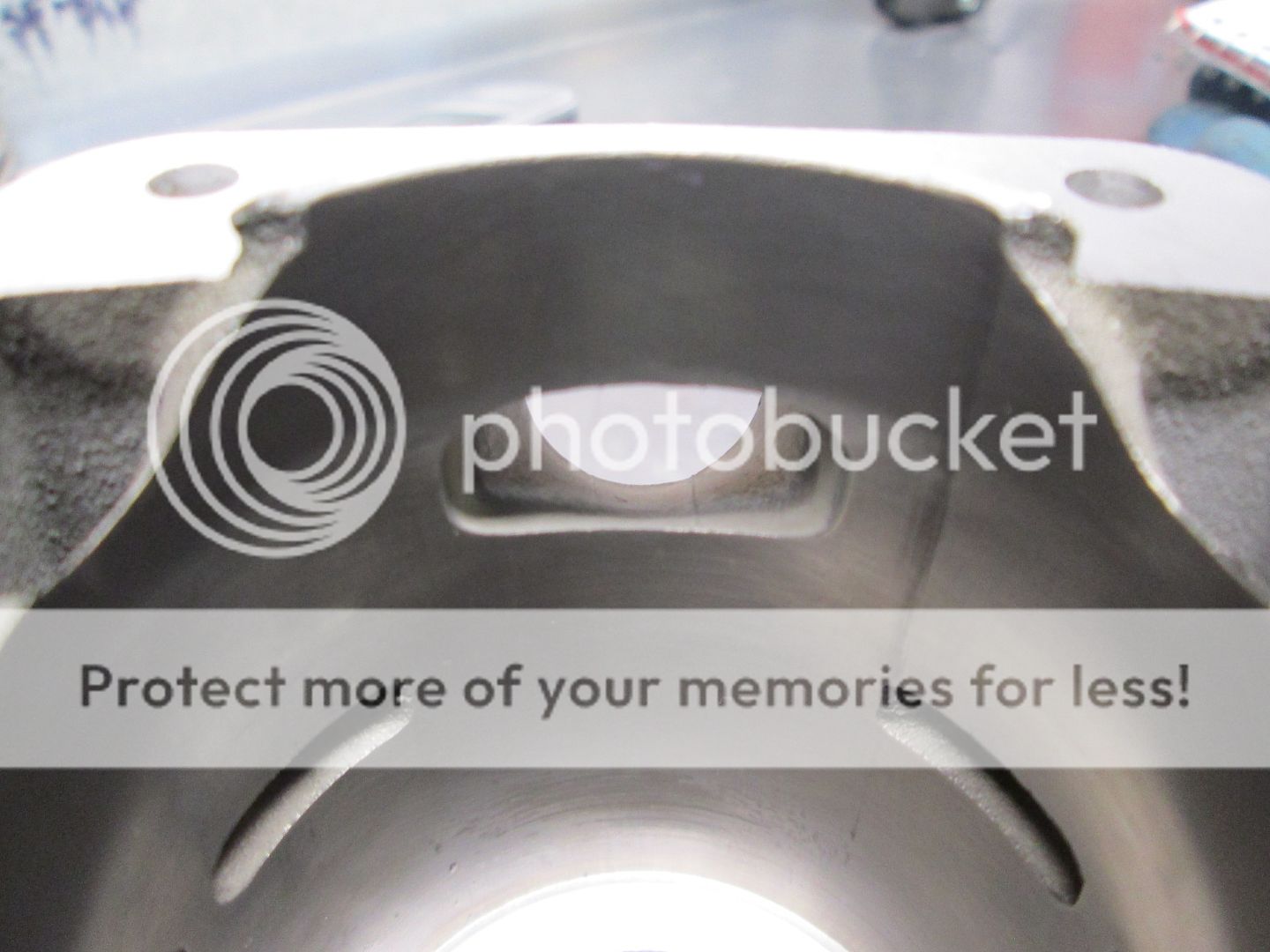

The top end.....

I like the 7910 top end on this saw for a few reasons.

