It's only as good as the installer and the operator.I go back to what I said my 1100 dollar epa furnace keeps it warm in here after I figured out how to use it. For the cost of a kuuma it should do amazing things.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kiuma VF 100 not heating my house! Disappointed!

- Thread starter bropp

- Start date

Help Support Arborist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

It's only as good as the installer and the operator.

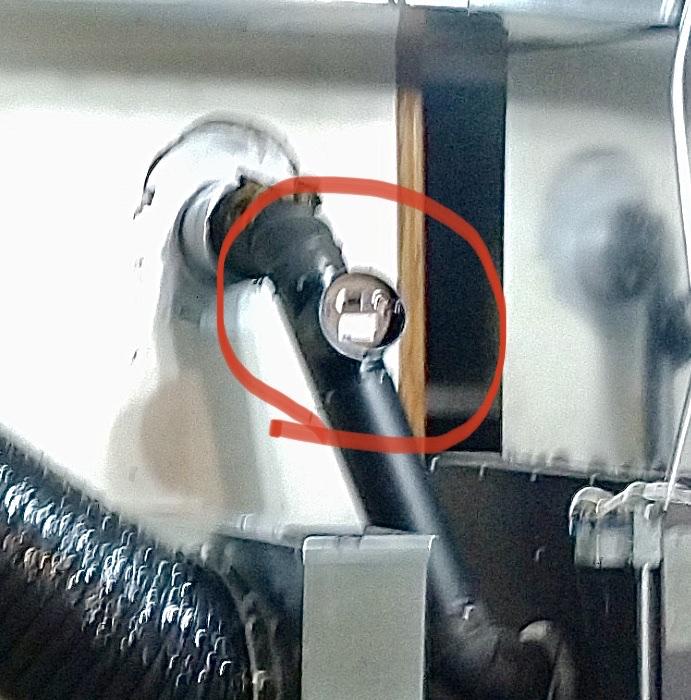

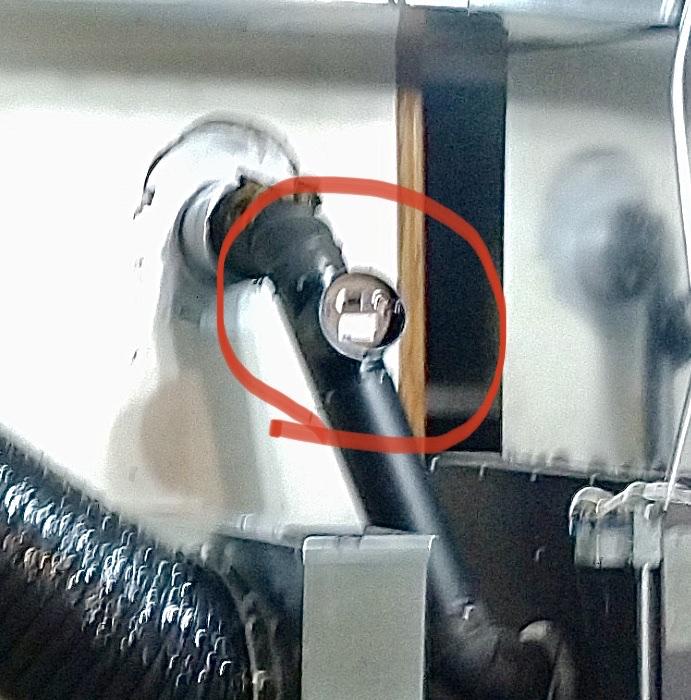

Personally I'd throw some foil over the baro and see what that does. I've never liked them and on a furnace that controls air inlet based on burn temp theres no need for one. And it looks to be installed to wide open allowing minimal draft.

These companies make you think you throw 5 pieces of wood in and 10 hours later you are still heating with hot heat. Many may like the kuuma but it's to much for me I like to keep it simple.

Personally I'd throw some foil over the baro and see what that does. I've never liked them and on a furnace that controls air inlet based on burn temp theres no need for one. And it looks to be installed to wide open allowing minimal draft.

Don't follow this guys advice.

Don't follow this guys advice.  I can almost guaranty the furnace is burning and functioning properly, as long as his draft is kept in check by way of the BD.

I can almost guaranty the furnace is burning and functioning properly, as long as his draft is kept in check by way of the BD.I asked for some temperature data points on the other forum.

These companies make you think you throw 5 pieces of wood in and 10 hours later you are still heating with hot heat. Many may like the kuuma but it's to much for me I like to keep it simple.

