A "Steel" ,Steal? Not a Stihl but probably the best puzzle you will ever buy.... and useful when done.Well, $98.89...so call it $100. Total for the kit and shipping is $240.88

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Huztl MS660

- Thread starter Kyler Monares

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I would venture there is a much wider market for a smaller kit saw. MS360, 440. Speaking Craigslist here.

Kyler Monares

ArboristSite Operative

Your the guy I have been watching!? Just read your signature.A "Steel" ,Steal? Not a Stihl but probably the best puzzle you will ever buy.... and useful when done.

Did you buy the complete kits from Huztl or individual parts from them off eBay?

Your the guy I have been watching!? Just read your signature.

Did you buy the complete kits from Huztl or individual parts from them off eBay?

Did both. When I first did this they had not packaged a complete parts kit. Some folks were already selling complete built saws. I wanted to put together my own for my use. And in the beginning for me the hardest part was finding the detail parts and hardware. Discovered "devonshire" a eBay store for the screws & stuff. But with the kits it's got to save a pile of r&d time! Even if u have to pitch out some of the parts included...the time savings has to make it worth whileYour the guy I have been watching!? Just read your signature.

Did you buy the complete kits from Huztl or individual parts from them off eBay?

Also look in the hotsaw/modded work saw thread as I'm not the only one who has done this. There is a thread for those who took this route.

backhoelover

Free service manuals and service tool info

I might have to give huztl another try. seem like maybe I just got unlucky a couple times . So y'all use a huztl Cylinder with a meteor?

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$39.99

$79.99

SPEED FORCE Kindling Splitter Log Splitter FireWood Splitter Power Log Splitter, Long Life CAST Steel Blade, Black (XL)

SpeedForceUSA

$14.97

$19.99

Dremel A679-02 Sharpening Attachment Kit, For Sharpening Outdoor Gardening Tools, Chainsaws, and Home DIY Projects,

Amazon.com

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$213.07

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$27.99 ($0.23 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

backhoelover

Free service manuals and service tool info

Also do y'all still use there stuff for stuff that run 6-8 hr a day

Definitive Dave

wanna-be saw racer, saw hoarder, parts whore

- Joined

- Jul 27, 2013

- Messages

- 2,118

- Reaction score

- 5,088

Shoutout to Weimedog a mofo that speaks truth to power!!

A couple years ago we sold a complete FT 660 kit with a few OEM parts on Ebay they sold in spurts. None for a month and then three in a week and we were out of stock for a month till we got all the parts back in stock and then nothing for a month and then bam 5 in a week.

We sold them for @550 as best I can remember and made about $65 profit at the time. Shipping 20 pounds twice is expensive.

We built and sold maybe a dozen on Craigslist making sure every customer understood what they were for @$650.

I sold at least three to a local tree service who abused them just like the real deal and clutches and sprocket rims seemed to wear out quicker, but not crazy fast and certainly an acceptable life-span for the difference in price.

I started selling kits to a couple of local builders/flippers who buy parts from me.

The last batch I sold were 5 to one guy and three of them had the issue @weimedog described with the BB top end needing clearancing to fit properly. Of course the fitmet was so close that everything turned fine by hand but began to clatter at running speed as parts heated up and broke.

We also sold 361 and 360 kits successfully to tree services and on the Ebay.

The margins were too small for the amount of labor involved.

I would say as long as you count on spending a total of $400 you can build a pretty darn decent Aftermarket MS660 Clone.

I warn strongly against buying them preassembled (same with 260, 360, 361 and the 346, 372) they are built sweatshop assembly line style with no testing or quality control it's 50/580 you get one that even starts out of the box.

Building a Clone 660 or 361 is pretty fun and rewarding and you will likely end up with a saw that feels about 92.1% like the real deal.

The tensioner is hinky but 1/6th the price of Stihl, if you assemble it with lube and the inner side plate and then work it from end to end with a big honkin' screwdriver before going any further, you have a strong chance it will be fine.

The gears are forced to find the mesh this way and if it makes it from end to end it should be trouble free forever. If it wont go you can order a new one before the saw is all assembled.

Am carbs for the 660 are a mixed bag of mostly "Meh".

Bosch or NGK plug and a good carb are big improvements along with at least Caber rings, preferably a meteor piston or better yet p/c.

