93green12v

ArboristSite Operative

What kind of spacing should it have?As long as they don't rub on your I-beam and are a weak point in case something goes wonky........bolts are easier to replace then your I beam..........then go for it!

What kind of spacing should it have?As long as they don't rub on your I-beam and are a weak point in case something goes wonky........bolts are easier to replace then your I beam..........then go for it!

I was talking about the spacing where the push plate and I beam meet underneath.My ram is 14" long, has 5 bolts per side, about 2.75" spacing.

Speaking of strainers, I have read some people don't run one and some people do. Honestly what are they going to strain from the pump? Do I have to worry about mill scale coming off over the years in this tank? I'm thinking it's going to be fine I just need to wire wheel the inside welds to remove any bits of wire and junk. Recommendations on pressure testing the tank once I weld the top? Saw that someone recommend shop air to pressurize and go around with soap and water to find bubbles.

Oh, that I don't know. I know it's tight, so the ram doesn't wiggle and feel sloppy (my last one was loose as a goose! and I say a flaw in engineering). I used to know the clearances but it's been awhile since it's been built and I forgot.I was talking about the spacing where the push plate and I beam meet underneath.

I was looking on your build thread before I started mine and that's a pretty sweet setup you made there. Dumb question but with the weld on bungs do you put the bigger side in the tank? I bought my parts from Split-Ez website and I want to clarify which way the bungs go in.The strainer is mounted BEFORE the pump in the tank. The filter is on the return before it goes back into the tank. You don't want to starve the pump and I've seen people do that by putting the filter on the suction to the pump. The strainer is just a low restriction filter to get the big stuff. Could become a restriction if you had all kinds of junk in there and never cleaned it.

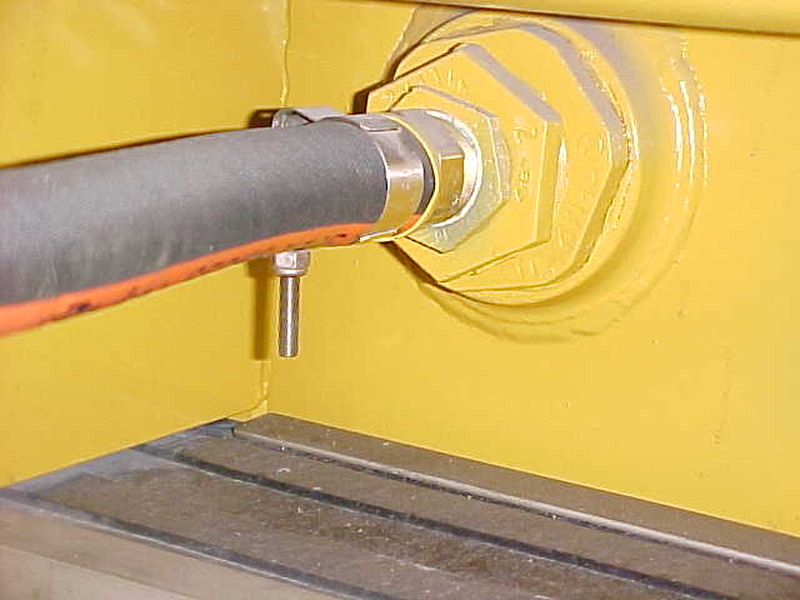

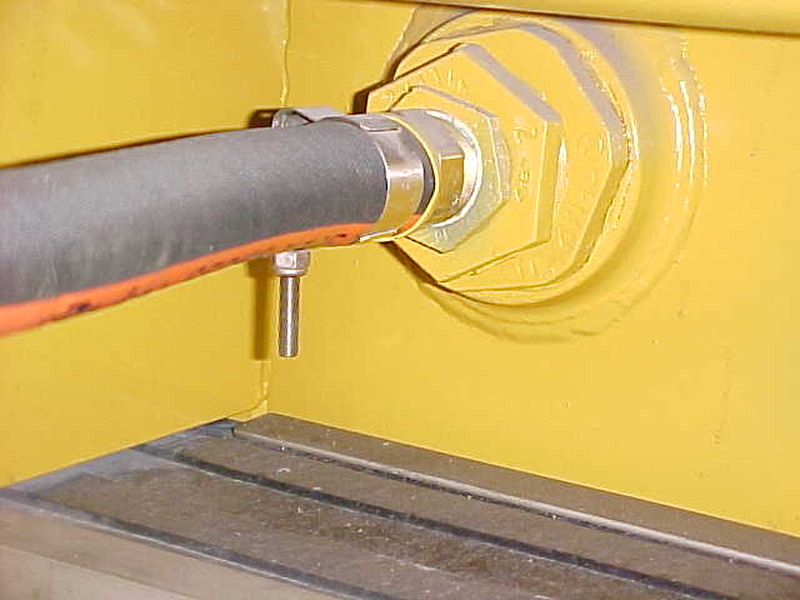

Close up of suction line from tank to pump. Welded on bung and strainers neck it down. Heavy band clamps keep the spiral suction hose in place. Way better than standard auto clamps.

It's a straight. short run to the pump.

The more steel the better has been my motto in reference to your beam. I use the Box beam slide as I like it better than an I beam. I've never had to repair any I've built. Can't say that for others Ibeams Wear on them is basically non existant but a long slide had tons to do with that.

the flange goes on the outside...I was looking on your build thread before I started mine and that's a pretty sweet setup you made there. Dumb question but with the weld on bungs do you put the bigger side in the tank? I bought my parts from Split-Ez website and I want to clarify which way the bungs go in.

I was looking on your build thread before I started mine and that's a pretty sweet setup you made there. Dumb question but with the weld on bungs do you put the bigger side in the tank? I bought my parts from Split-Ez website and I want to clarify which way the bungs go in.

and SLOW speed...Hole saws work fine but MAKE sure you keep plenty of oil on them and don't overheat them. They last a long time if you keep the oil and coolness. If not, you won't even make one hole before it's junk.

cantoo... is that a millermatic 200?Looks good. The pusher design is different than what most use. I didn't bother with a diffuser but I did dump the oil in at the bottom. I think I have enough storage that circulating it won't be an issue. I don't work that hard or fast. My Speeco gets too hot to touch but I'm trying to wreck it. 36" cylinder for scale. Ports are in 1st pic on left side of tank. Tank is about 14"x14"x 36" long.

View attachment 458625

Yes it is. It got the machine from a friend and it wouldn't more than strike an arch and wouldn't keep feeding wire. It had a whip for a Lincoln machine not a Miller. Ever since changing it out it has been a great machine.cantoo... is that a millermatic 200?

Yeah I saw yours is a 200...its a mm200 "vintage" isn't it? It's definitely a late model...late 80's early 90's..Yes it is. It got the machine from a friend and it wouldn't more than strike an arch and wouldn't keep feeding wire. It had a whip for a Lincoln machine not a Miller. Ever since changing it out it has been a great machine.

I looked at yours again...looks like a late model black face 200...not a vintage model...Yeah I saw yours is a 200...its a mm200 "vintage" isn't it? It's definitely a late model...late 80's early 90's..

Anyways I was actually talking about cantoo's machine...looks like a black face mm200 with a dual cylinder rack?

I have a black face 200 with all the options...best mig machine I've ever used...best mig according to alot of others too...