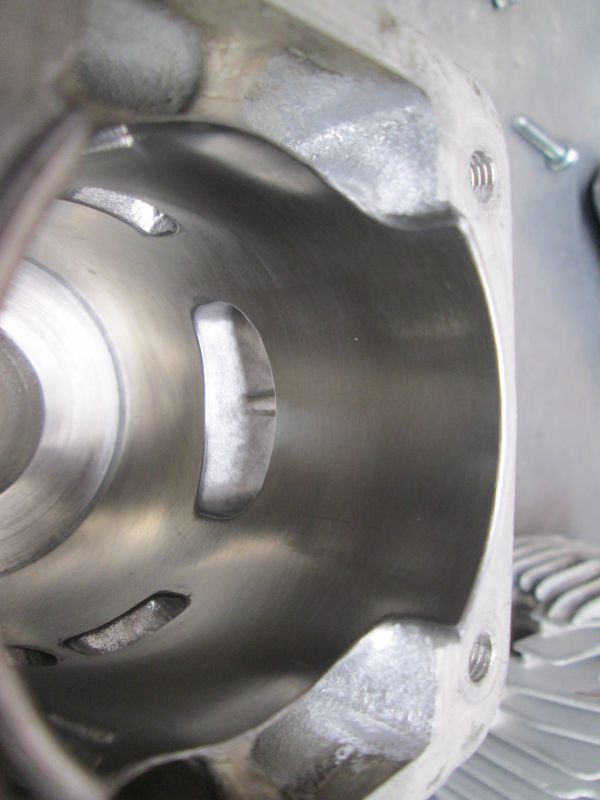

For one thing, the 7910 uses the new style light weight piston.

This piston seems to increase transfer....and that's a good thing.

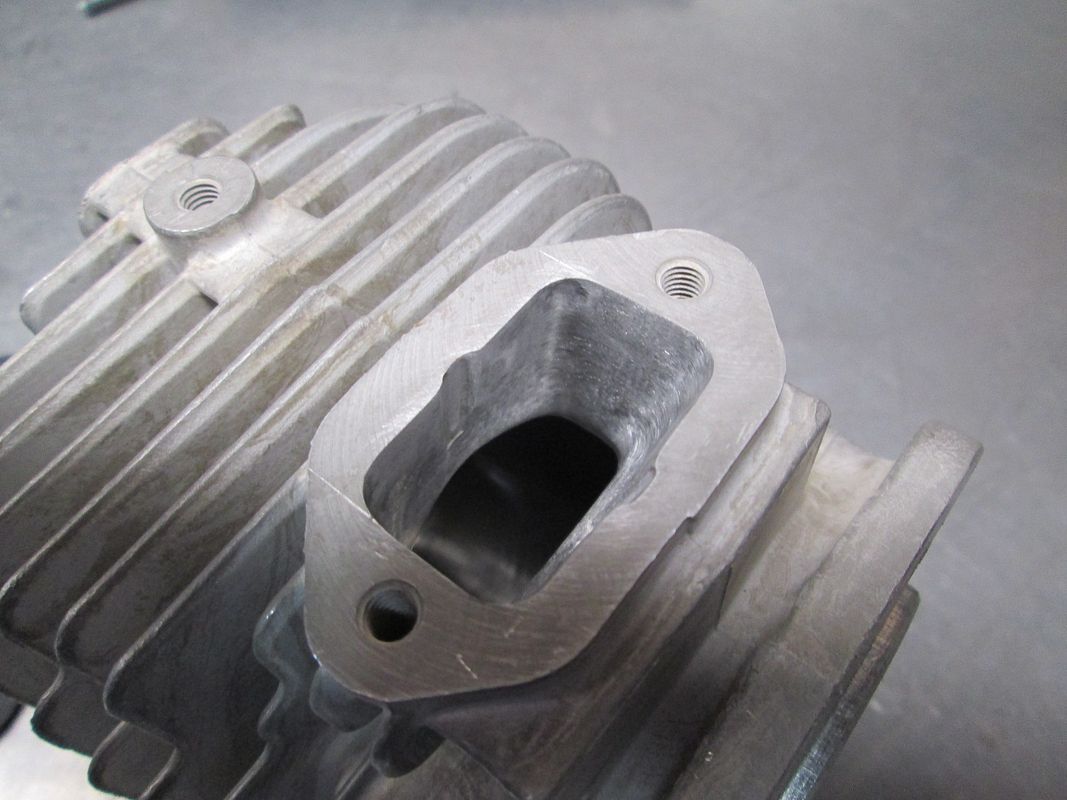

Now the Solo 665 had a 2mm longer stroke than the 7910, so you have a couple of choices. You can use a spacer under the jug, or you can cut the squish.

