Hey there everyone,

Recently tackled a little cosmetic fix on a 2006 Husqvarna 55 top cover.

I got it off the Previous owner and it had a hole melted in a spot just above the muffler from it touching. (I think the owner ran the saw with the muffler loose and didn’t bother fixing it and it rattled around).

Selling this saw so I figured I’d make it look a little better, so this is what I did step by step to make that happen! It’s just a little experiment I thought might work so why not try

1-(cleaned top cover real good with cleaner and dish soap for final clean).

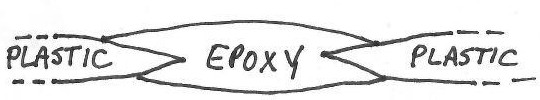

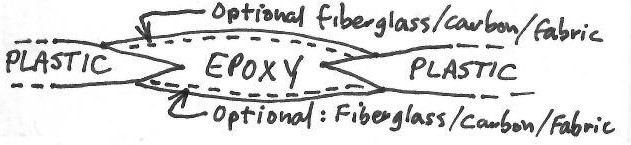

2-(rough up and texture area around hole so epoxy can stick).

3-(tape area and shape it accordingly so that the tape becomes the new surface that takes up the space of hole when tape comes off).

4-(mix epoxy and apply to affected area as needed and let cure then remove tape)

5-( [optional*] cover the affected area with a sticker so the patch job is covered up and then put back onto saw!).

Recently tackled a little cosmetic fix on a 2006 Husqvarna 55 top cover.

I got it off the Previous owner and it had a hole melted in a spot just above the muffler from it touching. (I think the owner ran the saw with the muffler loose and didn’t bother fixing it and it rattled around).

Selling this saw so I figured I’d make it look a little better, so this is what I did step by step to make that happen! It’s just a little experiment I thought might work so why not try

1-(cleaned top cover real good with cleaner and dish soap for final clean).

2-(rough up and texture area around hole so epoxy can stick).

3-(tape area and shape it accordingly so that the tape becomes the new surface that takes up the space of hole when tape comes off).

4-(mix epoxy and apply to affected area as needed and let cure then remove tape)

5-( [optional*] cover the affected area with a sticker so the patch job is covered up and then put back onto saw!).