The scoring could have come from many different ways. An air leak such as bad seals, bad intake boot, bad impulse grommet, bad base gasket.

Or it could have come from as simple as bad gas, too lean on the carb adjustments, bad fuel line, and the most common is dried out diaphragms in the carb, making it run lean.

I can't remember for sure, having a brain fart at the moment.... that piston is either 45mm or 46mm (somebody will answer shortly) and is very difficult to find for the closed port. The closed port system on the Husky 55 is very sought after. Most were open port.

You can remove the aluminum transfer with muriatic acid and some fine sand paper.

Or if you want, you can send me the jug and I will clean it for you free of charge. I'll put it in the ultra sonic cleaner and bead blast it also.

There is no promise it will clean up perfectly, if there is a scratch above the exhaust port that is through the plating... there's nothing you can do.

I've done many jugs for many members here, and everybody has been happy. Having everything set up here, it only takes me minutes.

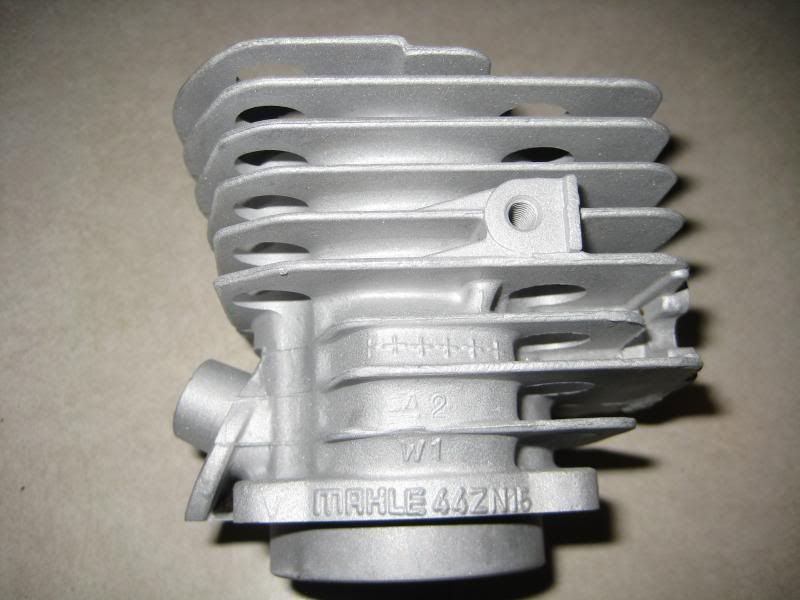

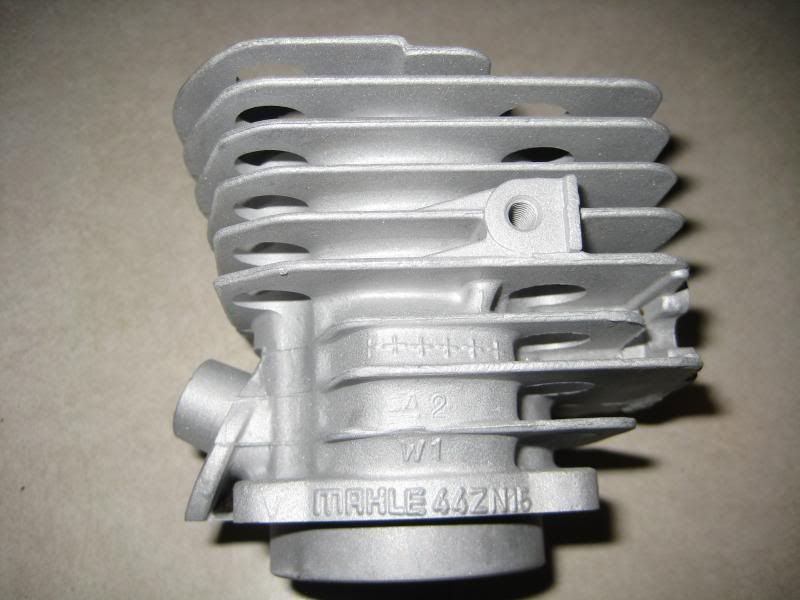

I did this 45mm Jonsered 590 jug today. It had some aluminum transfer and light scoring. The jug was completely black, the cooling fins were 50% packed with grime. It looked horrible and was unusable.

I put it in the US cleaner, acid cleaned it, lightly honed it, then bead blasted it. It came out very nice. Let me know if you want me to do yours for ya.

Or it could have come from as simple as bad gas, too lean on the carb adjustments, bad fuel line, and the most common is dried out diaphragms in the carb, making it run lean.

I can't remember for sure, having a brain fart at the moment.... that piston is either 45mm or 46mm (somebody will answer shortly) and is very difficult to find for the closed port. The closed port system on the Husky 55 is very sought after. Most were open port.

You can remove the aluminum transfer with muriatic acid and some fine sand paper.

Or if you want, you can send me the jug and I will clean it for you free of charge. I'll put it in the ultra sonic cleaner and bead blast it also.

There is no promise it will clean up perfectly, if there is a scratch above the exhaust port that is through the plating... there's nothing you can do.

I've done many jugs for many members here, and everybody has been happy. Having everything set up here, it only takes me minutes.

I did this 45mm Jonsered 590 jug today. It had some aluminum transfer and light scoring. The jug was completely black, the cooling fins were 50% packed with grime. It looked horrible and was unusable.

I put it in the US cleaner, acid cleaned it, lightly honed it, then bead blasted it. It came out very nice. Let me know if you want me to do yours for ya.