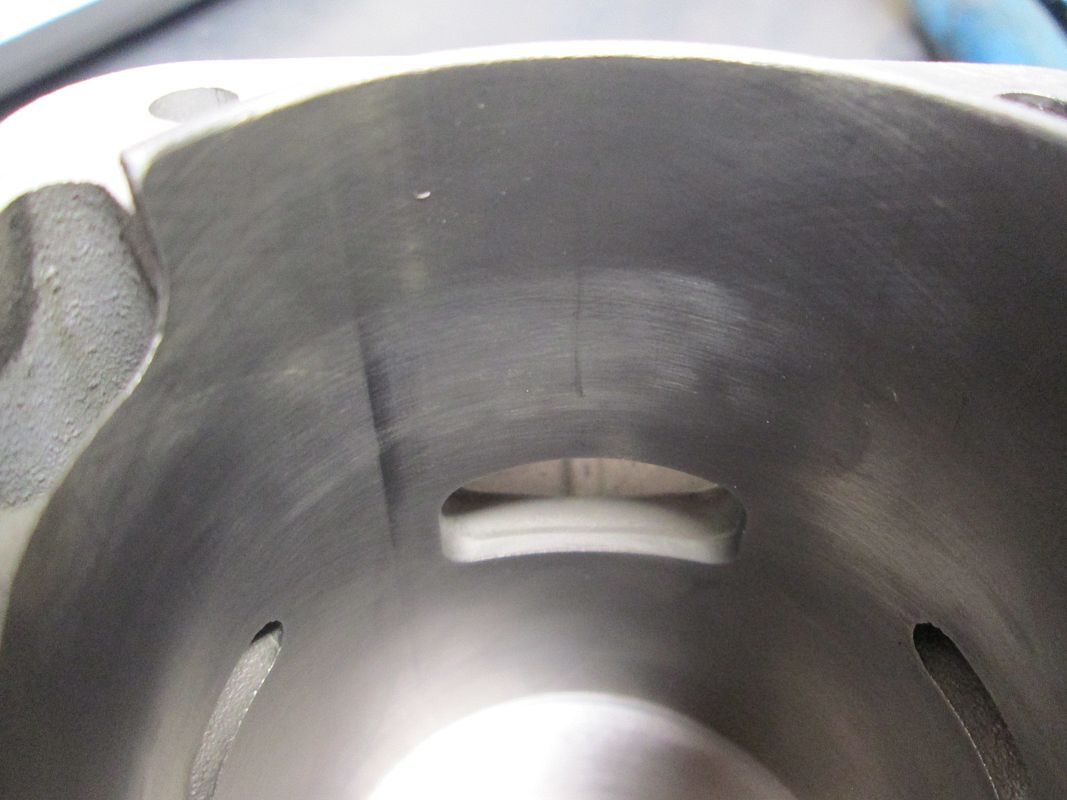

I chose to cut the squish. I'm building this saw as a 20" 8 pin rim saw. Not a cant cutting toy, but as a working saw that will be used in medium sized wood. By cutting the squish I was able to increase compression, and keep the cylinder base at the factory thickness for strength. I also like the way the timing numbers work out that way.

Now I took .060" out of the squish band, and used a Dolmar base gasket. The Dolmar base gasket is rubber coated metal VS the paper type gasket in the Solo. With that gasket in place the squish clearance is .018".

The victim......a NOS Solo 665.

The top end.....

I like the 7910 top end on this saw for a few reasons.

For one thing, the 7910 uses the new style light weight piston.

This piston seems to increase transfer....and that's a good thing.

Now the Solo 665 had a 2mm longer stroke than the 7910, so you have a couple of choices. You can use a spacer under the jug, or you can cut the squish.

I chose to cut the squish. I'm building this saw as a 20" 8 pin rim saw. Not a cant cutting toy, but as a working saw that will be used in medium sized wood. By cutting the squish I was able to increase compression, and keep the cylinder base at the factory thickness for strength. I also like the way the timing numbers work out that way.

Now I took .060" out of the squish band, and used a Dolmar base gasket. The Dolmar base gasket is rubber coated metal VS the paper type gasket in the Solo. With that gasket in place the squish clearance is .018".