Continuing from the earlier post in this thread showing the inside of the 361 muffler and spark arrester issues.

The easiest solution to adding a port is simple to drill a hole and insert a tube. Covering this with a screen is a poor choice as the surface area of the screen is small. Stihl solved this problem on the BR400/420/340/380 series of blowers (as far back as 1992 on the BR 400) by inserting a tube of screen material into the pipe. It folds back over the pipe and is secured by a clip. The screen is many times the area of the outlet, so flow restriction even with some blockage is minimal.

This can be used on any almost any saw where you need a spark arrester and are adding a port (so long as you have room inside). You can of course choose not to fit it, but so long as the tube is the correct dimension, you have the option of putting it back in!

There are two basic sizes available: One fits over a 14mm OD (roughly 1/2 inch ID) pipe and the othe over a 16mm OD thin wall pipe. The picture shows the 14mm version. I'll have the 16mm version is a day or so and will likely use this as the pipe is thin wall 9/16 ID tube will work and is easier to find (for me).

Part numbers:

14mm version (BR420 etc blower)

Screen - 4203 141 9005 $5.56

Clip - 4203 141 6600 $2.00

16mm version (TS 400 Cut-off saw)

Screen - 4223 141 9000 $4.25

Clip - 4223 141 6600 $3.25

I did not need to tear the muffler apart to do this modification. The only reason I did was to educate myself on the internals and space constraints. In the future, it's just drill a hole at 45 degrees, grind the bottom of a short tube at 45 (so the screen has maximum area inside the muffer), and braze it on. For those of you intimidated by the thought of brazing, it is dead easy and can be done with Mapp gas available at your local hardware store.

The easiest way to drill a big hole at 45 degrees in thin metal is to use a uni-bit or one of the cheaper clones. They look like this :

Here's the muffler back together (heated the crimp area "red" and crimped it back together):

This is what the 14mm screen looks like inside the muffler. The 16mm is longer.

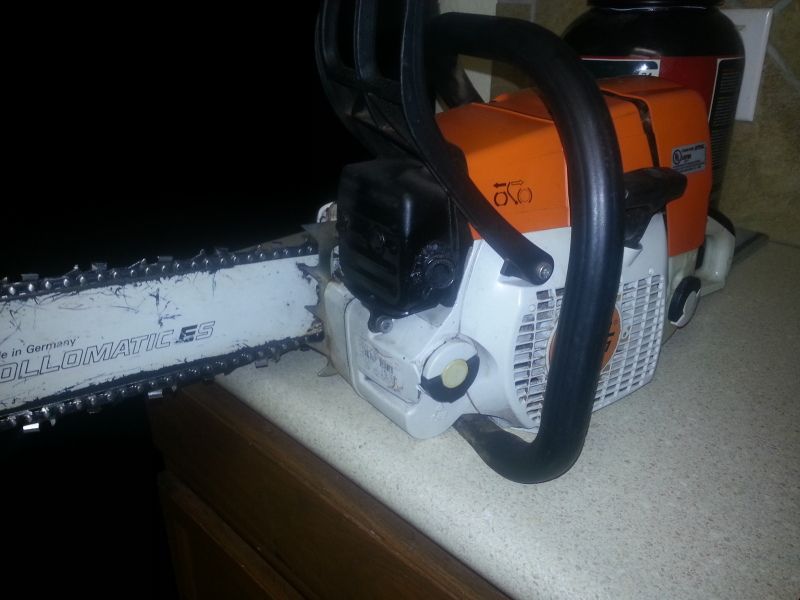

Here's the completed muffler on the saw. The factory spark arrester and exhaust port are unmodified. Heck you could even put it back to "factory" by plugging the new port!

One nice coat of matt exhaust paint and a quick bake (450F for an hour in the convection oven!) and it's one tough coating and ready for work. Hmmm, looks like factory stock to me.

Questions? Improvements?

I did a small vent on the oposite side with (5) 3/8" on the plate.