My friend’s Dad used to sharpen all of his chains but his health was failing at age 84 and he asked me to take over using the Oregon 511A that his Dad had bought several years ago. I agreed and he unbolted the machine from his workbench and gave it to me last week along with the three grinding disks and a cleaning brick.

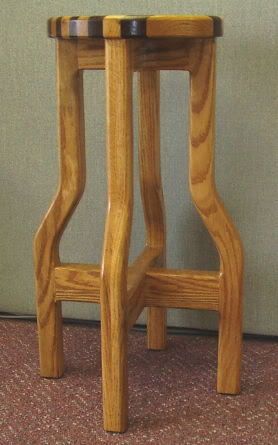

I decided to mount the machine on a portable hardwood assembly so that we could use it in both of our shops. First, I checked the instructions. Oregon says “Mount machine at chest height for best visibility and ease of operation.” I imagine 95% of all of these machines are never mounted that high unless wall mounted, so I decided to compromise with the chains resting at about 46” above the floor and secured inside my bench vise jaws.

The basic design is simply a vertical mounting plate and a cantilever shelf supported on each side. Using oak throughout, I used a 7-1/2” x 15” vertical plate, 3/4” thick, and then switched to 1” thick stock for the shelf and supports.

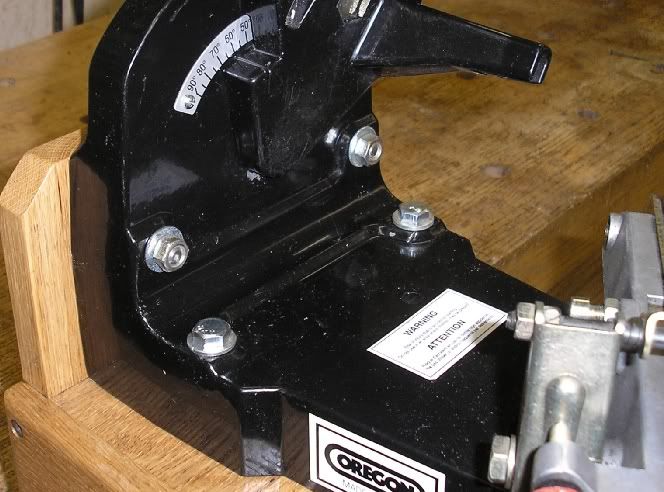

I plowed out a shallow dado groove into the plate to position the shelf and rabbet cut the side supports to hold the shelf dead flat and rock solid. The outer edge of the shelf stops just short of the tabs under the machine and is square to the vertical plate.

Before assembly, I drilled holes to accept four 5/16” bolts for securing the 511A to the assembly rather than use the two lag screws that came with the unit. I tapped threads into the shelf and counter-bored 1/8”deep recessed holes in the back of the mounting plate for carriage bolt heads. The recessed holes would allow the plate to be wall mounted flush, so I also pre-drilled a pair of mounting holes screws, centered on the plate and about a foot apart. Two coats of varnish completed the woodwork.

To mount the 511A to the assembly, I set the horizontal carriage bolts first using a washer and a nut with each, thus producing studs. I then secured the 511A to the studs with two more nuts and washers.

Finally, I dropped in the vertical bolts into the threaded holes to complete the assembly. Using four fasteners may have been overkill, but it sure seemed to firm it all up.

Now I’m ready to sharpen some chains with this gizmo.

If any of you have any tips for a novice using this machine, I still have a good ear. Thanks for looking.

I decided to mount the machine on a portable hardwood assembly so that we could use it in both of our shops. First, I checked the instructions. Oregon says “Mount machine at chest height for best visibility and ease of operation.” I imagine 95% of all of these machines are never mounted that high unless wall mounted, so I decided to compromise with the chains resting at about 46” above the floor and secured inside my bench vise jaws.

The basic design is simply a vertical mounting plate and a cantilever shelf supported on each side. Using oak throughout, I used a 7-1/2” x 15” vertical plate, 3/4” thick, and then switched to 1” thick stock for the shelf and supports.

I plowed out a shallow dado groove into the plate to position the shelf and rabbet cut the side supports to hold the shelf dead flat and rock solid. The outer edge of the shelf stops just short of the tabs under the machine and is square to the vertical plate.

Before assembly, I drilled holes to accept four 5/16” bolts for securing the 511A to the assembly rather than use the two lag screws that came with the unit. I tapped threads into the shelf and counter-bored 1/8”deep recessed holes in the back of the mounting plate for carriage bolt heads. The recessed holes would allow the plate to be wall mounted flush, so I also pre-drilled a pair of mounting holes screws, centered on the plate and about a foot apart. Two coats of varnish completed the woodwork.

To mount the 511A to the assembly, I set the horizontal carriage bolts first using a washer and a nut with each, thus producing studs. I then secured the 511A to the studs with two more nuts and washers.

Finally, I dropped in the vertical bolts into the threaded holes to complete the assembly. Using four fasteners may have been overkill, but it sure seemed to firm it all up.

Now I’m ready to sharpen some chains with this gizmo.

If any of you have any tips for a novice using this machine, I still have a good ear. Thanks for looking.