Depends on how big the pieces are. If the pieces are 12-15 lbs each, yes, 10 hours later you will definitely still have heat. Loaded 99.4lbs last weekend in my Kuuma VF100 when we were gone and I had almost 21.5 hours of continuous blower run time. See my graphs below of plenum vs time and stack temp vs time. I do have a speed controlled blower, so my blower speeds increase as plenum temps increase and decrease as plenum temps decrease.

Outside temps were hovering around 15° throughout the burn at night and the house was steady at 72°, until late on Sunday afternoon when supply temps tapered off. LP furnace stayed off until sometime Sunday night. LP thermostat was set to 62°. Kuuma was set on minimum burn.

Interpreting the graphs below.

- Total continuous blower runtime of almost 21.5 hours (6:10pm on Sat till about 3:30pm on Sunday).

- It was doing the c-1-c thing soon after loading till about 7:45pm or so

- It was on pilot continuously from about 7:45pm to 11:00pm.

- It was doing the c-1-c thing again from around 11:00pm till about 3:00am Sunday or so

- It stayed on '1' from 3am till about 8:15am

- It was doing the 1-2-1 thing from about 8:15am through 10:30am.

- Stayed on '2' from about 10:30am to 11:30am

- Went to '3' for good at around 11:30am

- Blower turned off at about 3:30pm Sunday....~96° plenum temp

- It went to 'C' (cold) around 6:15pm.

c: damper is fully closed and solely running on pilot air (when computer is set on minimum burn, it happens when internal firebox temps reach around 1,090°)

1: damper is slightly open

2: damper is open a bit more

3: damper is fully open

C: damper is fully closed due to a "cool" firebox. It's more like a warm to the touch firebox.

Don't follow this guys advice.

I can almost guaranty the furnace is burning and functioning properly, as long as his draft is kept in check by way of the BD.

I asked for some temperature data points on the other forum.

Depends on how big the pieces are. If the pieces are 12-15 lbs each, yes, 10 hours later you will definitely still have heat. Loaded 99.4lbs last weekend in my Kuuma VF100 when we were gone and I had almost 21.5 hours of continuous blower run time. See my graphs below of plenum vs time and stack temp vs time. I do have a speed controlled blower, so my blower speeds increase as plenum temps increase and decrease as plenum temps decrease.

Outside temps were hovering around 15° throughout the burn at night and the house was steady at 72°, until late on Sunday afternoon when supply temps tapered off. LP furnace stayed off until sometime Sunday night. LP thermostat was set to 62°. Kuuma was set on minimum burn.

Interpreting the graphs below.

- Total continuous blower runtime of almost 21.5 hours (6:10pm on Sat till about 3:30pm on Sunday).

- It was doing the c-1-c thing soon after loading till about 7:45pm or so

- It was on pilot continuously from about 7:45pm to 11:00pm.

- It was doing the c-1-c thing again from around 11:00pm till about 3:00am Sunday or so

- It stayed on '1' from 3am till about 8:15am

- It was doing the 1-2-1 thing from about 8:15am through 10:30am.

- Stayed on '2' from about 10:30am to 11:30am

- Went to '3' for good at around 11:30am

- Blower turned off at about 3:30pm Sunday....~96° plenum temp

- It went to 'C' (cold) around 6:15pm.

c: damper is fully closed and solely running on pilot air (when computer is set on minimum burn, it happens when internal firebox temps reach around 1,090°)

1: damper is slightly open

2: damper is open a bit more

3: damper is fully open

C: damper is fully closed due to a "cool" firebox. It's more like a warm to the touch firebox.

View attachment 789831

View attachment 789830

I'm only saying the foil thing because his baro appears to be pointing up in the air and I'm assuming it's running so correcting that would be hard.

Sounds like you have your kuuma working great. From reading how yours operates it sounds like it's hard to not make consistant heat. Hows the OP getting a 90 degree plenum temp and 70 degree air out of the registers? I had 101 coming out of mine last night and that's with the furnace air being mixed into my existing ductwork.

Hows the OP getting a 90 degree plenum temp and 70 degree air out of the registers?

That's the question of the day. This is what I asked on the other forum.

All of us are just guessing at this point as we have very few data points to go off of. We need to know your return air temp and your plenum temp....so we can see what your dT is. Register temps taken at the same time of the other two. Garage temp (looks to be the garage anyway), where the furnace is located. Assuming the space you are heating is ABOVE the furnace....seeing you stated the garage is the lower level.

For some of us, wood furnaces are not just a plug and play appliance. Some setups/houses need some tweaking done to the return/supply air to get them to perform at max performance and some don't. I was one of them who did.