Dave

I wouldn't really run one 6-8 hours a day and I think most guys that run a saw that much are pros and might prefer the real deal even if just for the placebo effect.

A couple years ago we sold a complete FT 660 kit with a few OEM parts on Ebay they sold in spurts. None for a month and then three in a week and we were out of stock for a month till we got all the parts back in stock and then nothing for a month and then bam 5 in a week.

We sold them for @550 as best I can remember and made about $65 profit at the time. Shipping 20 pounds twice is expensive.

We built and sold maybe a dozen on Craigslist making sure every customer understood what they were for @$650.

I sold at least three to a local tree service who abused them just like the real deal and clutches and sprocket rims seemed to wear out quicker, but not crazy fast and certainly an acceptable life-span for the difference in price.

I started selling kits to a couple of local builders/flippers who buy parts from me.

The last batch I sold were 5 to one guy and three of them had the issue @weimedog described with the BB top end needing clearancing to fit properly. Of course the fitmet was so close that everything turned fine by hand but began to clatter at running speed as parts heated up and broke.

We also sold 361 and 360 kits successfully to tree services and on the Ebay.

The margins were too small for the amount of labor involved.

I would say as long as you count on spending a total of $400 you can build a pretty darn decent Aftermarket MS660 Clone.

I warn strongly against buying them preassembled (same with 260, 360, 361 and the 346, 372) they are built sweatshop assembly line style with no testing or quality control it's 50/580 you get one that even starts out of the box.

Building a Clone 660 or 361 is pretty fun and rewarding and you will likely end up with a saw that feels about 92.1% like the real deal.

The tensioner is hinky but 1/6th the price of Stihl, if you assemble it with lube and the inner side plate and then work it from end to end with a big honkin' screwdriver before going any further, you have a strong chance it will be fine.

The gears are forced to find the mesh this way and if it makes it from end to end it should be trouble free forever. If it wont go you can order a new one before the saw is all assembled.

Am carbs for the 660 are a mixed bag of mostly "Meh".

Bosch or NGK plug and a good carb are big improvements along with at least Caber rings, preferably a meteor piston or better yet p/c.

Dave

I wouldn't really run one 6-8 hours a day and I think most guys that run a saw that much are pros and might prefer the real deal even if just for the placebo effect.

BTarb24

ArboristSite Member

After feeling the sting Dave mentioned on wholesale pricing, I ordered one. I made a list and am going oem on gaskets , seals, bearings, all rings, fuel and oil hose and that came to about $150. I have yet to receive the kit so my list could decrease or increase. That means $400 in the saw, coming in quite a bit less than retail. I will wait for a bar and chain until the funs over.

The great part everybody can get in on this at a reasonable cost, and they should. Every father son, husband wife thats not over run with kids, explorer troops, old bored people, have some fun make something useful. Cut some wood when your done.

The great part everybody can get in on this at a reasonable cost, and they should. Every father son, husband wife thats not over run with kids, explorer troops, old bored people, have some fun make something useful. Cut some wood when your done.

ChoppyChoppy

Tree Freak

Also do y'all still use there stuff for stuff that run 6-8 hr a day

Yup.

