Daninvan

ArboristSite Operative

I had this question buried in another, more interesting thread, so I thought I'd better post it separately with some specific details in the hopes of getting some suggestions.

I was milling with my Husky 2100 using a 36" bar, and the chain kept getting slack. After doing only about 4' of a 2' wide fairly soft maple, the chain was so loose it was almost ready to fall off the bar. It was also making a lot of unpleasant noises. The chain has been used before a couple times, was sharp, and I normally I would not have to tighten it at all. So I tightened up the tension adjustment screw, started another cut, and the same thing happened. So I stopped.

I think that the tension adjustment screw is working its way loose.

Here is what my tension adjuster assembly looks like. The screw head is out of the photo to the right, the big blurry thing in the middle is the nut with the pointy bit that slides into the hole in the bar. It appears that there is some kind of captured split washer on the right, I guess that prevents the assembly from sliding out?

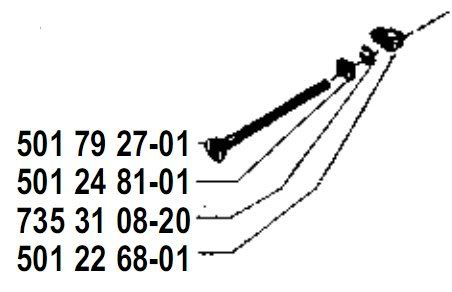

Here is what I copied from a Husky 2100 manual. The part ending in 27-01 is the screw, and 68-01 is the nut with the pointy bit on it. Unfortunately the picture quality is poor so it is hard to see what the other parts are. I am guessing from memory of another saw I took apart that 81-01 is a plastic/fibre square nut, and 8-20 I really don't know what it is.

So basically after all that I am looking for some ideas on what the problem might be.

Related specific questions might be, did I copy the right manual, how come I seem to have only three parts in my assembly and the manual shows four, and how come I have a split captured washer that the manual doesn't show. Or maybe my assembly is fine and there is a problem elsewhere? Etc?

Dan

I was milling with my Husky 2100 using a 36" bar, and the chain kept getting slack. After doing only about 4' of a 2' wide fairly soft maple, the chain was so loose it was almost ready to fall off the bar. It was also making a lot of unpleasant noises. The chain has been used before a couple times, was sharp, and I normally I would not have to tighten it at all. So I tightened up the tension adjustment screw, started another cut, and the same thing happened. So I stopped.

I think that the tension adjustment screw is working its way loose.

Here is what my tension adjuster assembly looks like. The screw head is out of the photo to the right, the big blurry thing in the middle is the nut with the pointy bit that slides into the hole in the bar. It appears that there is some kind of captured split washer on the right, I guess that prevents the assembly from sliding out?

Here is what I copied from a Husky 2100 manual. The part ending in 27-01 is the screw, and 68-01 is the nut with the pointy bit on it. Unfortunately the picture quality is poor so it is hard to see what the other parts are. I am guessing from memory of another saw I took apart that 81-01 is a plastic/fibre square nut, and 8-20 I really don't know what it is.

So basically after all that I am looking for some ideas on what the problem might be.

Related specific questions might be, did I copy the right manual, how come I seem to have only three parts in my assembly and the manual shows four, and how come I have a split captured washer that the manual doesn't show. Or maybe my assembly is fine and there is a problem elsewhere? Etc?

Dan