I would also like to know if the furnace is going to pilot ('c') at whatever burn set point (low to high) you have the computer set at? If the computer is going to pilot, it's meeting internal firebox temps for the level of burn the computer is set for and burning the wood as designed.

If he's sucking in 50° - 60° air, his supply/plenum temps should be around 90° - 100°. A dT of 35°-40° is normal. Right after I installed mine, out of the "box" and before any tweaks to my return/supply air, I was taking in 65° air and my plenum temps were right around 100° with the blower on low and the Kuuma on low. Blower on high with Kuuma on high.....I was seeing ~105° plenum temps.

This heated our large volume log cabin style home fine, as long as temps didn't drop much below 10°. Before we burned wood, we used, on average over 5 winters, between 1,200 - 1,300 gallons of LP a year to keep this place 68°. So our house is not exactly efficient either.

After my return air/supply tweaks, I'm now taking in 80° - 83° air and my plenum temps are 115° - 118° with the Kuuma on low. 120° - 124° with the Kuuma on high. I slowed my blower WAY down by way of the speed controller, as this house likes lower volumes of warmer air vs higher volumes of "cooler" air. The speed controller speeds the blower up when plenum temps rise and slows the blower down when they fall. So when the plenum temps are 124°, it's putting a lot more of that 124° air into the home vs when plenum temps are 115°.

The results are now the Kuuma heats this place much easier than it did before. I was able to heat it last January with wood only when we had 6 or 7 days straight of brutal cold....hit -37°F one night. All I did was change how the air was being delivered to the house, as the furnace was always burning the wood just fine.

I would also like to add, back when I spoke to Daryl (the owner) for the first time when looking into the Kuuma, he wanted to know details of our house and LP consumption. After telling him he flat out told me that I'm lucky the house is not any bigger and that it may not heat the house fully in real cold weather. He said it should handle most of it though and if the LP runs a bit on the real cold mornings, so be it. Daryl was very straight forward with me.

That's the question of the day. This is what I asked on the other forum.

I would also like to know if the furnace is going to pilot ('c') at whatever burn set point (low to high) you have the computer set at? If the computer is going to pilot, it's meeting internal firebox temps for the level of burn the computer is set for and burning the wood as designed.

If he's sucking in 50° - 60° air, his supply/plenum temps should be around 90° - 100°. A dT of 35°-40° is normal. Right after I installed mine, out of the "box" and before any tweaks to my return/supply air, I was taking in 65° air and my plenum temps were right around 100° with the blower on low and the Kuuma on low. Blower on high with Kuuma on high.....I was seeing ~105° plenum temps.

This heated our large volume log cabin style home fine, as long as temps didn't drop much below 10°. Before we burned wood, we used, on average over 5 winters, between 1,200 - 1,300 gallons of LP a year to keep this place 68°. So our house is not exactly efficient either.

After my return air/supply tweaks, I'm now taking in 80° - 83° air and my plenum temps are 115° - 118° with the Kuuma on low. 120° - 124° with the Kuuma on high. I slowed my blower WAY down by way of the speed controller, as this house likes lower volumes of warmer air vs higher volumes of "cooler" air. The speed controller speeds the blower up when plenum temps rise and slows the blower down when they fall. So when the plenum temps are 124°, it's putting a lot more of that 124° air into the home vs when plenum temps are 115°.

The results are now the Kuuma heats this place much easier than it did before. I was able to heat it last January with wood only when we had 6 or 7 days straight of brutal cold....hit -37°F one night. All I did was change how the air was being delivered to the house, as the furnace was always burning the wood just fine.

I would also like to add, back when I spoke to Daryl (the owner) for the first time when looking into the Kuuma, he wanted to know details of our house and LP consumption. After telling him he flat out told me that I'm lucky the house is not any bigger and that it may not heat the house fully in real cold weather. He said it should handle most of it though and if the LP runs a bit on the real cold mornings, so be it. Daryl was very straight forward with me.

So based on that I go back to saying the ductwork is to big and the heat runs off the end dont help. If he has to have the blower on high to pressurize that size ductwork then on low blower it probably doesnt move any air. Smaller ductwork better heat runs and lower blower speed would probably put out the same amount of air from the registers but it would be warmer.

I will say I insulated the concrete walls around my wood furnace and that space went from 60s when the furnace was running to 80s. I draw return directly from the basement since the manual says to. I haven't had any complaints about the 200$ i spent in foam board. Raise the return temp and that should directly affect the supply temp.