BTarb24

ArboristSite Member

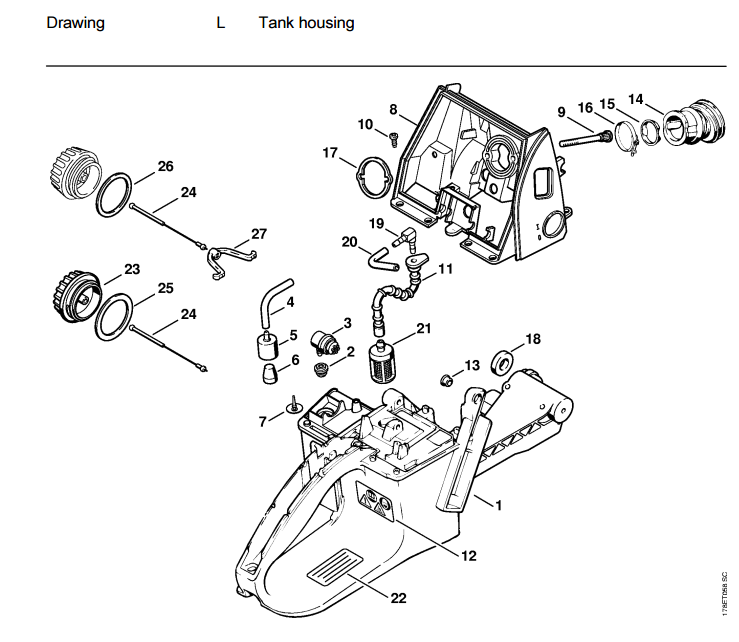

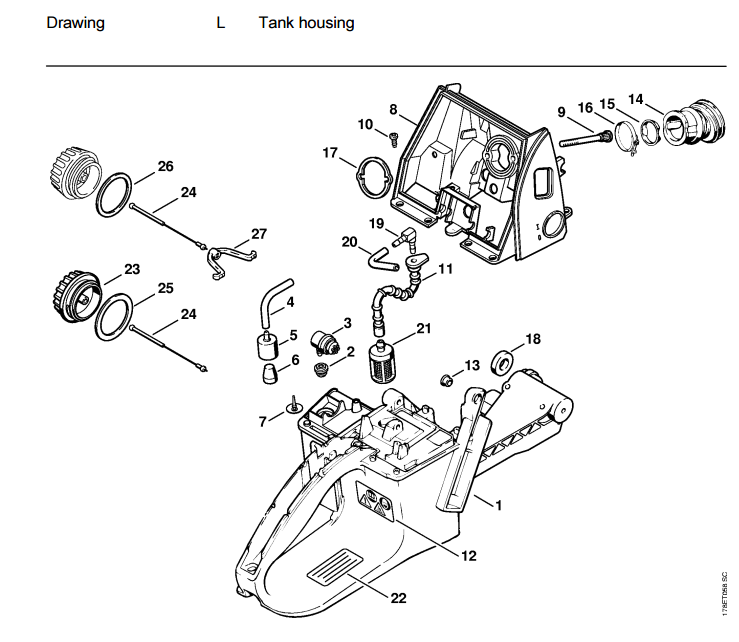

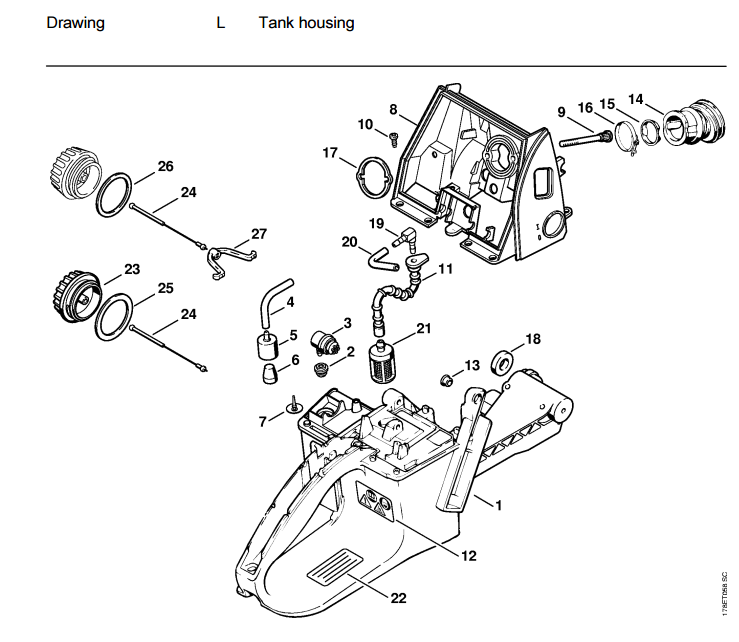

I wasn't sure if the kit was going to come with a breakapart to reference during assembly so i went off on a hunt to find one. Here's one that I stumbled across that seems pretty complete. I figured I'd share it for the other guys that may try to build the kit:

I attached it to this post and have it on my google drive:

https://drive.google.com/open?id=0B9GpQVviuibsajhPV0dFbDRDcEk

It's a 46-page pdf breakapart that seems to contain every screw and pin on the saw. It also spans the various version variations of the 660, which may be useful for those refurbing an older model. Here's a quick screenie from one of the pages:

I attached it to this post and have it on my google drive:

https://drive.google.com/open?id=0B9GpQVviuibsajhPV0dFbDRDcEk

It's a 46-page pdf breakapart that seems to contain every screw and pin on the saw. It also spans the various version variations of the 660, which may be useful for those refurbing an older model. Here's a quick screenie from one of the pages:

Attachments

motorman1

ArboristSite Operative

Man, I'm torn here. I've only been building saws based upon mostly OEM main parts, with a few "high quality" AM parts thrown in. Think Meteor piston / Caber rings and Ebay AM bearings. Everything else I've used thus far has been either new OEM, or good used OEM. I've done well getting them to run, but haven't really made a nickel on any, not counting for labor, as saw rebuilding is still a hobby to me and I'm fairly slow at it. I wish you well and will be following this thread, as I too have wondered about those nearly 100% knock-off kits. Good luck and please continue to post your results / progress.

Kyler Monares

ArboristSite Operative

Awsome!!! Thanks for the break apart!!!!!!!!I wasn't sure if the kit was going to come with a breakapart to reference during assembly so i went off on a hunt to find one. Here's one that I stumbled across that seems pretty complete. I figured I'd share it for the other guys that may try to build the kit:

I attached it to this post and have it on my google drive:

https://drive.google.com/open?id=0B9GpQVviuibsajhPV0dFbDRDcEk

It's a 46-page pdf breakapart that seems to contain every screw and pin on the saw. It also spans the various version variations of the 660, which may be useful for those refurbing an older model. Here's a quick screenie from one of the pages:

Ordered my 660 kit today

Kyler Monares

ArboristSite Operative

I will report as well. However you will probably beat me to it because you ordered several days ago

BTarb24

ArboristSite Member

Awesome! It looks like we're going to end up with a handful of people building it at once.  I'll be sure to post my progress along with any issues/tips I come across. Thus far I've only done small engine carb work, so this will be my first small engine build. I've done full car engine builds so I'm hoping that experience is enough to get through it. I'm looking forward to the new learning experience and challenge -- and to have a larger chainsaw

I'll be sure to post my progress along with any issues/tips I come across. Thus far I've only done small engine carb work, so this will be my first small engine build. I've done full car engine builds so I'm hoping that experience is enough to get through it. I'm looking forward to the new learning experience and challenge -- and to have a larger chainsaw

I put my order in on Sept 3. I haven't received a shipping notice yet. Sadly, i had assumed it had been packed and shipped the following day but given trboxman's post, mine is probably still sitting in a warehouse somewhere.

I put my order in on Sept 3. I haven't received a shipping notice yet. Sadly, i had assumed it had been packed and shipped the following day but given trboxman's post, mine is probably still sitting in a warehouse somewhere.

wow...wish you all were closer! We could have a HZ660 GTG to compare notes and spend an afternoon tuning, debugging and tweaking...looking forward to how your projects progress. Pics and video's would be nice!

I ran my 56mm for a while this weekend, had to tweak the carb a bit as it was a bit fat on the low side (stalling after a minute or so idling) and a bit lean on top. A warm and humid day. A 15 second tweak later it was happy and so was I. Sometimes you forget what a crisp 90cc plus saw is like. These things will remind you...

I ran my 56mm for a while this weekend, had to tweak the carb a bit as it was a bit fat on the low side (stalling after a minute or so idling) and a bit lean on top. A warm and humid day. A 15 second tweak later it was happy and so was I. Sometimes you forget what a crisp 90cc plus saw is like. These things will remind you...

I put my order in on Sept 3. I haven't received a shipping notice yet. Sadly, i had assumed it had been packed and shipped the following day but given trboxman's post, mine is probably still sitting in a warehouse somewhere.

I didn't get a shipping notice, I got the status from there site under My Account-->Order History--right hand side of the page, middle way down is a "Status" line. Underneath "Status" are two icons, click on the icon that looks like a magnifying glass over a document. That will bring up the details of your order. The tracking number on mine doesn't seem to map to any of the standard Chinese shipping services...but I'm not really worried about it either. It'll show up when it shows up.

I've been busy getting my shop and tooling ready (have to dig out my 20ton press

Similar threads

- Replies

- 32

- Views

- 3K