$202.29

Oregon Yukon Chainsaw Safety Protective Bib & Braces Trousers - Type A Protection, Dark Grey, Large

Express Shipping ⭐⭐⭐⭐⭐

$26.99 ($0.22 / Foot)

$29.99 ($0.25 / Foot)

VEVOR Double Braided Polyester Rope, 1/2 in x 120 ft, 48 Strands, 8000 LBS Breaking Strength Outdoor Rope, Arborist Rigging Rope for Rock Hiking Camping Swing Rappelling Rescue, Orange/Black

Amazon.com

$38.99 ($0.39 / Foot)

Arborist Rope Climbing Rope Swing for Tree(1/2in x 100ft) Logging Rope 48 Strands for Pull, Swing, Knot (Orange)

SDFJKLDI

$36.99

$59.99

SPEED FORCE Kindling Splitter-Log Splitter-FireWood Splitter–Power Log Splitter Blade Made from CAST Steel, Black Large

SpeedForceUSA

$337.83

$369.99

WEN Electric Log Splitter, 6.5-Ton Capacity with Portable Stand (56208)

Amazon.com

$215.05

$233.19

Weaver Leather WLC 315 Saddle with 1" Heavy Duty Coated Webbing Leg Straps, Medium, Brown/Red

Amazon.com

$39.99

$79.99

SPEED FORCE Kindling Splitter Log Splitter FireWood Splitter Power Log Splitter, Long Life CAST Steel Blade, Black (XL)

SpeedForceUSA

$63.99

ZELARMAN Chainsaw Chaps Apron Wrap 8-layer for Men/Women Loggers Forest Workers Protective Chain Saw Pants Adjustable

QUALITY GARDEN & HAND TOOLS

$14.97

$19.99

Dremel A679-02 Sharpening Attachment Kit, For Sharpening Outdoor Gardening Tools, Chainsaws, and Home DIY Projects,

Amazon.com

$79.99

ZELARMAN Chainsaw Chaps 8-layer Protective Apron Wrap Adjustable Chainsaw Pants/Chap for Loggers Forest Workers Class A

QUALITY GARDEN & HAND TOOLS

sunfish

Fish Head

This ^^^ 99% of the time its an install problem.Marshy is right. It's hardly ever the unit it's almost always the ducting, fan or draft.

homemade

Certified Chainsaw Tester

Notice how the damper is pointing to the sky. This should be rotated 90 degrees in the stove pipe. Then the damper hinge obviously needs to be level. That will spin in the damper housing.

brenndatomu

Hey you woodchucks, quit chucking my wood!

No, he is right...1080* F is the lowest temp (internally) that the computer will let the firebox go into "pilot" burn, (or "cruise" as the stove guys call it) and it only goes up from there...There's no way it's over 1100F. It would be slight red to dull red visually. That would be nearly over fire conditions. I would venture a guess that the stove manufacture never wants 1100F degrees or higher...

Notice how the damper is pointing to the sky. This should be rotated 90 degrees in the stove pipe. Then the damper hinge obviously needs to be level. That will spin in the damper housing.

This.

So my 2 cents would be to try spinning the baro to as close to vertical first, and then move on to try slower blower speed next. Either way you’ve came to the right place bropp. I’m just a Hotblast guy that drools over the vaporfire here year after year because of so many that it works well for. You’ll get it figured out. I may go that way yet myself but for now I’m ok with putting big loads in every 6 hours so I can catch up with what’s going on here while I get my next burn dialed in! Lol

OnTheRoad

Collector of shiny things.

- Joined

- Jan 24, 2014

- Messages

- 614

- Reaction score

- 615

Doesn't that ribbed ducting significantly reduce the amount of air passing through?

brenndatomu

Hey you woodchucks, quit chucking my wood!

Absolutely.Doesn't that ribbed ducting significantly reduce the amount of air passing through?

I dont think the OP is returning but it goes to show that a top of the line furnace needs a install from someone who knows what they are doing. It's not an hot blast that throws crazy heat and eats wood. The duct design and install of the furnace is very important.

OP hasn't been online since the 20th....assuming they figured out the issue and did not want to admit to the masses that it was install error.I dont think the OP is returning but it goes to show that a top of the line furnace needs a install from someone who knows what they are doing. It's not an hot blast that throws crazy heat and eats wood. The duct design and install of the furnace is very important.

Edit, I see over on hearth he was responding as late as Saturday and is making some headway by changing settings.

2003rubicon

New Member

Does anyone have some pictures of there vapor fire setup. I have one and it does heat real well if my house. I had a older wood furnace that cooked me out while chewing up the fire wood found this vapor fire for a steel but it doesn’t heat my house real well looking for some ideas with people that have had god luck

Similar threads

- Replies

- 4

- Views

- 373

- Replies

- 61

- Views

- 3K

- Replies

- 1

- Views

- 380